Method for preparing lithium battery power diaphragm

A lithium battery and power technology, which is applied to battery components, circuits, electrical components, etc., can solve the problems of hidden safety concerns, easy shrinkage of the diaphragm, and low porosity, and achieve the effect of improving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

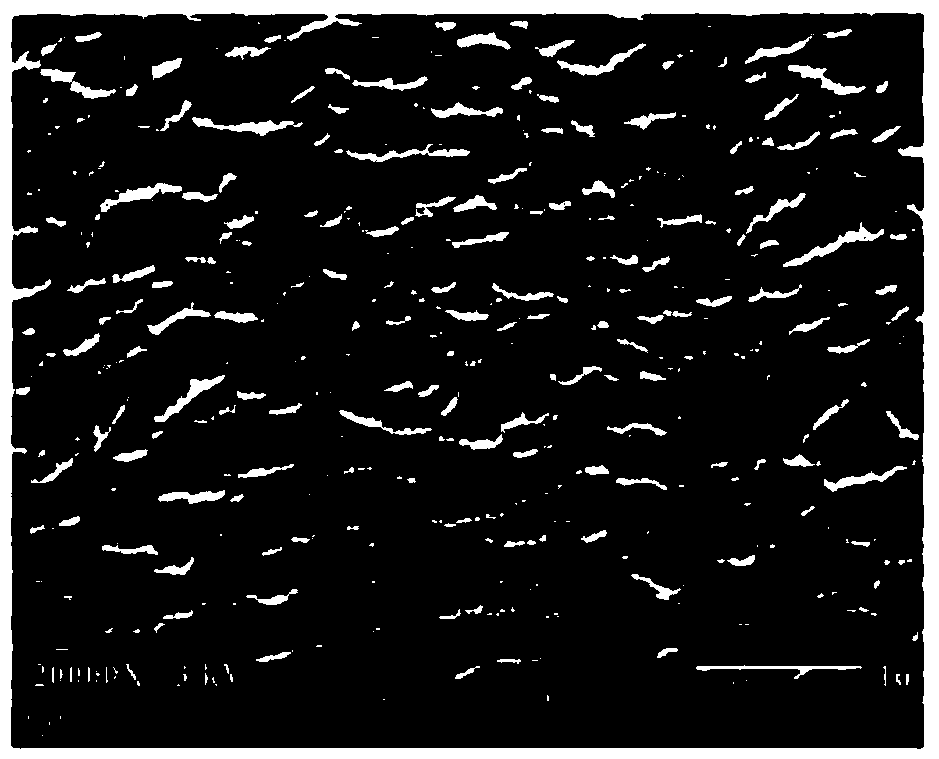

Image

Examples

Embodiment 1

[0028] A preparation method of a lithium battery power diaphragm, comprising the following steps:

[0029] 1) Preparation of synthetic cotton film: The synthetic cotton film contains the following components: 0.1D staple fiber 40~55%, ether 25~35%, acetone 3~5%, glacial acetic acid 4~7%, methylcellulose 0.3~0.5% %, ethanol 1~2%, oil 1~2%, toluene 1~2%, resin 2~3%, the balance is diluent;

[0030] 2) Preparation of polyolefin microporous film: using polyolefin resin, nucleating agent and solvent as raw materials, and using the mass ratio as polyolefin resin: nucleating agent: solvent = 1000-2000: 20-50: 2000-3000 to prepare a polyolefin film. Olefin solution; then extruded into polyolefin solution and gel sheet, stretched, film-forming solvent to remove surface impurities, dried, heat-treated and shaped to obtain polyolefin microporous membrane;

[0031] 3) Synthetic ceramic diaphragm: One or more of the synthetic cotton film and the polyolefin microporous film with a specific...

Embodiment 2

[0033] Using 6 grams of synthetic cotton film cloth and 4 grams of polyolefin microporous film to composite a ceramic diaphragm by wet process, the ceramic diaphragm is used in the production of new lithium-ion power batteries. To test the new lithium-ion power battery produced.

[0034] The test results are: the ionic conductivity is higher than 10-3 S / cm, the pore size is 195nm, the film thickness is 15μm, the film air permeability is 130s / 100ml, the shrinkage rate is less than 1% at 200°C, and the shrinkage rate is 0 at 180°C.

Embodiment 3

[0036] Using 6 grams, 10 grams, 20 grams of synthetic cotton film cloth and 4 grams, 20 grams, 15 grams of polyolefin microporous membranes are composited by wet process to make ceramic diaphragms, which are used in new lithium-ion power batteries. Production. To test the new lithium-ion power battery produced.

[0037] The test results are: the ionic conductivity is higher than 10-3 S / cm, the pore size is 130nm, the film thickness is 60μm, the film air permeability is 190s / 100ml, the shrinkage rate at 200°C is less than 1%, and the shrinkage rate at 180°C is 0.

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical conductivity | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com