Method for manufacturing insulation structure of rotor coil of wind driven generator

A wind turbine and rotor coil technology, applied in the direction of laying solid insulation, etc., can solve the problems of accelerated motor insulation aging, achieve the effect of reducing volume and weight, improving reliability and service life, and strengthening the ability of insulation damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

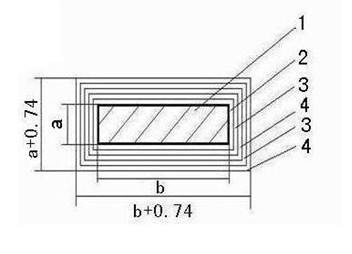

[0015] Depend on figure 1 It is known that on the formed rotor bare copper coil 1, a layer of 0.025mm thick domestic corona-resistant polyimide film tape 2 is half-stacked; Mica tape 3 with less glue reinforced on one side of the film; then half-stacked with a layer of 0.025mm thick domestic corona-resistant polyimide film tape 2; then half-stacked with a layer of 0.11mm thick domestic corona-resistant polyimide Mica tape 3 with less glue reinforced on one side of the film; and a layer of activated polytetrafluoroethylene film tape 4 with a thickness of 0.05 mm and an insulation thickness of 0.74 mm.

Embodiment 2

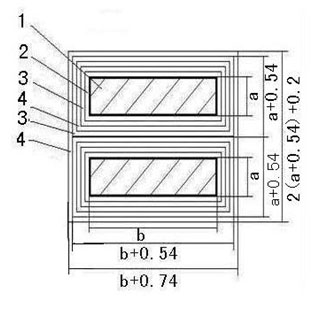

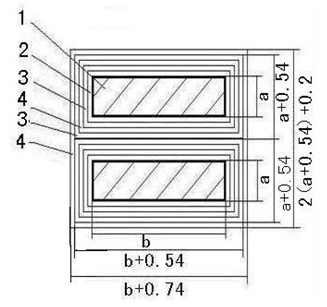

[0016] Embodiment 2: by figure 2 It is known that on the two formed rotor bare copper coils 1, a layer of 0.025mm thick domestic corona-resistant polyimide film tape 2 is half-stacked respectively; One-sided reinforcement of imide film with less glue mica tape 3; another layer of 0.025mm thick domestic corona-resistant polyimide film tape 2 is half-stacked; Mica tape 3 with less glue reinforced by imide film on one side; then two coils covered with insulation are superimposed together, and a layer of 0.05mm thick activated polytetrafluoroethylene film tape is half-folded on the outside 4. The insulation thickness is 0.74mm.

[0017] figure 1 , figure 2 middle:

[0018] a, b are the thickness and width of copper flat wire respectively;

[0019] a+0.54 is the thickness of a copper flat wire wrapped with ground insulation;

[0020] b+0.54 is the width of a copper flat wire after wrapping the straight part of the coil with ground insulation;

[0021] 2(a+0.54)+0.2 is the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com