Resin composition with high-heat, high-glass transition temperature for printed circuit board, prepreg and coating substance

A technology of resin composition and printed circuit board, which is applied in the direction of printed circuit components, circuit substrate materials, synthetic resin layered products, etc., can solve problems such as thermal conductivity not meeting the requirements, and achieve improved service life and stability, Effects of high glass transition temperature and high thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] Get the bisphenol A type epoxy resin of 20.2 weight parts (EEW (epoxy equivalent)=186g / eq, Nanya Plastics Company, product name: NPEL-128E), the phenol-benzaldehyde type multifunctional epoxy resin of 49.5 weight parts And the tetrabromobisphenol A (TBBA) of 21.2 weight parts, after these 3 kinds of resins were reacted at 170 ℃ for 120 minutes, be cooled to 130 ℃ and add the tetrabromobisphenol A type epoxy resin (EEW=390g / eq, South Asia Plastics Company, product name: NPEB-400) and 2 weight parts of four-functional epoxy resin (South Asia Plastics Company, product name: NPPN-431), after mixing evenly, make brominated epoxy resin EP- 1.

[0043] Brominated epoxy resin EP-1 is dissolved in 20wt% acetone again, is configured into the solution that contains 80wt% brominated epoxy resin EP-1, and the epoxy resin EP-1 that gets like this has EEW (epoxy equivalent)= 378, weight average molecular weight=3366, bromine content=15.8wt%.

[0044] With 100 parts by weight of b...

Embodiment 2

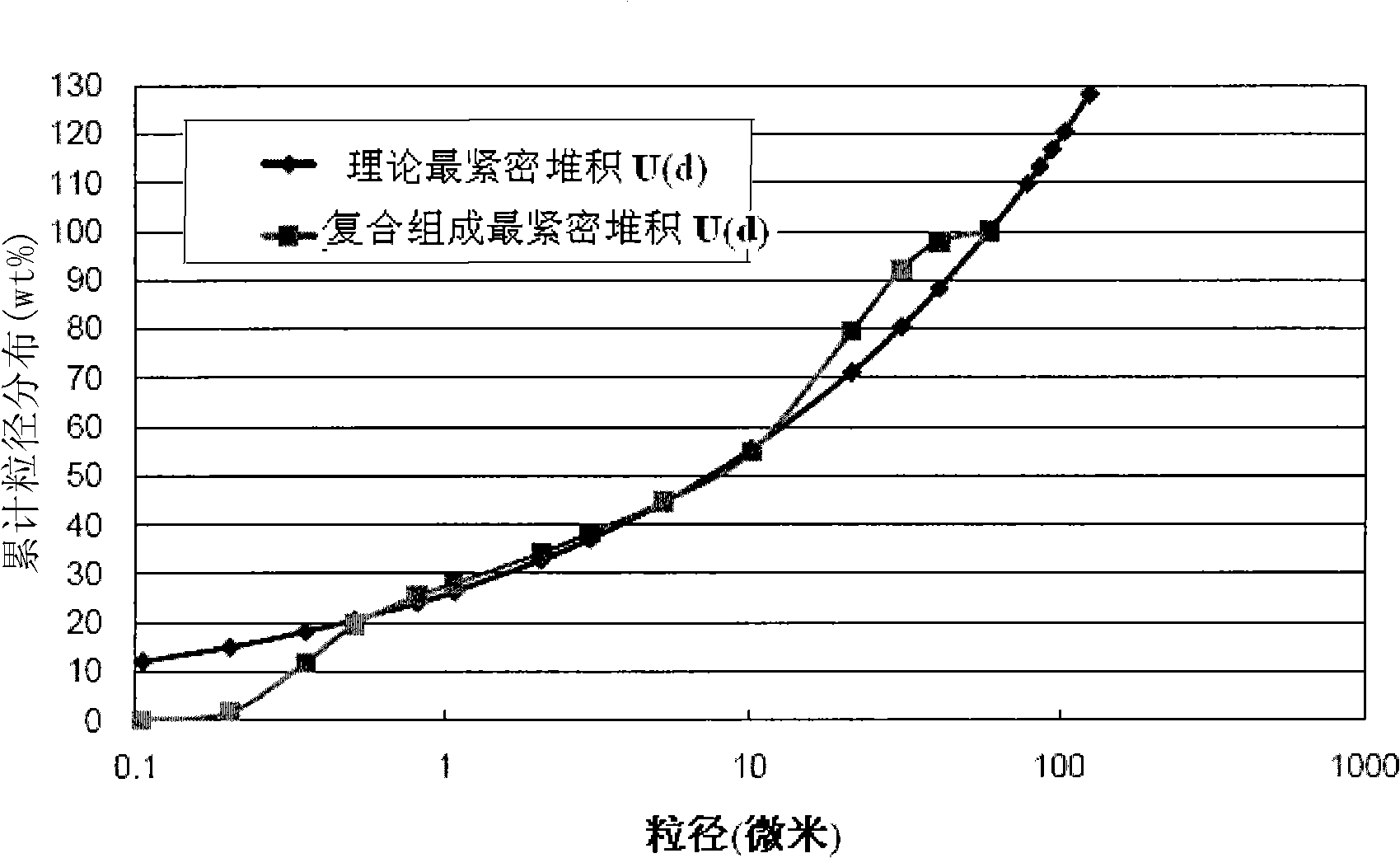

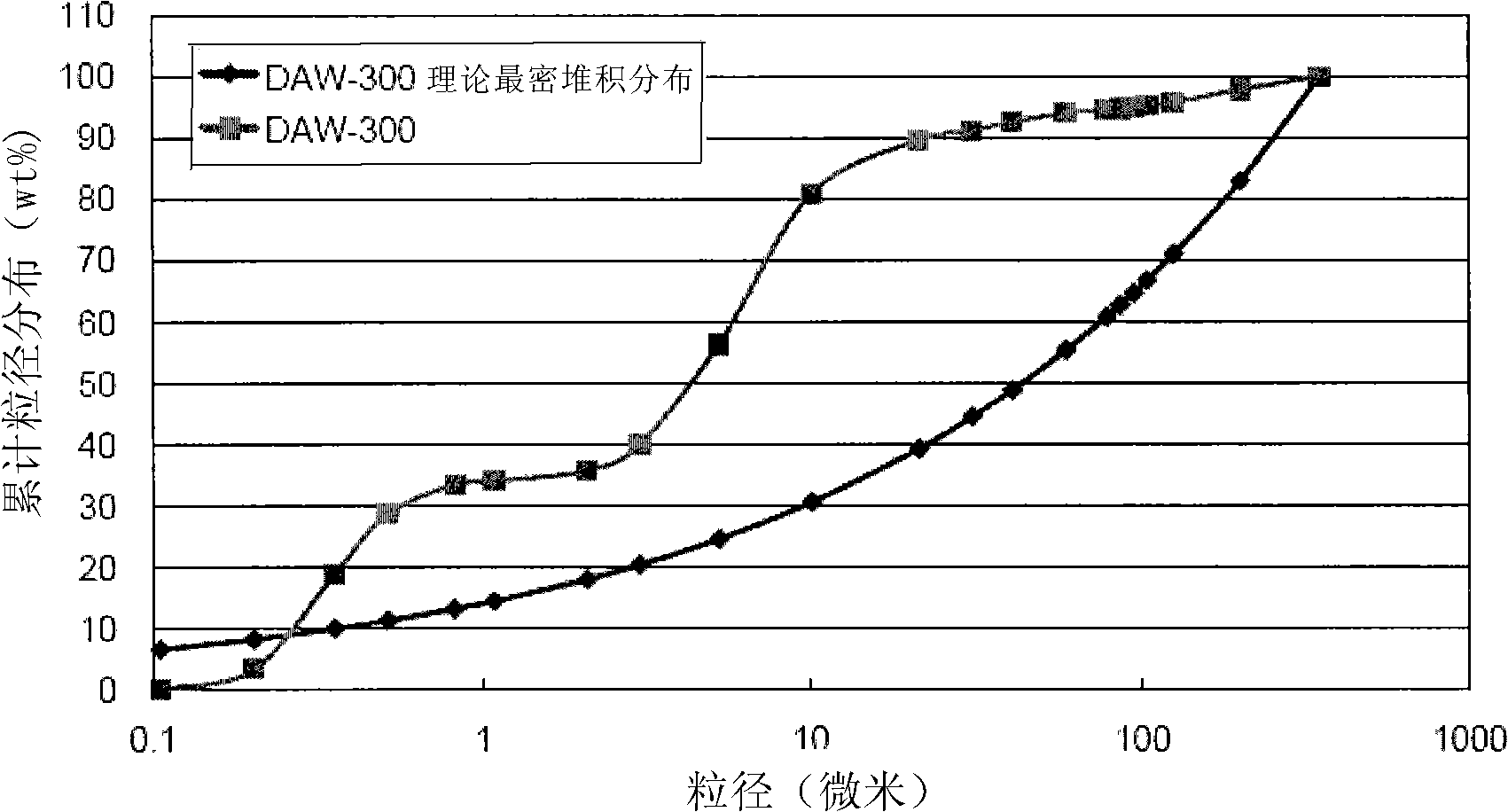

[0049] The resin solution formula of embodiment 1 is changed into the high thermal conductivity powder of blending 400 weight parts, utilizes the Horsfield model to obtain the closest packing model of high thermal conductivity powder, and its specific proportion is the spherical alumina of 72 weight parts (average particle size Diameter D 50 =5μm), 8 parts by weight of spherical alumina (average particle diameter D 50 =0.5μm) and 320 parts by weight of boron nitride (average particle size D 50 =5.5μm), where the actual packing curve of alumina powder is compared with the theoretical closest packing curve as figure 1 .

[0050] The physical properties of the prepared copper foil substrate were tested, and the results are shown in Table 1.

Embodiment 3

[0052] The formula of the resin solution is the same as that in Example 2, but the solid content of the resin solution is adjusted to 75wt%, and then coated on a 35 μm copper foil to form an adhesive-backed copper foil (RCC) with a coating thickness of 100 μm, and then laminated on the resin surface The 35 μm copper foil was pressed, and the pressing conditions were the same as in Example 1. Finally, the physical properties of the copper foil substrate were tested after the copper foil was etched. The results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| epoxy equivalent | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com