Preparation method of rosinyl acrylamide polymer

A technology of rosin-based acrylamide and polymers, which is applied in the field of preparation of rosin-based acrylamide polymers, can solve problems such as high temperature resistance and poor salt resistance, achieve excellent heat resistance, solve heat resistance, and synthesize steps simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

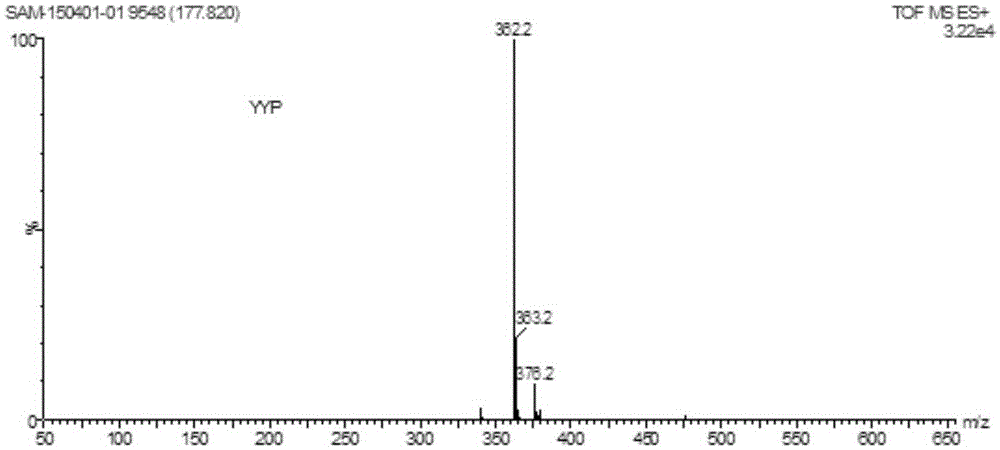

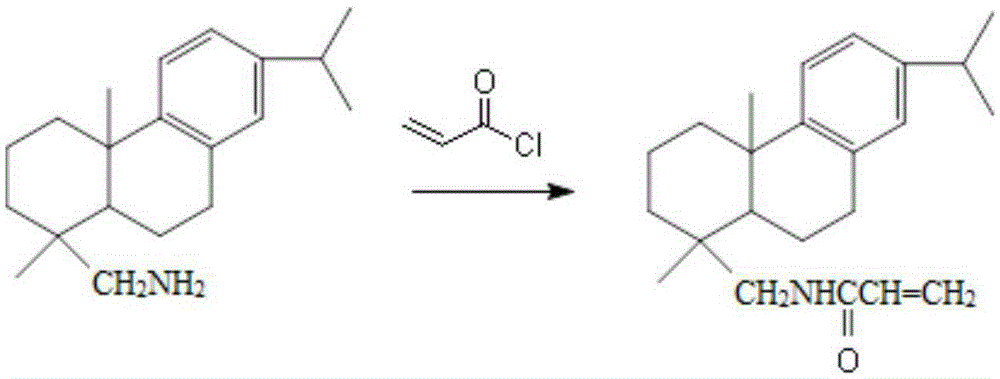

[0026] Add 15.0 g of dehydroabietylamine to a 500 ml flask equipped with a thermometer, a stirrer, and an air duct, then add 50 mL of tetrahydrofuran to dissolve, keep the reaction temperature at 10°C, and slowly add 5.0 g of propylene dropwise at a rate of 0.05 ml / min Acyl chloride, react for 3 hours after the dropwise addition, then add triethylamine to remove the HCl released in the reaction until there is no obvious HCl smoke in the bottle, filter to remove the salt precipitate, then distill the solvent under reduced pressure, add the residue to ethanol to dissolve and recrystallize, and obtain 16.8 g rosin-based acrylamide monomer.

[0027] Put 15.0g of rosin-based acrylamide monomer and 0.075g of ammonium persulfate in a 500ml flask equipped with a thermometer and a stirrer, and add 60mL of 80% ethanol to dissolve, use nitrogen protection to react at 70°C for 2.5h, after cooling A white solid was obtained by suction filtration, and dried to a constant weight to obtain 13...

Embodiment 2

[0034] Add 15.0 g of dehydroabietylamine to a 500 ml flask equipped with a thermometer, a stirrer, and an air duct, then add 60 mL of tetrahydrofuran to dissolve, keep the reaction temperature at 15°C, and slowly add 4.5 g of propylene dropwise at a rate of 0.10 ml / min Acyl chloride, react for 3 hours after the dropwise addition, then add triethylamine to remove the HCl released in the reaction until there is no obvious HCl smoke in the bottle, filter to remove the salt precipitate, then distill the solvent under reduced pressure, add the residue to ethanol to dissolve and recrystallize, and obtain 15.4 g rosin-based acrylamide monomer.

[0035] Put 15.0g of rosin-based acrylamide monomer and 0.075g of potassium persulfate in a 500ml flask equipped with a thermometer and a stirrer, and add 65mL of 80% ethanol to dissolve, use nitrogen protection to react at 75°C for 2.0h, after cooling A white solid was obtained by suction filtration, and dried to a constant weight to obtain 1...

Embodiment 3

[0038] Add 15.0 g of dehydroabietylamine to a 500 ml flask equipped with a thermometer, a stirrer, and an air duct, then add 70 mL of tetrahydrofuran to dissolve, keep the reaction temperature at 5°C, and slowly add 5.5 g of propylene dropwise at a rate of 0.15 ml / min Acyl chloride, react for 4 hours after the dropwise addition, then add triethylamine to remove the HCl released in the reaction until there is no obvious HCl smoke in the bottle, filter to remove the salt precipitate, then distill the solvent under reduced pressure, add the residue to ethanol to dissolve and recrystallize, and obtain 16.1 g rosin-based acrylamide monomer.

[0039] Put 15.0g of rosin-based acrylamide monomer and 0.085g of ammonium persulfate in a 500ml flask equipped with a thermometer and a stirrer, and add 60mL of 75% ethanol to dissolve, use nitrogen protection to react at 70°C for 2.0h, after cooling A white solid was obtained by suction filtration, and dried to a constant weight to obtain 13....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com