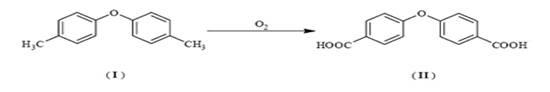

Method for preparing 4, 4'-diphenyl ether dicarboxylic acid

A technology of diphenyl ether dicarboxylic acid and dimethyl diphenyl ether, which is applied in the field of preparing 4,4'-diphenyl ether dicarboxylic acid, can solve the problems of long reaction time, cumbersome operation, high cost, etc., and achieve less catalyst consumption , post-processing is simple, the effect of cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1)

[0024] This example is the preparation of 4,4'-diphenyl ether dicarboxylic acid by the normal pressure method (the reaction vessel is connected to the atmosphere during the reaction), which has the following steps:

[0025] ①Add 12g of the reactant 4,4'-dimethyldiphenyl ether, 1g of the catalyst cobalt acetate tetrahydrate, 0.75g of the catalyst manganese acetate, and 0.6g of the oxidation additive sodium bromide into a 100mL reaction flask, and then 50 g of organic acid propionic acid was added as a solvent.

[0026] ②By bubbling, quickly pass excess oxygen into the reaction device below the liquid level, and heat to 120°C to carry out the oxidation reaction of 4,4'-diphenyl ether dicarboxylic acid for 4 hours until a large amount of white solids are precipitated.

[0027] ③ Cool the material after the oxidation reaction to 20°C, then filter it with suction, then wash it twice with propionic acid, then wash it with water three times, and finally dry it in vacuum to obtain 14g...

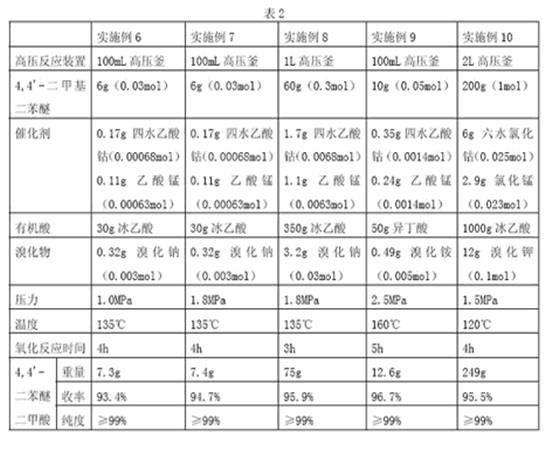

Embodiment 2~ Embodiment 5)

[0029] The preparation method of each embodiment is basically the same as that of Example 1, and the differences are shown in Table 1.

[0030]

[0031]

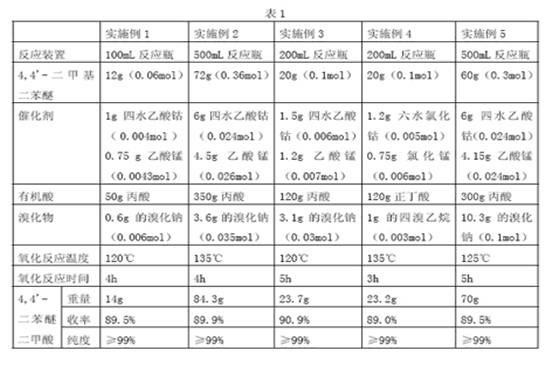

Embodiment 6)

[0033] This example is the preparation of 4,4'-diphenyl ether dicarboxylic acid by the high-pressure method (the reaction vessel is in a closed state during the reaction), which has the following steps:

[0034] ①Add 6g of the reactant 4,4'-dimethyldiphenyl ether, 0.17g of the catalyst cobalt acetate tetrahydrate, 0.11g of the catalyst manganese acetate, and 0.32g of the oxidation additive sodium bromide into a 100mL autoclave, Then 30 g of the organic acid glacial acetic acid was added as a solvent.

[0035] ②Introduce excess oxygen into the autoclave and pressurize to 1.0MPa to generate 4,4'-diphenyl ether dicarboxylic acid oxidation reaction, while stirring and heating to 135°C, the pressure in the autoclave immediately drops rapidly, when the pressure When it drops to 0.5MPa, re-introduce oxygen and pressurize to 1.0MPa, repeat this cycle 2 to 4 times until the pressure in the autoclave is maintained for 1 hour and no longer drops.

[0036] ③ Cool the material after the o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com