High-temperature-resistant and shrinkage-resistant ceramic diaphragm and manufacturing method and application thereof

A ceramic diaphragm and high-temperature-resistant technology, which is applied in the direction of electrical components, circuits, battery pack components, etc., can solve problems such as safety concerns, inappropriate lithium-ion power batteries, poor heat resistance, etc., and achieve the effect of improving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] 6 grams of polyester fiber non-woven fabric and 4 grams of polyolefin microporous membrane are combined by a wet process to form a non-woven separator-coated microporous membrane. The non-woven separator-coated microporous membrane is used in new Production of lithium-ion power batteries. The new lithium-ion power battery to be produced is tested.

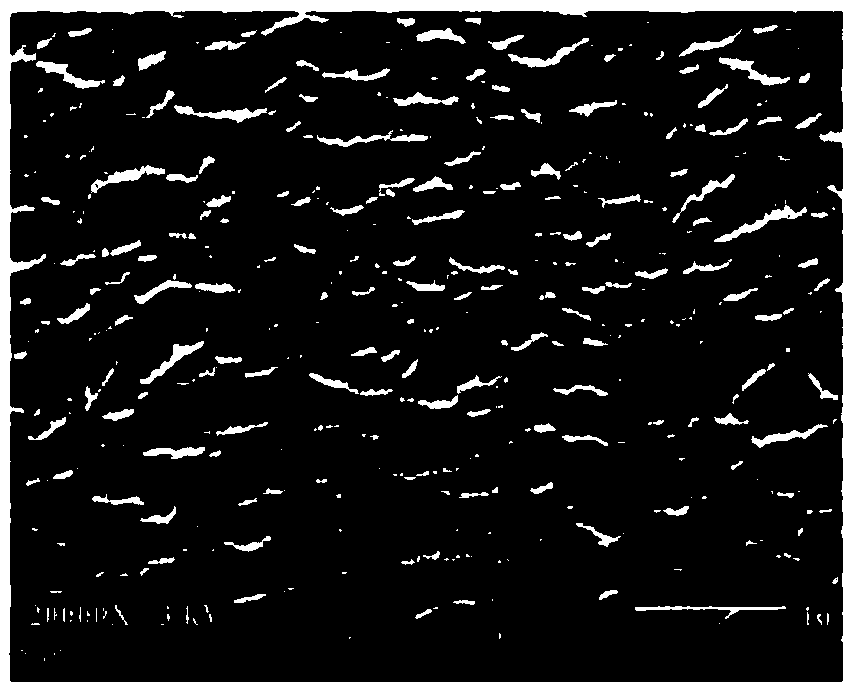

[0019] The test results are: the ionic conductivity is higher than 10-3S / cm, the pore size is 0.4μm, the film thickness is 15μm, the air permeability of the film is 100s / 100cc: 85, the shrinkage rate at 200°C is less than 1%, and the shrinkage rate at 180°C is 0. Result reference figure 1 .

Embodiment 2

[0021] Using 6 grams, 10 grams, 20 grams of polyester fiber non-woven fabrics and 4 grams, 20 grams, 15 grams of polyolefin microporous membranes are combined by a wet process to form a non-woven diaphragm-coated microporous membrane. The non-woven diaphragm laminated microporous membrane is used in the production of new lithium-ion power batteries. The new lithium-ion power battery to be produced is tested.

[0022] The test results are: the ionic conductivity is higher than 10-3S / cm, the pore size is 0.6μm, the film thickness is 60μm, the air permeability of the film is 90s / 100cc: 85, the shrinkage rate at 200°C is less than 1%, and the shrinkage rate at 180°C is 0. Result reference figure 1 .

Embodiment 3

[0024] 20 grams of polyester fiber non-woven fabric and 15 grams of polyolefin microporous membrane are combined by papermaking wet process to form a non-woven diaphragm-coated microporous film. The non-woven diaphragm-coated microporous film is used in Production of new lithium-ion power batteries. The new lithium-ion power battery to be produced is tested.

[0025] The test results are: the ionic conductivity is higher than 10-3S / cm, the pore size is 0.7μm, the film thickness is 45μm, the air permeability of the film is 80s / 100cc: 85, the shrinkage rate at 200°C is less than 1%, and the shrinkage rate at 180°C is 0. Result reference figure 1 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical conductivity | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com