Nickel-base high-temperature alloy/titanium alloy composite material for aero-engine

A nickel-based high-temperature alloy and aero-engine technology, applied in the field of composite materials, can solve problems such as easy oxidation, low heat-resistant temperature, and high heat-resistant temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

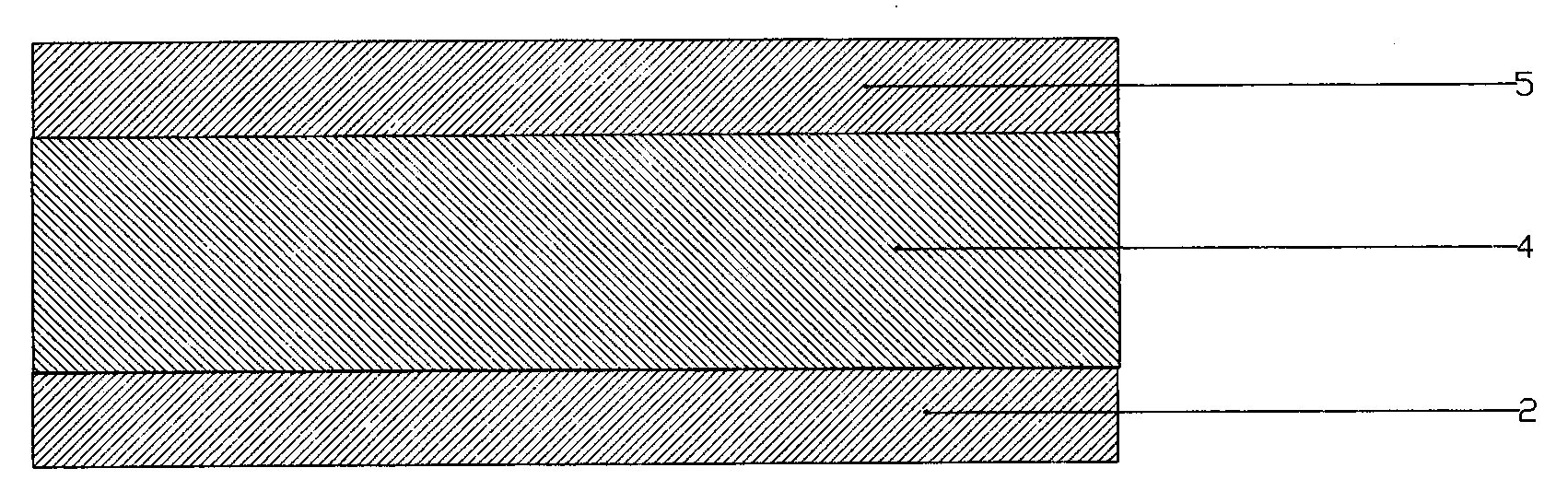

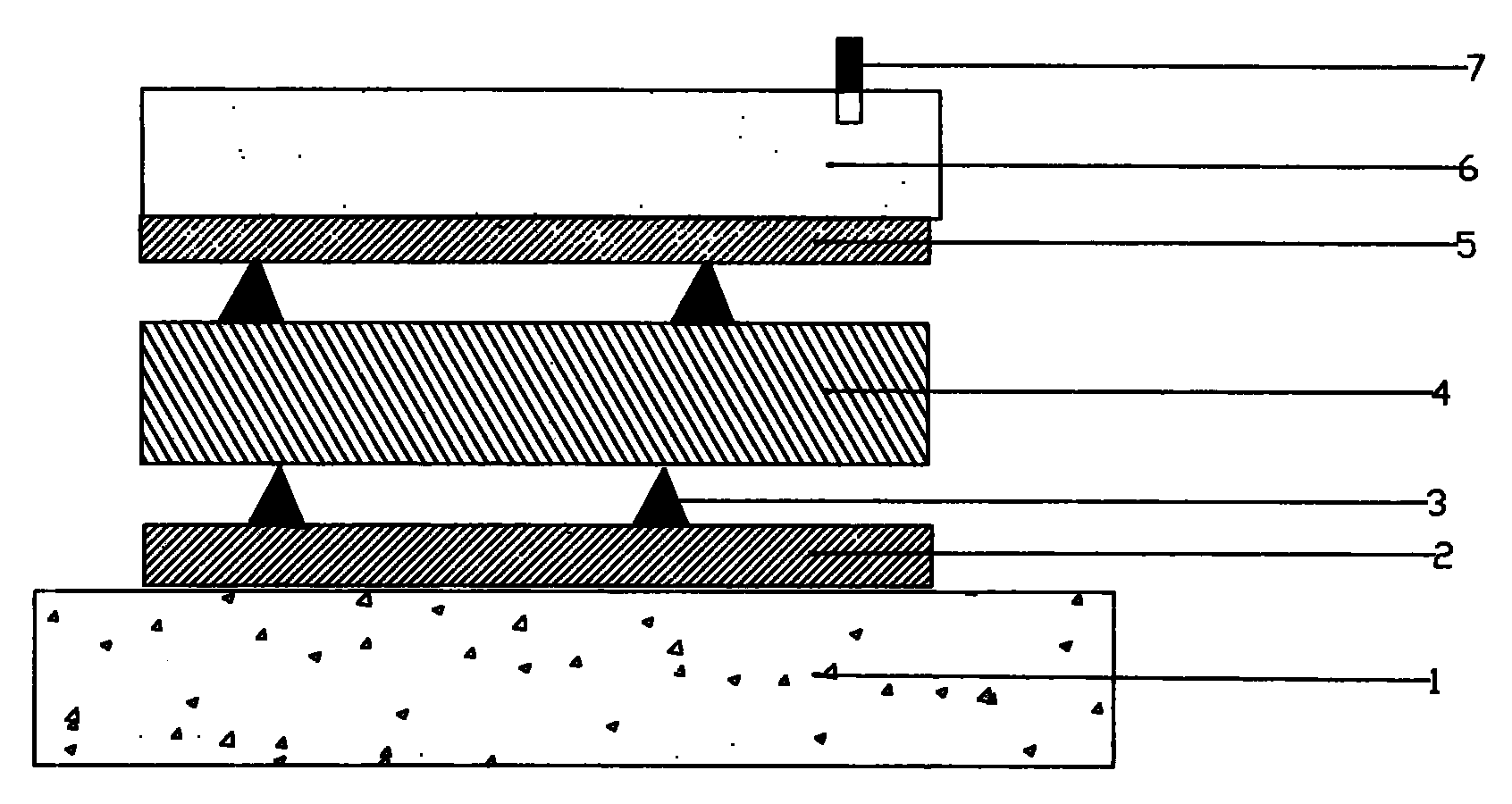

[0015] The material grade of the titanium alloy is Ti-6Al-4V, the thickness is 2mm, and its chemical composition is: aluminum: 5.5%-6.75%, vanadium: 3.5%-4.5%, and the balance is titanium. The material grade of nickel-based alloy is K4169, the thickness is 8mm, the chemical composition of K4169: aluminum: 0.5%, zirconium: 0.05%, titanium: 1.0%, manganese: 3.0%, niobium: 5.2%, chromium: 18.5%, nickel 52% , molybdenum: 3.0%, carbon: 0.05%, and the balance is iron. The charge height of the explosive is 30mm, and the gap is 5mm.

[0016] Among them, the titanium alloy Ti-6Al-4V has a series of advantages such as excellent corrosion resistance, small density, high specific strength, good toughness and weldability. The main alloying element of nickel-based alloy K4169 is nickel, which has high strength, fatigue life, fracture toughness and fatigue crack growth resistance.

[0017] Specific steps:

[0018] (1) A nickel-based superalloy / titanium alloy composite material for aeroeng...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com