Halogen-free non-phosphorization flame-retardant epoxy resin composition and preparation method thereof

A technology of epoxy resin and liquid epoxy resin, applied in non-halogen non-phosphating flame retardant epoxy resin composition and its preparation, epoxy resin composition field, can solve the problem that phosphorus-based flame retardant is prohibited to use, electronic Product reliability decline, toxic gas and other problems, to achieve good electrical performance, strong environmental protection, improve the effect of flame retardant

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

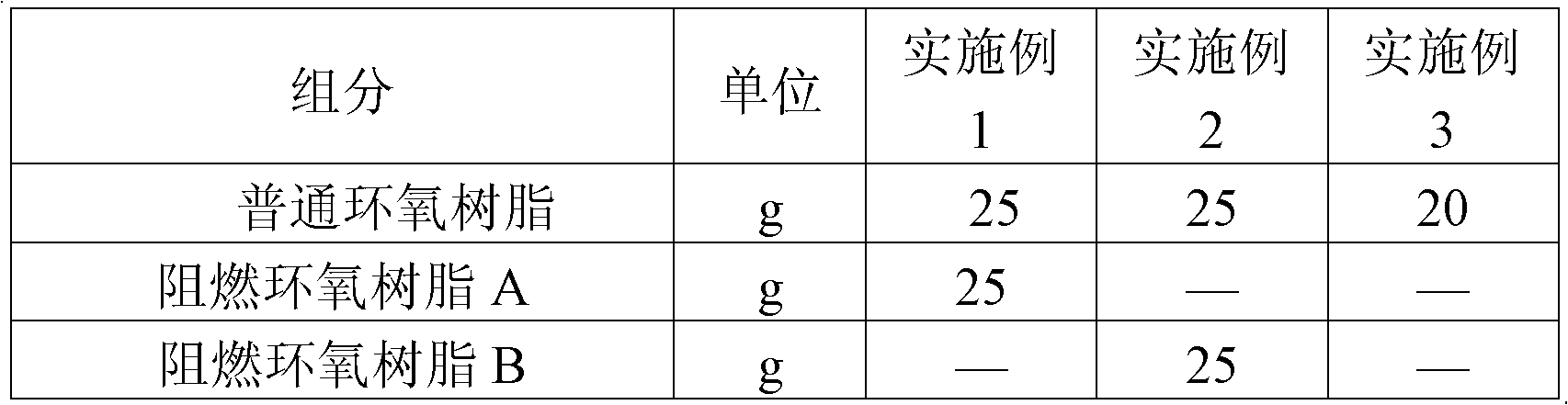

[0048] A non-halogen non-phosphorized flame-retardant epoxy resin composition, which consists of epoxy resin, flame-retardant epoxy resin A, curing agent, curing accelerator, and flame-retardant synergist. See Table 1.

[0049] The preparation method is as follows: epoxy resin, flame-retardant epoxy resin A, curing agent, curing accelerator, flame-retardant synergist and other components are pre-mixed according to the mass ratio, the pre-mixing time is 5-20 min, and the rotation speed 500~1000r / min; then, melt mixing extrusion melt mixing extrusion, extrusion temperature 70~150℃, extruder speed 1500~3000r / min, feeding speed 900~2400r / min, then pulverize ( The rotation speed is 1500-2600r / min, and the feeding speed is 600-2400r / min), which can be used for the flame-retardant epoxy resin composition.

[0050] Among them, the synthesis method of flame-retardant epoxy resin A is:

[0051] Add 560g NPEL127E (Taiwan Nanya, bisphenol A epoxy resin, epoxy value 0.5435~0.5682eq / 100g) in a 1L...

Embodiment 2

[0056] A non-halogen, non-phosphorized flame-retardant epoxy resin composition, which consists of epoxy resin, flame-retardant epoxy resin B, curing agent, curing accelerator, and flame-retardant synergist. See Table 1.

[0057] The preparation method is as follows: epoxy resin, flame-retardant epoxy resin B, curing agent, curing accelerator, flame-retardant synergist and other components are pre-mixed according to the mass ratio, the pre-mixing time is 5-20min, and the rotation speed 500~1000r / min; then, melt mixing and extrusion, where the extrusion temperature is 70~150℃, the extruder speed is 1500~3000r / min, the feeding speed is 900~2400r / min, and then it is crushed at 1500~2600r / min, the feeding speed is 600-2400r / min, that is, the flame-retardant epoxy resin composition.

[0058] Among them, the synthesis method of flame-retardant epoxy resin B is:

[0059] Add 520g NPEL127E (Taiwan Nanya, Bisphenol A epoxy resin, epoxy value 0.5435~0.5682eq / 100g) in a 1L four-necked flask eq...

Embodiment 3

[0065] A non-halogen non-phosphorized flame-retardant epoxy resin composition, which consists of epoxy resin, flame-retardant epoxy resin C, curing agent, curing accelerator, and flame-retardant synergist. See Table 1.

[0066] The preparation method is as follows: epoxy resin, flame-retardant epoxy resin C, curing agent, curing accelerator, flame-retardant synergist and other components are pre-mixed according to the mass ratio, and the pre-mixing time is 5-20 min, and the rotation speed 500~1000r / min; then, melt mixing and extrusion, where the extrusion temperature is 70~150℃, the extruder speed is 1500~3000r / min, the feeding speed is 900~2400r / min, and then it is crushed at 1500~2600r / min, the feeding speed is 600-2400r / min, that is, the flame-retardant epoxy resin composition.

[0067] Among them, the synthesis method of flame-retardant epoxy resin C is:

[0068] Add 522g NPEL127E (Taiwan Nanya, bisphenol A epoxy resin, epoxy value 0.5435~0.5682eq / 100g) in a 1L four-necked flas...

PUM

| Property | Measurement | Unit |

|---|---|---|

| epoxy value | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| epoxy value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com