Motorcycle tire semi-hot melt adhesive and preparation method thereof

A motorcycle tire, semi-hot melting technology, applied in the direction of adhesives, adhesive types, acrylonitrile butadiene styrene polymer adhesives, etc., can solve the problem of poor performance of rapid hot tires and can not meet the needs of car enthusiasts Tire needs and other issues, to achieve good hot-melt performance, good start-up acceleration performance and curve safety performance during driving, and improve the effect of tear strength and tensile strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

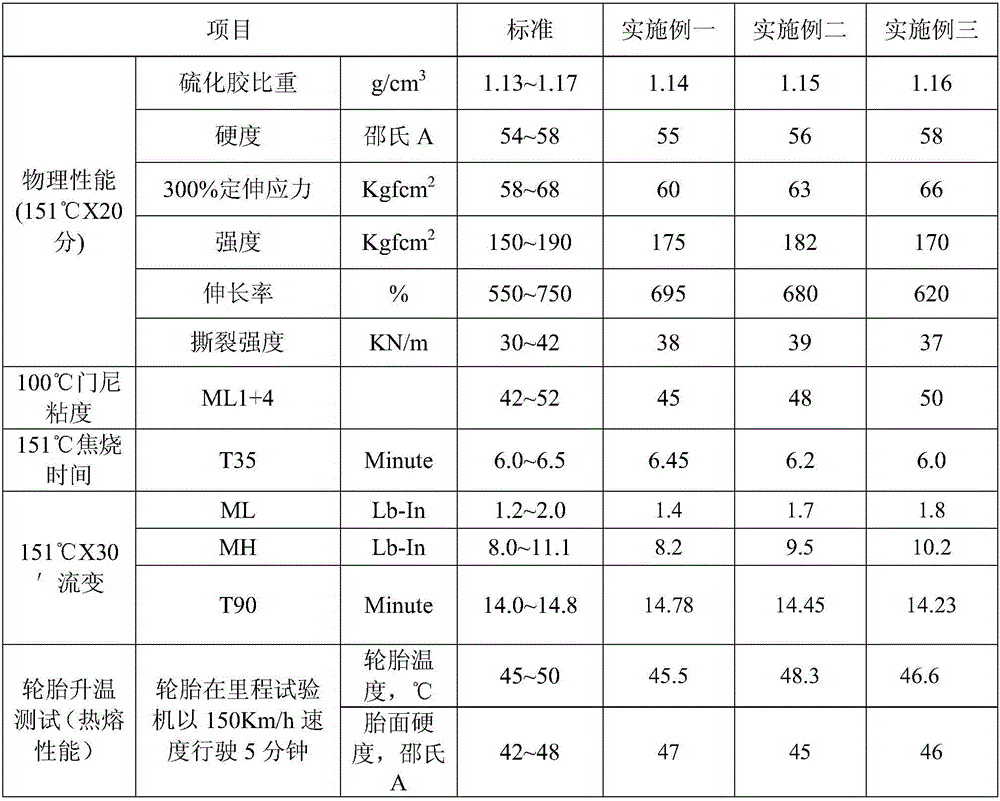

Examples

Embodiment 1

[0022] The preparation method of semi-hot melt adhesive for motorcycle tires includes the following steps:

[0023] (1) One stage mixing: start the internal mixer, the rotor speed of the internal mixer is 35rmp, the pressure of the top bolt on the rubber material is 0.5MPa, the temperature of the mixing chamber is 45℃, the temperature of the rotor is 40℃, and the glue discharge temperature At 150℃, 114.1 parts of oil-extended styrene butadiene rubber, 17 parts of styrene-butadiene-acrylonitrile copolymer, 2 parts of zinc oxide, 1.5 parts of stearic acid, 1.5 parts of antioxidant 4020, 2.5 parts by weight Protective wax, 1 part of additives, 1 part of homogenizer, and 70 parts of carbon black are put into the internal mixer at the same time. The rotor is rotated in the mixing room for 55 seconds, and then 12 parts of aromatic oil are added to the mixing room and proceed. Mixing for 25 seconds, the top plug floats once to turn the compound in the mixing chamber, then press the top ...

Embodiment 2

[0027] The preparation method of semi-hot melt adhesive for motorcycle tires includes the following steps:

[0028] (1) One stage mixing: start the internal mixer, the rotor speed of the internal mixer is 38rmp, the pressure of the top bolt on the rubber is 0.55MPa, the temperature of the mixing chamber is 40℃, the temperature of the rotor is 35℃, and the glue discharge temperature At 155°C, 116.9 parts of oil-extended styrene butadiene rubber, 15 parts of styrene-butadiene-acrylonitrile copolymer, 2.5 parts of zinc oxide, 1.8 parts of stearic acid, 1.6 parts of antioxidant 4020, 3 parts by weight Protective wax, 1.5 parts of additives, 1.5 parts of homogenizer, and 73 parts of carbon black are put into the internal mixer at the same time. The rotor is used for mixing in the mixing room for 60 seconds, and then 15 parts of aromatic oil are added to the mixing room. Mixing for 30 seconds, the top plug floats once to turn over the compound in the mixing chamber, then press the top ...

Embodiment 3

[0032] The preparation method of semi-hot melt adhesive for motorcycle tires includes the following steps:

[0033] (1) One stage mixing: start the internal mixer, the rotor speed of the internal mixer is 40 rpm, the pressure of the top bolt on the rubber material is 0.6 MPa, the mixing chamber temperature is 35 ℃, the rotor temperature is 30 ℃, and the glue discharge temperature At 160°C, 119.6 parts of oil-extended styrene butadiene rubber, 13 parts of styrene-butadiene-acrylonitrile copolymer, 3 parts of zinc oxide, 2 parts of stearic acid, 1.8 parts of antioxidant 4020, 3.5 parts by weight The wax protector, 2 additives and 2 homogenizers, 75 carbon black are put into the internal mixer at the same time, the rotor is rotated in the mixing chamber for 60 seconds, and then 16 parts of aromatic oil are added to the mixing chamber and mixed 35 Second, the top plug floats once to turn the compound in the mixing chamber, then press down the top plug to continue mixing for 105 secon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com