Method for synthesizing glucose modified polyvinylalcohol resin

A polyvinyl alcohol resin, polyvinyl alcohol technology, applied in the direction of adhesives, etc., can solve the problem of not being able to completely remove aldehydes, and achieve the effect of improving mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

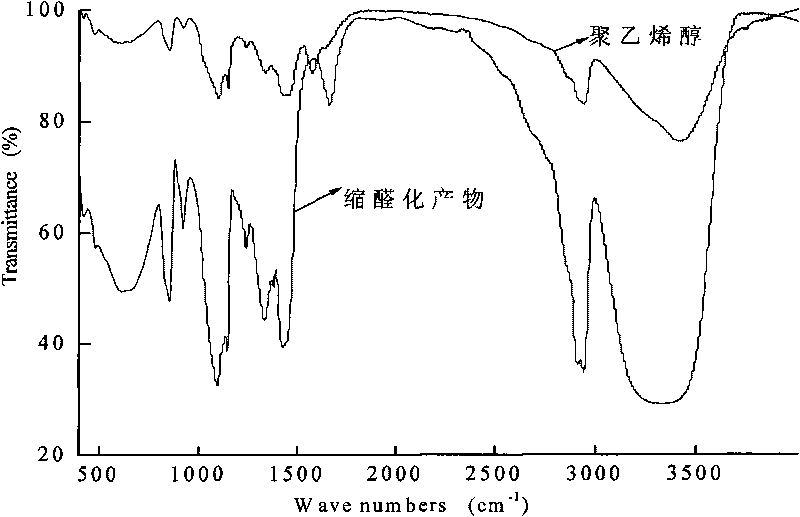

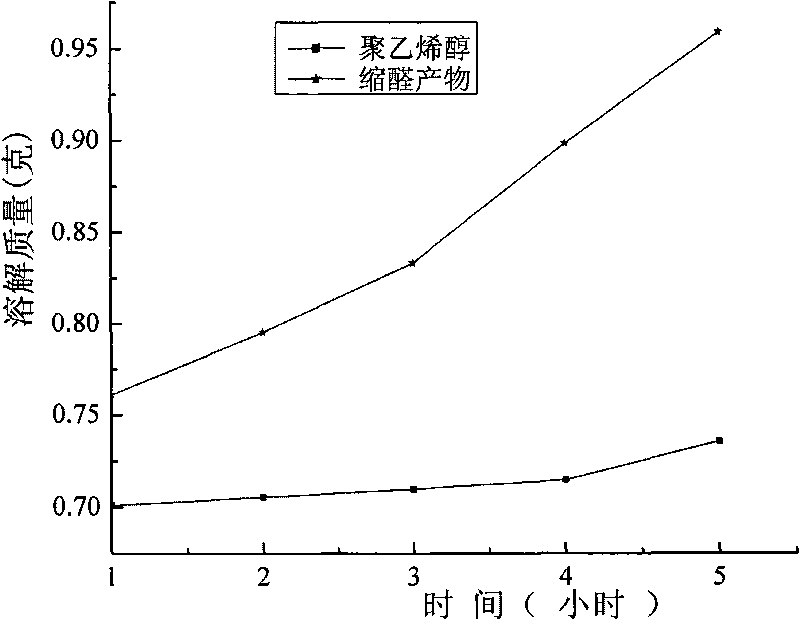

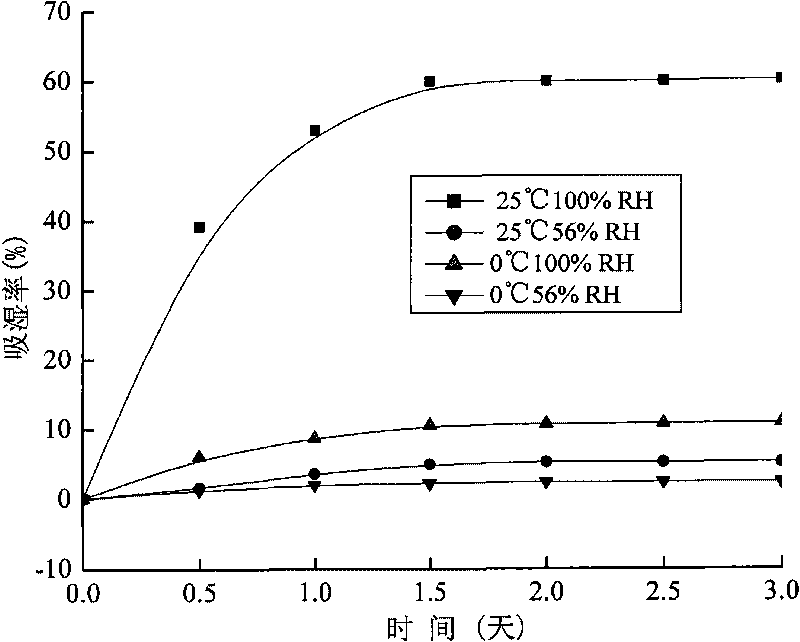

[0035] Put 20 parts of polyvinyl alcohol (1799) and 80 parts of water into the pressure reactor, stir at 90℃~95℃ for 1~2 hours, make the polyvinyl alcohol completely dissolve in the water, and prepare 20% polyethylene Alcohol solution, then cool to 80℃ and add 44 parts of anhydrous glucose (the mass ratio of polyvinyl alcohol, water and glucose is 1:4:2.2, the molar ratio of polyvinyl alcohol hydroxyl group and glucose is 2:1), while stirring While adding a mixed acid with a mass fraction of 1.5% of the total mass of the system as a catalyst, the mixed acid is concentrated hydrochloric acid and concentrated phosphoric acid with a mass ratio of 1:2. After the catalyst is uniformly dispersed, the reaction temperature is increased to 90°C and the acetalization reaction is carried out for 2 hours The product is then neutralized to neutrality to obtain an aqueous solution of polyvinyl dextrose modified resin adhesive. Then it is cooled, salted out and dried to obtain an acetalized r...

Embodiment 2

[0037] According to Example 1, only the mass ratio of polyvinyl alcohol, water and glucose was changed to 1:9:2.2 to prepare a 10% polyvinyl alcohol aqueous solution, the mass ratio of mixed acid concentrated hydrochloric acid and concentrated phosphoric acid was 1:1, and the reaction temperature At 80°C, the reaction time is 1 hour, and the acetal degree of the obtained polyvinyl alcohol glucose modified resin is 25.2%. The softening point and tensile strength performance of the prepared acetalized resin samples were tested. The results are shown in Table 1.

Embodiment 3

[0039] According to Example 1, only the mass ratio of polyvinyl alcohol, water and glucose was changed to 1:19:1.44 to prepare a 5% polyvinyl alcohol aqueous solution, the mass ratio of mixed acid concentrated hydrochloric acid and concentrated phosphoric acid was 1:1, and the reaction temperature At 100°C, the reaction time was 2 hours, and the obtained polyvinyl alcohol glucose thermoplastic resin had an acetal degree of 31.5%. The softening point and tensile strength performance of the prepared acetalized resin samples were tested. The results are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com