Preparation method of polyimide nanometer lithium ion battery diaphragm and product thereof

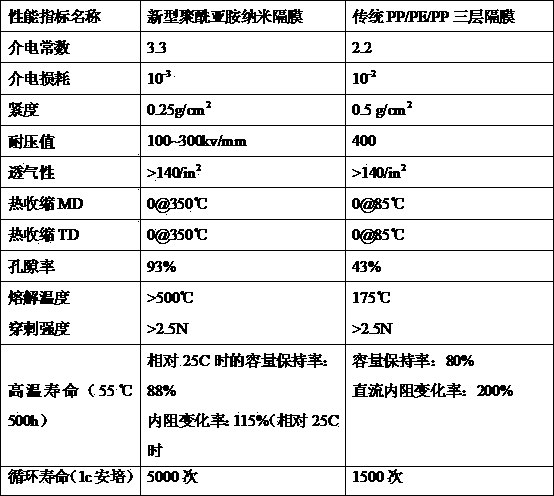

A lithium-ion battery, polyimide technology, applied in nanotechnology, nanotechnology, battery pack components, etc., can solve the problems of uneven micropore diameter of diaphragm, complex diaphragm processing, affecting battery performance, etc., and achieve melting temperature. Excellent, easy to process, life-enhancing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described in further detail below through specific examples.

[0028] This embodiment is a preparation method of a polyimide nano-lithium ion battery separator, which comprises the steps of:

[0029] a) Preparation of polyamic acid solution: materials for preparing polyamic acid solution include 4,4'-diaminodiphenyl ether (ODA), 4,4'-oxydiphthalic anhydride (ODPA) and dimethyl Acetamide (DMAc), in which 4,4'-diaminodiphenyl ether (ODA) and 4,4'-oxydiphthalic anhydride (ODPA) have a ratio of 1:1, dimethylacetamide Amide was used as the reaction medium, and the solid content of polyamic acid in the solution was 20 wt%. Dissolve a certain amount of ODA in DMAC at room temperature, and keep stirring until the ODA is completely dissolved and becomes a colorless and transparent solution, then add an equal amount of ODPA to the solution in batches, and when it reaches the equivalent point, the poly The viscosity of the amic acid increases rapidl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com