Mineral/ whisker reinforced polypropylene composition

A polypropylene composition and polypropylene technology, applied in the field of polypropylene, can solve the problems of insufficient strength, stiffness and heat resistance, reduced material impact strength, and limited material application, etc., to solve the problem of dimensional instability and impact strength Improve and expand the effect of the application field

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-4

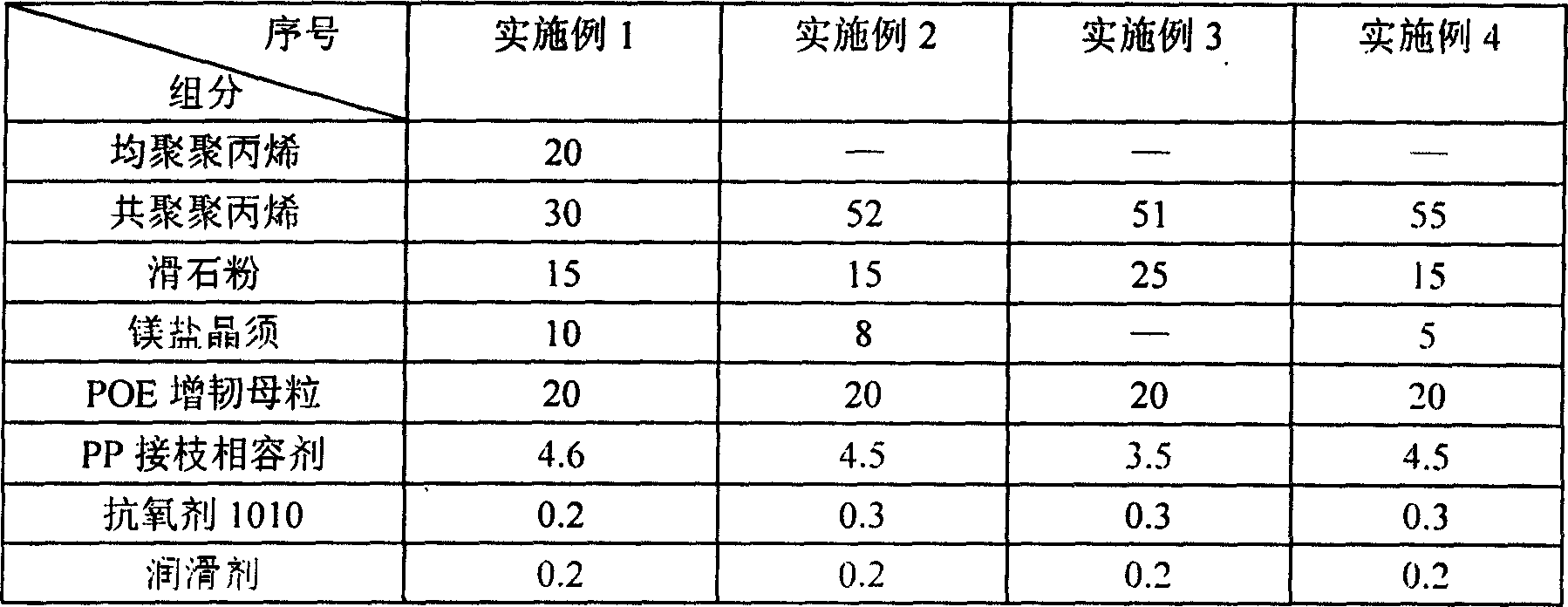

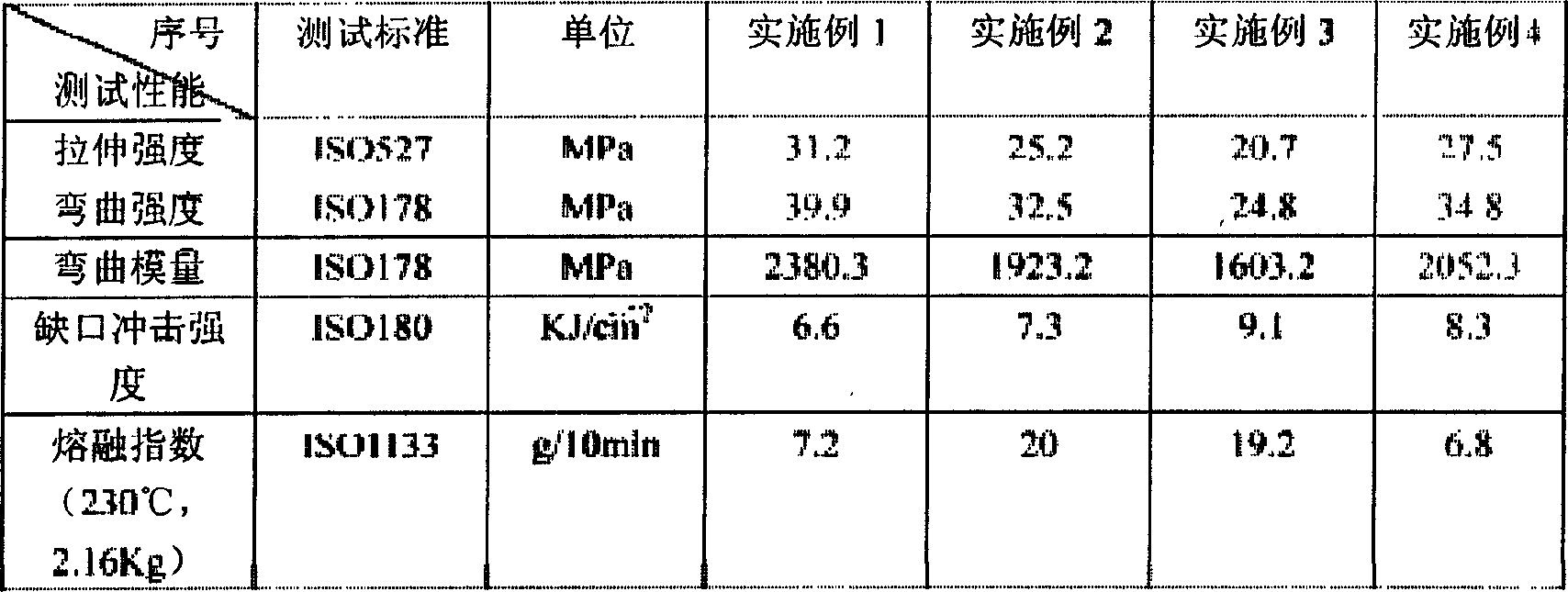

[0034] Based on the blend of copolymerized polypropylene and homopolypropylene, talcum powder / magnesium salt whisker is used as reinforcing agent, PP-g-MAH is used as compatibilizer, POE rubber masterbatch is used as toughening agent, its weight The ratio is listed in Table 1,

[0035] Table 1: Weight ratio of mineral / whisker reinforced polypropylene composition components

[0036]

[0037] The preparation method of the present invention is as follows:

[0038] (1) Surface treatment of talcum powder with KH550;

[0039] (2) the surface of the magnesium salt whisker is treated with KH-550;

[0040] (3) Put polypropylene, copolymerized polypropylene, talcum powder, POE toughening masterbatch, PP graft compatibilizer, and antioxidant 1010 together in a high mixer and mix for 3 minutes;

[0041] (4) Add whisker magnesium salt whisker and mix at low speed for 1 minute;

[0042] (5) discharge;

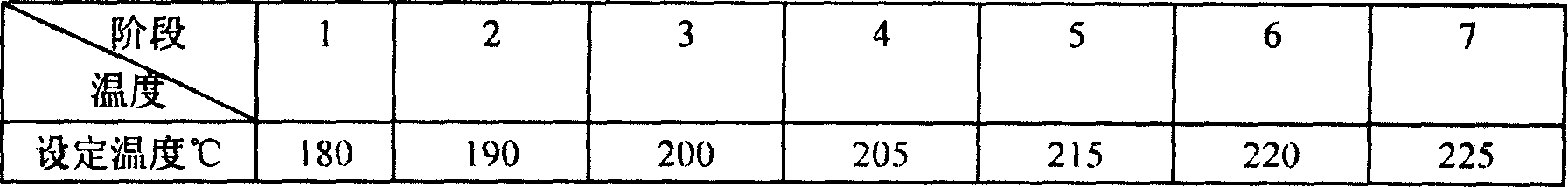

[0043] (6) The mixed raw materials are placed in a twin-screw machin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com