Double-rotation four-cycle piston type double-shaft internal combustion engine, pressure flow driver and pump

A rotary piston and piston type technology, which is applied to fluid power machinery and pumps, rotary pressure fluid power machinery and rotary piston pressure pumps, belongs to the field of internal combustion engines, and can solve the problem of different time, speed, power, thrust, and unsystematic supporting technologies Solve and increase the problems of abrupt speed changes, etc., to achieve the effect of wide power range, high power-to-weight ratio, and reduced heat loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

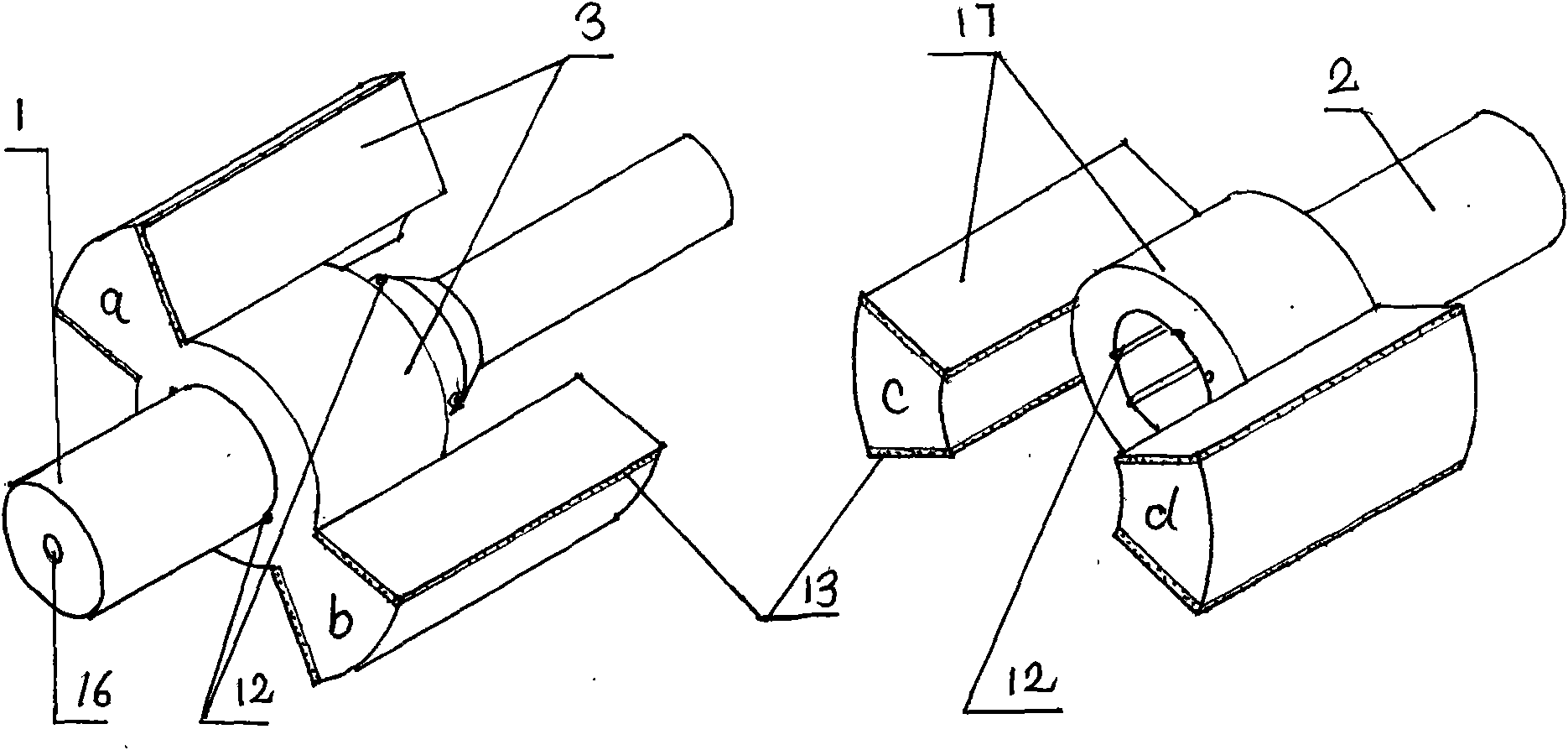

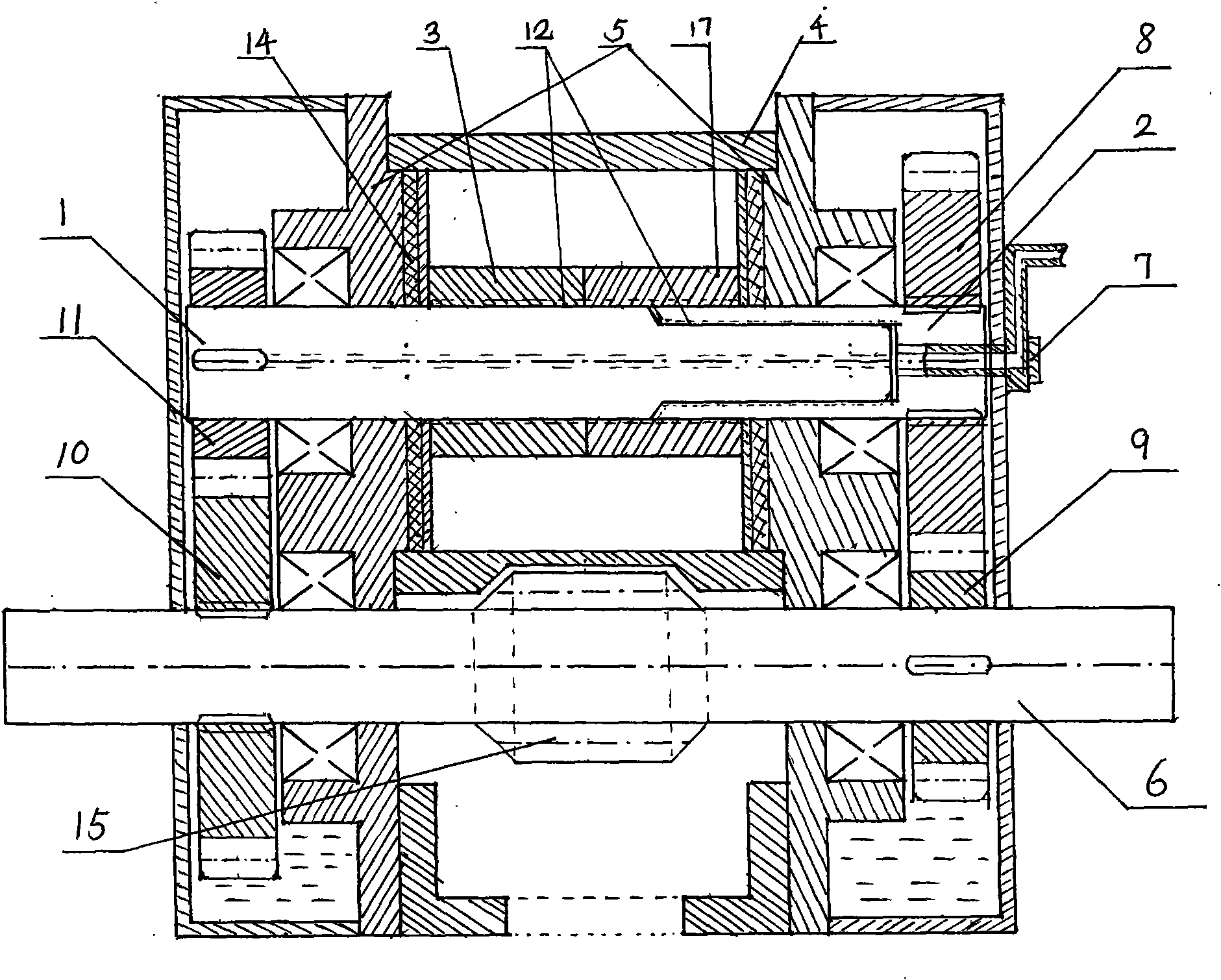

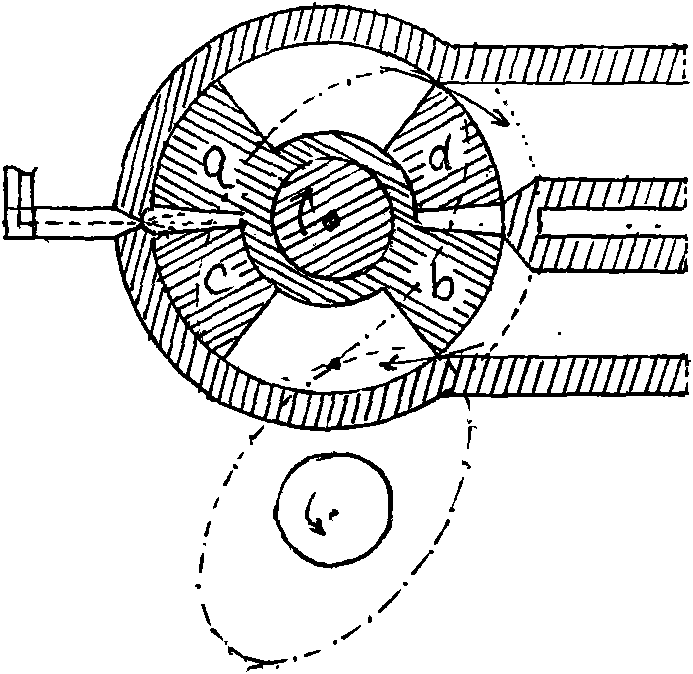

[0032] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. figure 1 , figure 2 Middle 3 and 17 are schematic diagrams of the structure of the integral rotary piston, and its integral structure ensures the needs of working under high speed and high torque. The crankshaft 1 is a stepped shaft and the sleeve shaft 2 has an equal-strength structure in terms of transmission mechanical strength, which ensures the control and output strength requirements of the two pairs of rotary pistons. The gear shafts of 15 and 6 are in the same body, which can achieve the effect of maximum transmission strength, no increase in space occupation, and convenient output matching.

[0033] figure 2 Among them, the crankshaft 1 and the sleeve shaft 2 are concentric sliding sleeve configurations, and are parallel to the control shaft, that is, the output shaft 6 . The oval gear 8 positioned and connected to the sleeve shaf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com