Corona-resistant and high-frequency-impulse-resistant high-breathability little-resin mica tape suitable for variable-frequency high-voltage motors and preparation method thereof

A technology of less rubber mica tape and high-frequency pulses, which is applied in mica, electrical components, chemical instruments and methods, etc., can solve the problem that the rubber mica tape's corona resistance, high-frequency pulse resistance and heat resistance cannot meet the requirements of variable frequency motors. Voltage and insulation life requirements and other issues, to achieve the effect of high initial partial discharge voltage, excellent heat resistance, and long electrothermal aging life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

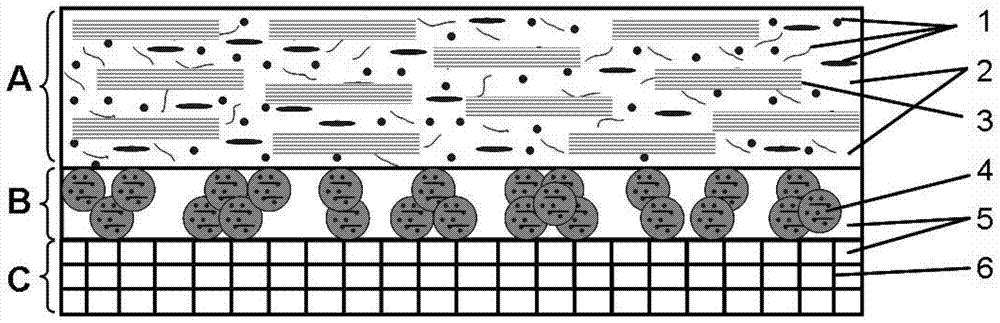

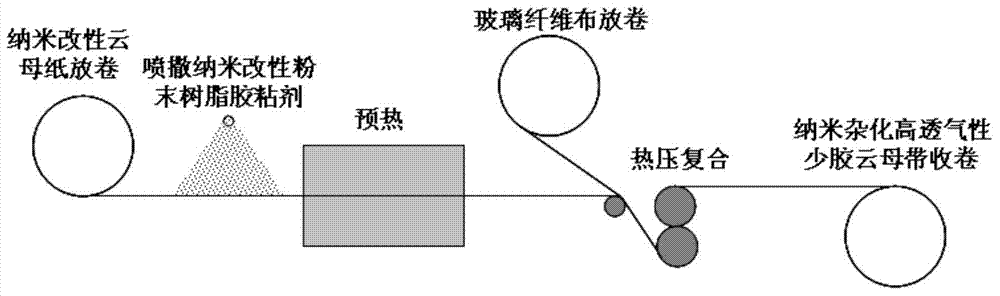

[0043] This embodiment provides a nano-hybrid mica tape with high air permeability and less rubber, and its preparation process is as follows:

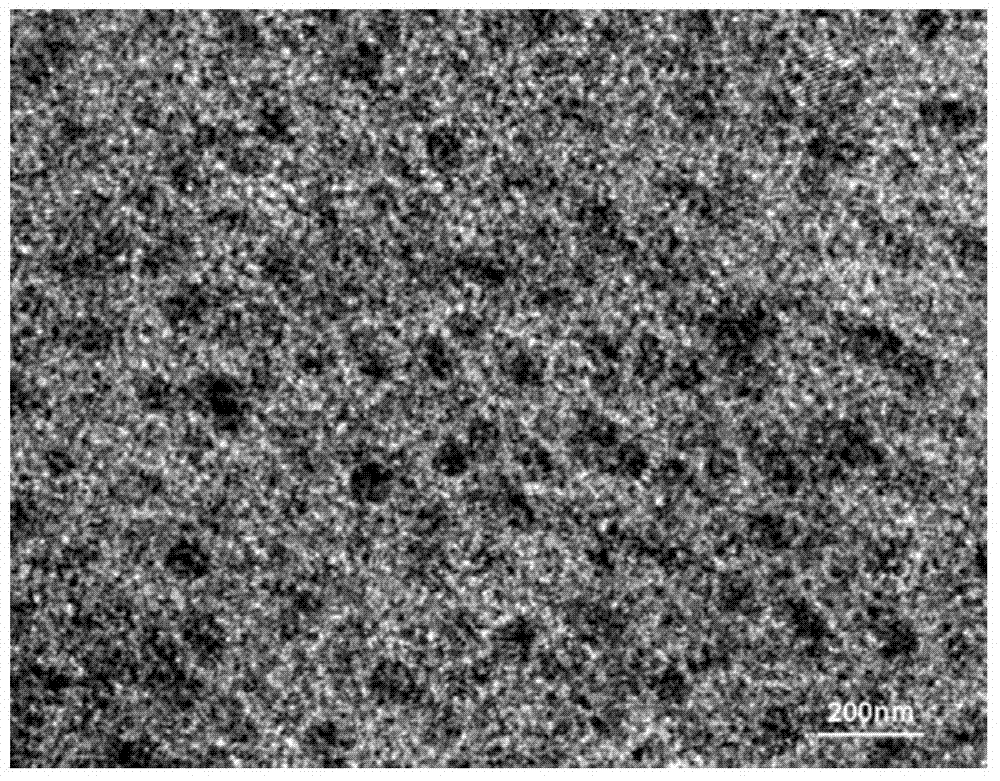

[0044] (1) Preparation of nano-modified mica paper: In the muscovite flakes prepared by the water flushing method, add an aqueous dispersion of titanium oxide nanoparticles with a mass fraction of 5% and a particle size of about 200 nm; the mass fraction is 20 %, an aqueous dispersion of titanium oxide nanowires with a diameter of about 50 nanometers and a length of about 30 microns; an aqueous dispersion of boron nitride nanosheets with a mass fraction of 10%, a thickness of about 50 nanometers, and a diameter of about 10 microns After fully stirring evenly, it is copied on a mica paper machine to form a unit area of 160g / m 2 Nano-modified mica paper, the air permeability of the nano-modified mica paper is 285s / 100mL, the thickness is 0.098mm, and the nano-material content is 56g / m 2 .

[0045] (2) Preparation of nano-modified po...

Embodiment 2

[0049] This embodiment provides a nano-hybrid mica tape with high air permeability and less rubber, and its preparation process is as follows:

[0050] (1) Preparation of nano-modified mica paper: Add an ethanol dispersion of silicon oxide nanowires with a mass fraction of 20%, a diameter of about 50 nanometers, and a length of about 30 microns to the muscovite flakes prepared by the water flushing method The mass fraction is 10%, the thickness is about 50 nanometers, and the ethanol dispersion liquid of boron nitride nanosheets with a diameter of about 10 microns, after fully stirring, is copied on a mica paper machine to form a unit area gram weight of 160g / m 2 Nano-modified mica paper, the air permeability of the mica paper is 292s / 100mL, the thickness is 0.098mm, and the nanomaterial content is 48g / m 2 .

[0051] (2) Preparation of nano-modified powder resin adhesive: 300g of SiO with a particle size of about 120nm 2 Nanoparticles and 700g of epoxyimide resin particles w...

Embodiment 3

[0055] This embodiment provides a nano-hybrid mica tape with high air permeability and less rubber, and its preparation process is as follows:

[0056] (1) Preparation of nano-modified mica paper: Add an ethanol dispersion of silicon oxide nanoparticles with a mass fraction of 5% and a particle size of about 100 nm to the muscovite flakes prepared by the water flushing method; the mass fraction is 20 %, an ethanol dispersion of titanium oxide nanowires with a diameter of about 50 nanometers and a length of about 30 microns; a mass fraction of 15%, a thickness of about 100 nanometers, and an ethanol dispersion of boron nitride nanosheets with a diameter of about 30 microns , and fully stirred evenly, copied on the mica paper machine to form a unit area of 180g / m 2 Nano-modified mica paper, the air permeability of the mica paper is 245s / 100mL, the thickness is 0.112mm, and the nanomaterial content is 72g / m 2 .

[0057] (2) Preparation of nano-modified powder resin adhesive: ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Melting temperature | aaaaa | aaaaa |

| Weight per unit area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com