Ethylene-propylene-diene monomer rubber foam material and preparation method thereof

A technology of EPDM rubber and foaming materials, which is applied in the field of foaming materials, can solve the problems that the mechanical properties of rubber foaming materials are not as good as rubber and are easy to break, and achieve low density, good aging resistance and high chemical stability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0029] The present invention also provides a preparation method of EPDM foamed material, which is characterized in that the method comprises: putting the raw material of the foamed material into an open mill according to the formula of the foamed material provided by the present invention Mixing, the product obtained from mixing is placed for 12-48 hours and then re-milled, and the product obtained from the re-milling is sent to a flat vulcanizer for pressurized vulcanization and pressure-relieving foaming in sequence.

[0030] The steps of mixing, re-milling, pressure vulcanization and pressure-relieving foaming are routinely used by those skilled in the art. For example, the conditions of said mixing and re-milling are respectively: the temperature is 150-210°C, and the time is 3-15 Minutes, the conditions of the pressure vulcanization are: the pressure is 5-20 MPa, the temperature is 150-210 ° C, and the time is 5-40 seconds, the conditions of the pressure relief foaming are...

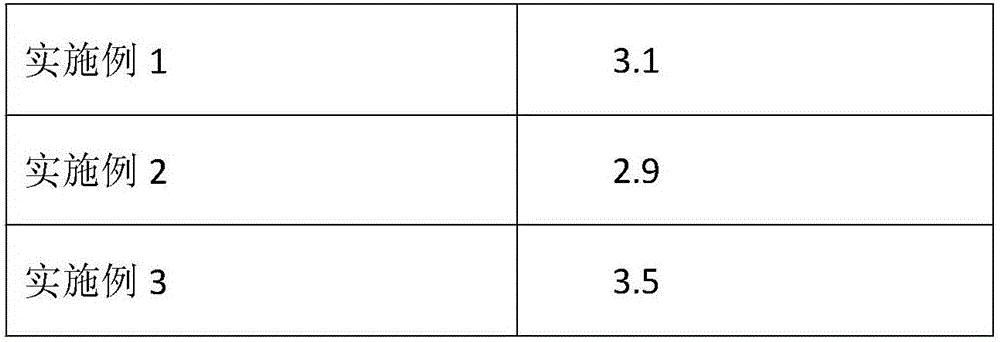

Embodiment 1

[0035] 100 parts by weight of EPDM rubber, 5 parts by weight of nano silica gel of 50 nanometers, 3 parts by weight of 2-mercaptobenzothiazole, 1 part by weight of hydrogenated vegetable oil, 3 parts by weight of azodicarbonamide, 1 part by weight of sulfur, 2 parts by weight of lanthanum oxide and 5 parts by weight of stearic acid are put into an open mill and kneaded at 150°C for 3 minutes. Refined for 3 minutes, put the product obtained by re-refining into a flat vulcanizer, pressurize and vulcanize for 5 seconds at 5 MPa at a temperature of 150°C, and foam at a temperature of 150°C for 45 seconds after releasing the pressure to normal pressure to obtain ternary Ethylene-propylene rubber foam material CL-1 was tested for tensile strength, and the results are shown in Table 1.

Embodiment 2

[0037] The EPDM rubber of 120 parts by weight, the nano silica gel of 10 parts by weight of 200 nanometers, the dithiuram tetrasulfide of 5 parts by weight, the hydrogenated vegetable oil of 4 parts by weight, the azodicarbonamide of 8 parts by weight, the azodicarbonamide of 3 parts by weight The sulfur of 5 parts by weight, the cerium oxide of 5 parts by weight and the stearic acid of 10 parts by weight are put into an open mill at 170°C and kneaded for 10 minutes, and the product obtained by kneading is placed for 24 hours and then remilled at 190°C for 8 Minutes, the product obtained by re-refining is sent to a flat vulcanizing machine and vulcanized under pressure at 10 MPa and a temperature of 190 ° C for 20 seconds. After the pressure is released to normal pressure, it is foamed at a temperature of 190 ° C for 80 seconds to obtain EPDM The rubber foam material CL-2 was tested for tensile strength, and the results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com