Composite pipe made of non-cross-linking refractory polyethylene and cross-linking polyethylene

A technology of high temperature-resistant polyethylene and cross-linked polyethylene is applied in the field of composite pipes, which can solve the problems of high price and difficulty in pipe promotion and application, and achieve the effects of good hot melt, high creep resistance and environmental protection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

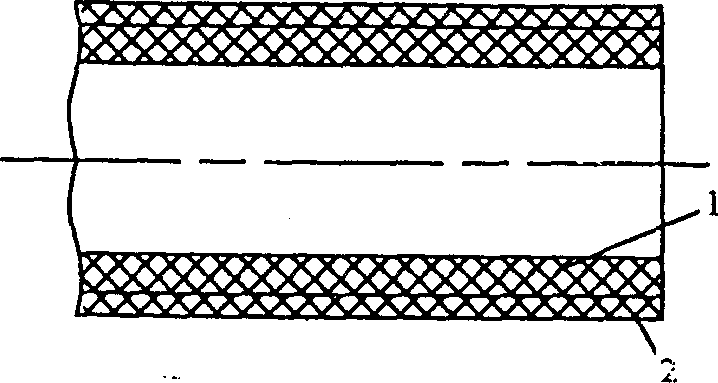

[0025] figure 1 A schematic structural diagram of Embodiment 1 of the present invention is given. see figure 1 The outer periphery of the cross-linked polyethylene inner layer 1 has a non-cross-linked high-temperature-resistant polyethylene outer layer 2 compounded therewith.

Embodiment 2

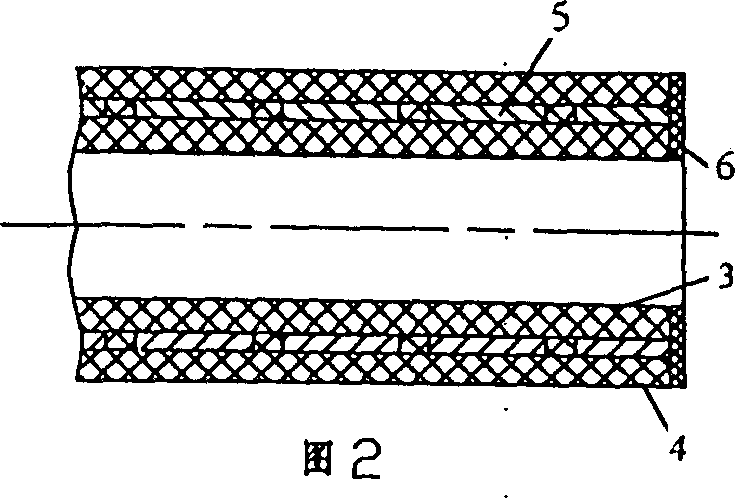

[0027] figure 1 A schematic structural diagram of Embodiment 2 of the present invention is given. Referring to Fig. 2, there is a metal skeleton reinforcing layer 5 welded by steel plates with holes between the cross-linked polyethylene inner layer 3 and the non-cross-linked polyethylene outer layer 4. The inner layer and the outer layer cover and compound the metal skeleton reinforcing body through the holes in the metal skeleton reinforcing layer. There are end faces 6 formed by bonding resin plugging at both ends of the composite.

Embodiment 3

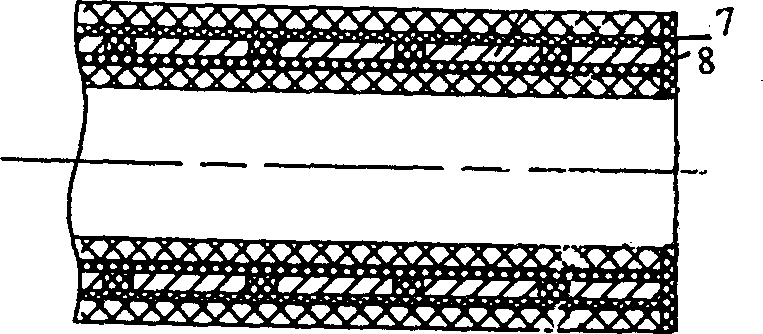

[0029] image 3 A schematic structural diagram of Embodiment 3 of the present invention is given. Embodiment 3 is basically the same as Embodiment 2. The difference is that there are adhesive layers 7 and 8 between the metal skeleton reinforcement and the inner and outer layers respectively.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com