Acrylic acid series hot melt adhesive and preparation method thereof

A hot-melt adhesive, acrylic technology, applied in the direction of adhesive types, ester copolymer adhesives, amide/imide polymer adhesives, etc., can solve the problem of low 180°peel strength, inconvenient use, sticky Solve problems such as poor junction performance, achieve the effect of increasing cohesive strength and adhesion performance, low glass transition temperature, and good adhesion performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

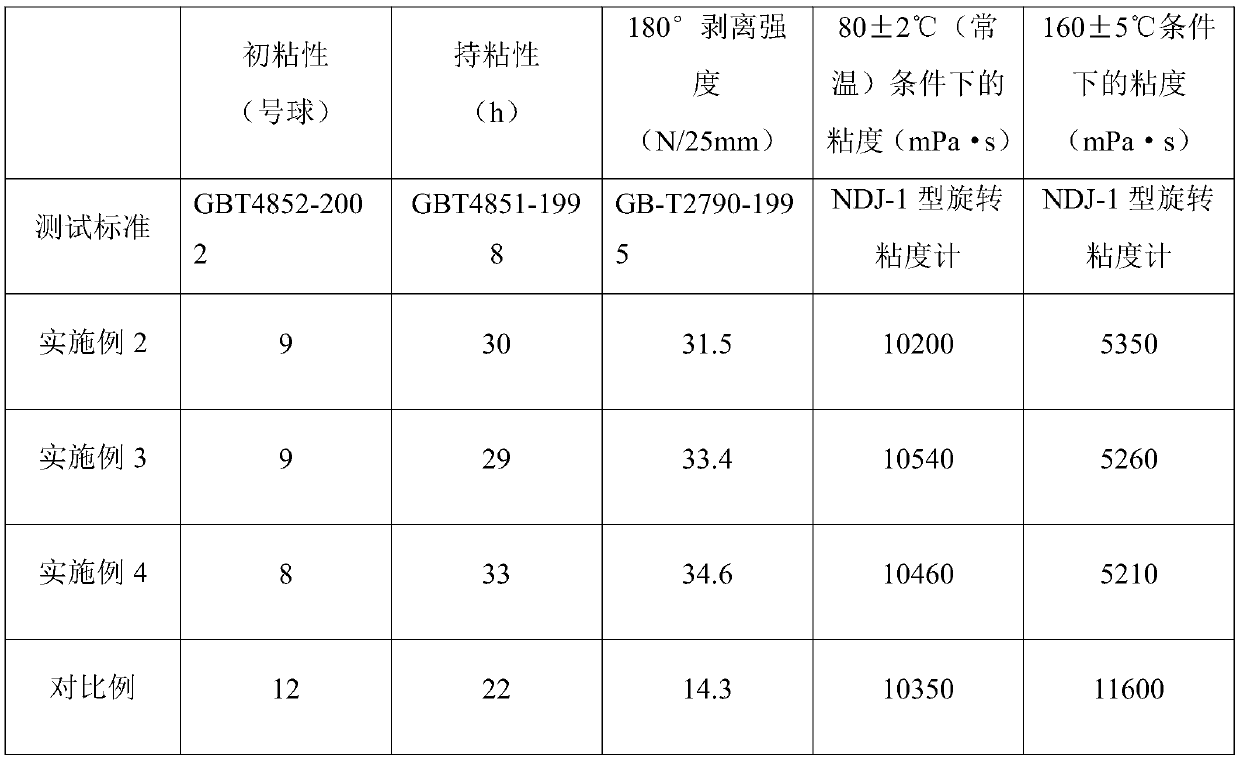

Examples

Embodiment 1

[0036] An acrylic hot-melt adhesive, made of the following raw materials in parts by weight: 60-95 parts of 2-ethylhexyl acrylate, 20-26 parts of vinyl acetate, 13-16 parts of hydroxypropyl acrylate, acrylamide 1.5 to 6 parts, 5.5 to 8 parts of 2-acetaminoacrylic acid, and 1.6 to 1.9 parts of azobisisobutyronitrile.

[0037] Preferably, the acrylic hot melt adhesive is made of raw materials comprising the following parts by weight: 82 parts of 2-ethylhexyl acrylate, 23.5 parts of vinyl acetate, 14.5 parts of hydroxypropyl acrylate, 3.7 parts of acrylamide, 2 - 7.2 parts of acetaminoacrylic acid, 1.75 parts of azobisisobutyronitrile.

[0038] The present invention also provides a kind of preparation method of described acrylic hot-melt adhesive, comprises the following steps:

[0039] S1: Weigh respectively by weight: 2-ethylhexyl acrylate, vinyl acetate, hydroxypropyl acrylate, acrylamide, 2-acetamidoacrylic acid, azobisisobutyronitrile;

[0040] S2: uniformly mixing 2-ethyl...

Embodiment 2

[0048] An acrylic hot-melt adhesive, made from the following raw materials in parts by weight: 60 parts of 2-ethylhexyl acrylate, 20 parts of vinyl acetate, 13 parts of hydroxypropyl acrylate, 1.5 parts of acrylamide, 2-acetic acid Aminoacrylic acid 5.5 parts, azobisisobutyronitrile 1.6 parts.

[0049] In the present embodiment, the preparation method of described acrylic hot melt adhesive comprises the following steps:

[0050] S1: Weigh respectively by weight: 2-ethylhexyl acrylate, vinyl acetate, hydroxypropyl acrylate, acrylamide, 2-acetamidoacrylic acid, azobisisobutyronitrile;

[0051] S2: uniformly mixing 2-ethylhexyl acrylate, vinyl acetate, hydroxypropyl acrylate, acrylamide and 2-acetaminoacrylic acid to obtain a mixed monomer;

[0052] S3: Dissolving azobisisobutyronitrile with 78% mixed monomers to obtain azobisisobutyronitrile monomer solution, which is set aside;

[0053] S4: Put the remaining mixed monomers into the reaction kettle, stir, raise the temperature...

Embodiment 3

[0059] An acrylic hot-melt adhesive, made of the following raw materials by weight: 95 parts of 2-ethylhexyl acrylate, 26 parts of vinyl acetate, 16 parts of hydroxypropyl acrylate, 6 parts of acrylamide, 2-acetic acid 8 parts of aminoacrylic acid, 1.9 parts of azobisisobutyronitrile.

[0060] In the present embodiment, the preparation method of described acrylic hot melt adhesive comprises the following steps:

[0061] S1: Weigh respectively by weight: 2-ethylhexyl acrylate, vinyl acetate, hydroxypropyl acrylate, acrylamide, 2-acetamidoacrylic acid, azobisisobutyronitrile;

[0062] S2: uniformly mixing 2-ethylhexyl acrylate, vinyl acetate, hydroxypropyl acrylate, acrylamide and 2-acetaminoacrylic acid to obtain a mixed monomer;

[0063] S3: Dissolving azobisisobutyronitrile with 82% mixed monomers to obtain azobisisobutyronitrile monomer solution for later use;

[0064] S4: Put the remaining mixed monomers into the reaction kettle, stir, raise the temperature to 67°C, start...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com