Method for inhibiting charge accumulation on polyimide insulation film

A technology of polyimide film and insulating film is applied in the field of suppressing the accumulation of surface charge of polyimide insulating film, and achieves the effects of simple method, improved corona resistance performance, and huge economic and social benefits.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

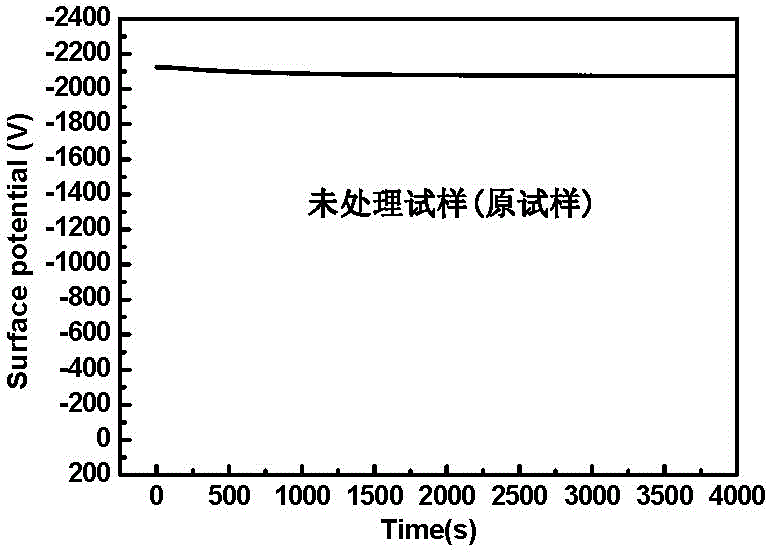

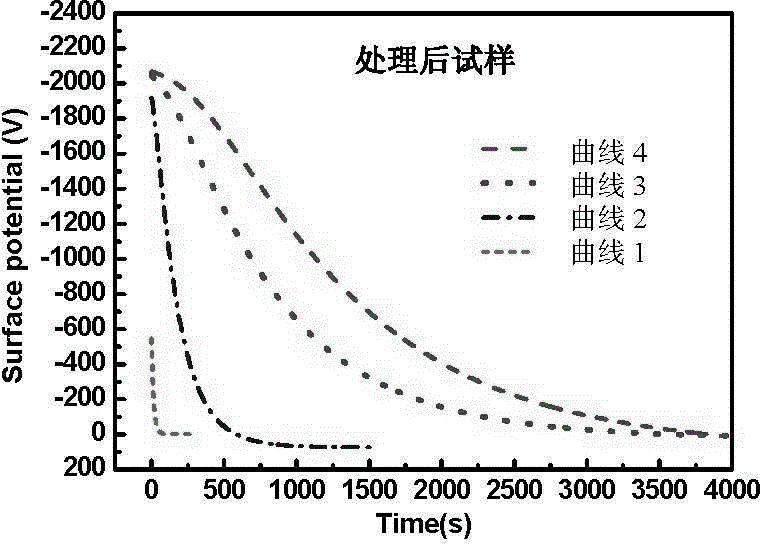

Image

Examples

Embodiment 1

[0013] In the specific implementation of the present invention, the following method is given. In a closed reaction chamber, the polyimide insulating film material is subjected to gas phase oxyfluoride fluorination treatment by first putting the polyimide insulating film into the reaction In the chamber, evacuate, and then pass a mixed gas consisting of 7.5% fluorine gas, 2.5% oxygen gas and 90% nitrogen gas into the reaction chamber by volume. The surface layer of the polyimide film is subjected to gas-phase oxygen fluorine under the mixed gas The fluorination reaction is 2-5 min, and the reaction temperature is 50-100° C.; the pressure of the mixed gas introduced is 0.05-0.15 MPa.

Embodiment 2

[0015] In the specific implementation of the present invention, it can also be given by the following method. In a closed reaction chamber, the polyimide insulating film material is subjected to gas phase oxyfluoride fluorination treatment by first putting the polyimide insulating film into The reaction chamber is evacuated, and then a mixed gas consisting of 5% fluorine gas, 1% oxygen gas and 94% nitrogen gas is passed into the reaction chamber by volume. The surface layer of the polyimide film is subjected to gas-phase oxygen under the mixed gas. The fluorine fluorination reaction was conducted for 2 minutes, and the reaction temperature was 55° C.; the pressure of the mixed gas introduced was 0.05 MPa.

Embodiment 3

[0017] In the specific implementation of the present invention, it can also be given by the following method. In a closed reaction chamber, the polyimide insulating film material is subjected to gas phase oxyfluoride fluorination treatment by first putting the polyimide insulating film into The reaction chamber is evacuated, and then a mixed gas consisting of 7% fluorine gas, 3% oxygen gas and 90% nitrogen gas is introduced into the reaction chamber by volume. The surface layer of the polyimide film is subjected to gas-phase oxygen under the mixed gas The fluorine fluorination reaction was conducted for 3 minutes, and the reaction temperature was 70°C; the pressure of the mixed gas introduced was 0.09 MPa.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com