Halogen-free low-dielectric-loss epoxy resin composition and prepreg and laminated board prepared by using halogen-free low-dielectric-loss epoxy resin composition

A technology of epoxy resin and prepreg, which is applied in the direction of synthetic resin layered products, lamination, lamination devices, etc., can solve the problem of high frequency of operation signals, increase of polar groups in molecular structure, material dielectric rate and High water absorption and other problems, to achieve the effect of high performance, low dielectric constant and dielectric loss, low expansion coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

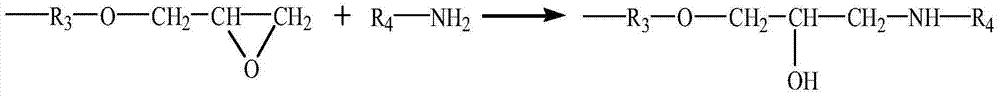

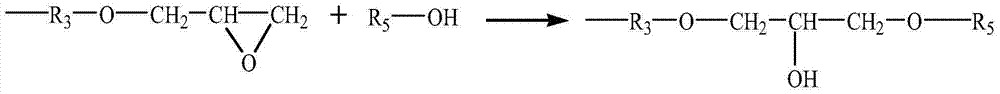

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] First, weigh 15g of SMA resin (brand name is SMA-1000 ((n / m=8 / 1))), 193g of epoxy resin (including 30g of dicyclopentadiene epoxy resin, 60g of phosphorus-containing phenolic epoxy resin, isocyanate Type epoxy resin 100g, four-functional epoxy resin 3g), curing agent A 90g (of which dicyandiamide 0.5g, bisphenol A type phenolic resin 20g, phosphorus-containing phenolic resin 69.5g), curing agent B (that is, active esters curing agent) 70g, filler 100g (wherein aluminum hydroxide 70g, silicon dioxide 30g), curing accelerator 0.31g (both are 2-methylimidazole), coupling agent 1g (both are silane coupling agent, its brand is Z-6020), solvent 100g (wherein propylene glycol methyl ether 90g, butanone 10g).

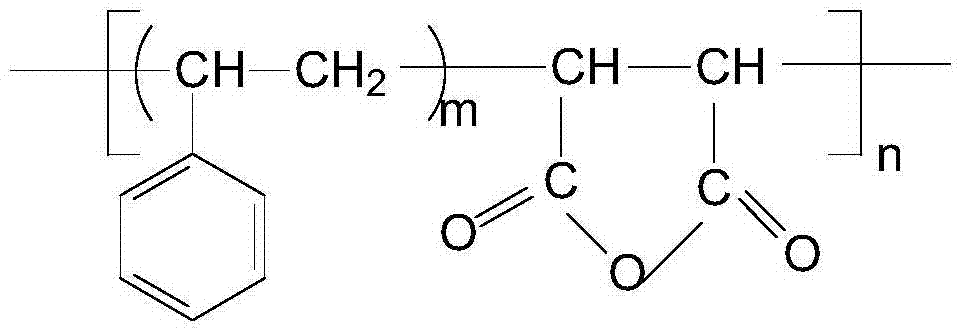

[0038] The structural formula of above-mentioned active ester curing agent is as follows:

[0039]

[0040] where R 1 is an aliphatic group, R 2is an aromatic group. The trade mark of the active ester curing agent used in this embodiment is HPC-8000.

[0041] The...

Embodiment 2

[0047] First, weigh 15g of SMA resin (brand name is SMA-3000 (n / m=10 / 3)), 193g of epoxy resin (including 30g of dicyclopentadiene epoxy resin, 60g of bisphenol A type epoxy resin, bisphenol F type epoxy resin 100g, ortho-methyl phenolic type epoxy resin 3g), curing agent A 87.5g (wherein diaminodiphenylmethane 0.5g, bisphenol A type phenolic resin 23g, p-xylidine 64g), Curing agent B (i.e. active ester curing agent) 60g, filler 92g (of which kaolin 65g, silicon dioxide 27g), curing accelerator 0.38g (both 2-methylimidazole), coupling agent 0.92g (both silane Coupling agent, its trade mark is Z-6020), solvent 95g (wherein propylene glycol methyl ether 90g, butanone 5g).

[0048] The structural formula of above-mentioned active ester curing agent is as follows:

[0049]

[0050] where R 1 is an aliphatic group, R 2 is an aromatic group. The trade mark of the active ester curing agent used in this embodiment is HPC-8000.

[0051] Then, prepare the halogen-free low dielect...

Embodiment 3

[0057] First, weigh 15g of SMA resin (brand name is EF60 (12 / 5)), 193g of epoxy resin (33g of biphenyl type epoxy resin, 60g of bisphenol A novolac type epoxy resin, 100g of isocyanate type epoxy resin), solidify Agent A 86.5g (including 0.5g of diaminodiphenylsulfone, 26g of diaminodiphenylmethane, 60g of phosphorus-containing phenolic resin), 50g of curing agent B (ie active ester curing agent), 84g of filler (including 61g of mica powder , silicon dioxide 23g), flame retardant 3g (both 10-(2,5-dihydroxyphenyl)-9,10-dihydro-9-oxa-10-phosphinephenanthrene-10-oxide), Curing accelerator 0.83g (both are 2-ethyl-4-methylimidazole), coupling agent 0.84g (both are silane coupling agent, its trade mark is Z-6020), solvent 95g (wherein propylene glycol methyl ether 90g, N,N-dimethylformamide 5g).

[0058] The structural formula of above-mentioned active ester curing agent is as follows:

[0059]

[0060] where R 1 is an aliphatic group, R 2 is an aliphatic group. The trade ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com