Manufacturing method of F-level electromagnetic wire

A manufacturing method and electromagnetic wire technology, applied in the direction of cable/conductor manufacturing, circuits, electrical components, etc., can solve the problems of electromagnetic wire pollution, high energy consumption, etc., and achieve the effect of eliminating emissions, pollution-free production process, and eliminating pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

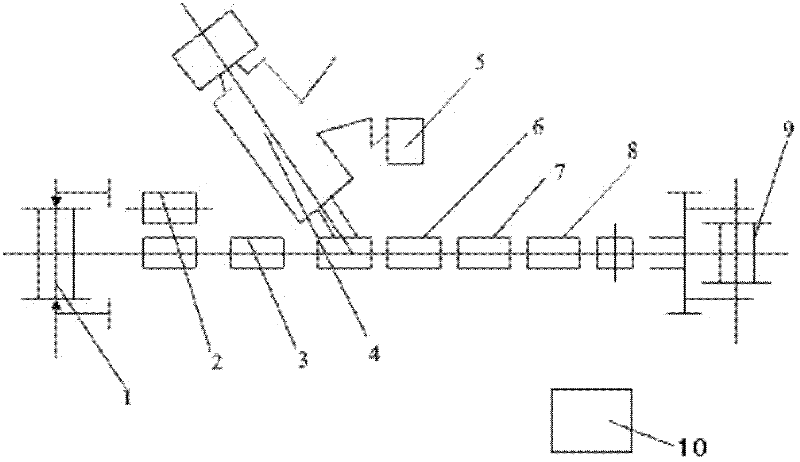

Image

Examples

Embodiment Construction

[0016] The production method of the F-class electromagnetic wire of the present embodiment comprises: making the nano-materials such as silicon dioxide, aluminum oxide, aluminum nitride and the like through activation treatment on the surface into pellets; the pellets are heated (70-75 ℃) Vacuum drying for not less than 6 hours to remove volatile matter and moisture in the pellets.

[0017] The pellets include: 37wt% of silicon dioxide, 17wt% of aluminum oxide and 46wt% of aluminum nitride; the pellets are added to polyester resin and stirred evenly to obtain insulating resin for use.

[0018] Put the insulating resin into the hopper of the extruder and start the extruder; the extruder heats the insulating resin to 180-240°C, 260-270°C and 270-275°C in sections. When the pellet reaches 270-275°C, it is in a high-temperature viscous flow state, and is extruded to the machine head; the material flowing to the machine head is extruded from the die sleeve through the annular gap b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com