Solvent-free type organosilicone coating adhesive and preparation method thereof

A silicone, solvent-free technology, used in adhesives, adhesive additives, polymer adhesive additives, etc., can solve the problems of poor tear resistance, high production cost, slow curing speed, etc., and achieve shock resistance and corona resistance. Performance, simple production process, good high and low temperature resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

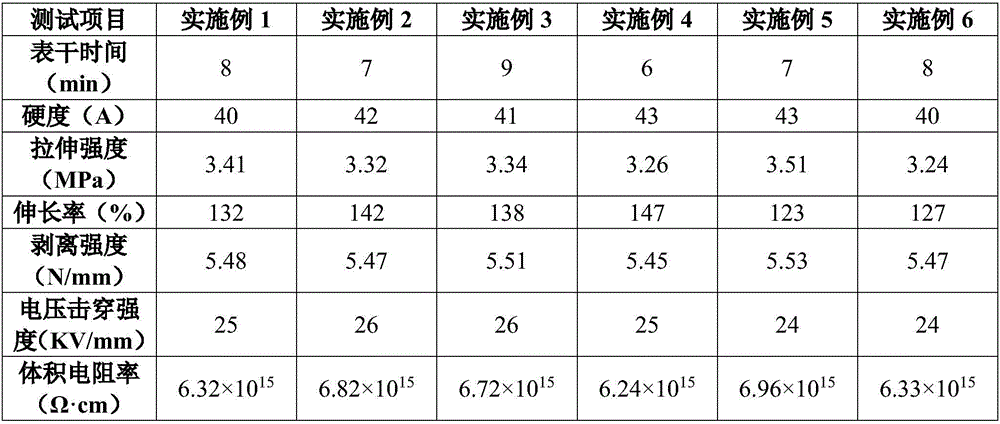

Examples

Embodiment 1

[0050] Put 70 parts by mass of α, ω-dihydroxy polydimethylsiloxane with a viscosity of 500mPa·s and 30 parts by mass of silicone resin into the reaction kettle, vacuumize and stir for 60min, then add 1 part by mass of methyl tributyl Ketoxime-based silane, 2 mass parts of vinyl tributylketoxime-based silane, 0.3 mass parts of dibutyltin diacetate and 0.5 mass parts of vinyltrimethoxysilane were stirred for 30min under vacuum to obtain solvent-free organic Silicon coating glue.

Embodiment 2

[0052] 50 parts by mass of α, ω-dihydroxypolydimethylsiloxane with a viscosity of 500mPa·s, 30 parts by mass of α with a viscosity of 1500mPa·s, ω-dihydroxypolydimethylsiloxane with 25 parts by mass The organosilicon resin is put into the reaction kettle, vacuumized and stirred for 60min, then add 3 parts by mass of vinyl tributylketoxime base silane, 0.2 parts by mass of dibutyltin dilaurate and 1 part by mass of propenyl trimethoxysilane, vacuum Stir for 30 minutes under the same conditions to obtain a solvent-free silicone coating gel.

Embodiment 3

[0054] 60 parts by mass of α with a viscosity of 500mPa·s, 20 parts by mass of α with a viscosity of 5000mPa·s, ω-dihydroxypolydimethylsiloxane with 10 parts by mass Put the silicone resin into the reaction kettle, vacuumize and stir for 60min, then add 3 parts by mass of vinyl tributylketoximosilane, 0.7 parts by mass of dioctyltin dilaurate and 0.5 parts by mass of γ-glycidyl ether oxypropyl Trimethoxysilane was stirred for 30 minutes under vacuum to obtain a solvent-free silicone coating gel.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com