Low-viscosity neutral organic silicone and application thereof

A silicone, low-viscosity technology, applied in adhesives, polymer adhesive additives, film/sheet adhesives, etc., can solve the problems of easy tearing and insufficient flexibility of the covering film, and achieve resistance to cold and heat The effect of good change, easy to spray, good tear resistance and bond strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

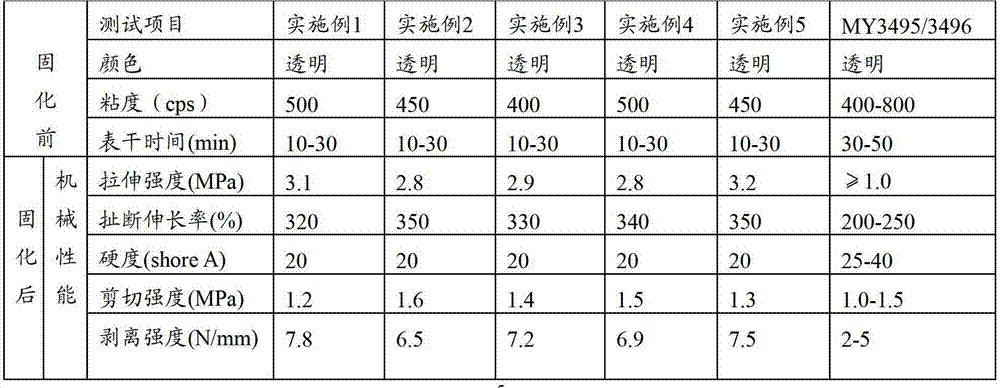

Examples

Embodiment 1

[0023] Accurately weigh the following raw materials, 100 parts of 1000mPa.s hydroxyl-terminated polydimethylsiloxane, 20 parts of 200mPa.s dimethyl silicone oil, 6 parts of vinyltriisopropoxysilane, (tetramethylguanidine Base) 1 part of propyltrimethoxysilane, 7 parts of film strengthening agent (80 parts of n-heptane, 20 parts of MQ silicone resin (molecular weight 6000), mix at room temperature for 2 hours until uniform), add the above components in sequence In the mixing mixer, vacuumize to -0.1MPa, mix for 1 hour until uniform, N 2 Seal the package and place it for use.

Embodiment 2

[0025] Accurately weigh the following raw materials, 100 parts of 1500mPa.s hydroxyl-terminated polydimethylsiloxane, 20 parts of 100mPa.s dimethyl silicone oil, 6 parts of methyltriisopropoxysilane, (tetramethylguanidine Base) 1 part of propyltrimethoxysilane, 5 parts of film enhancer (60 parts of n-heptane, 20 parts of D20 solvent oil, 20 parts of MQ silicone resin (molecular weight 3000), mix at room temperature for 2 hours until uniform), Put the above components into the mixing mixer in turn, vacuum to -0.1MPa, mix for 1.5 hours until uniform, N 2 Seal the package and place it for use.

Embodiment 3

[0027] Accurately weigh the following raw materials, 100 parts of 6000mPa.s hydroxyl-terminated polydimethylsiloxane, 50 parts of 50mPa.s dimethyl silicone oil, 6 parts of vinyltriisopropoxysilane, (tetramethylguanidine Base) 2 parts of propyltrimethoxysilane, 5 parts of film strengthening agent (60 parts of n-heptane, 20 parts of D40 solvent oil, 20 parts of MQ silicone resin (molecular weight 3000), mix at room temperature for 2 hours until uniform), Put the above components into the mixing mixer in turn, vacuum to -0.1MPa, mix for 2 hours until uniform, N 2 Seal the package and place it for use.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| peel strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com