Polyimide/polyacrylonitrile blended fiber and preparation method thereof

A technology of blending fiber and polyacrylonitrile, which is applied in the direction of wet spinning, conjugated synthetic polymer rayon, heat treatment of rayon, etc., can solve the problems not involved in the blending of polyimide fiber materials, and achieve High heat resistance, expanded application field, and improved fracture strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

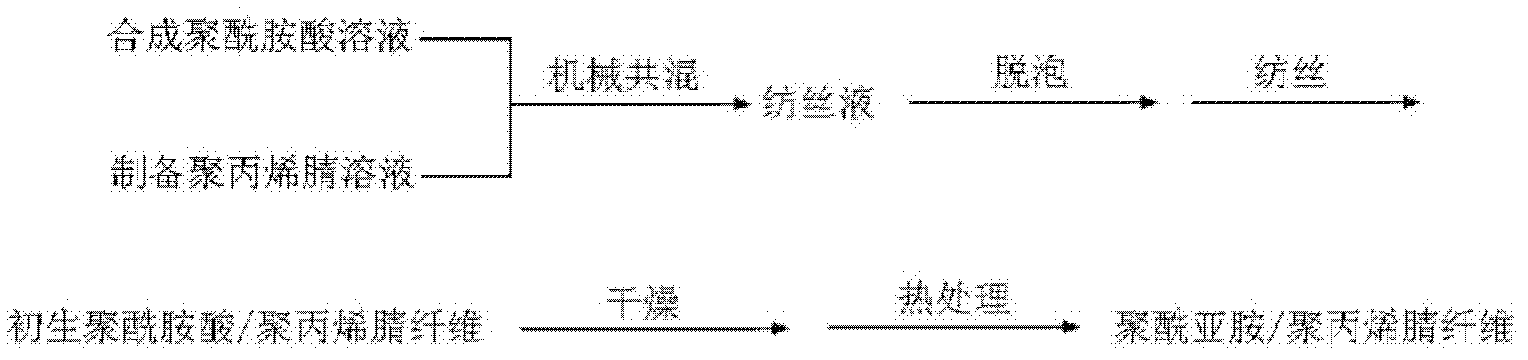

Method used

Image

Examples

Embodiment 1

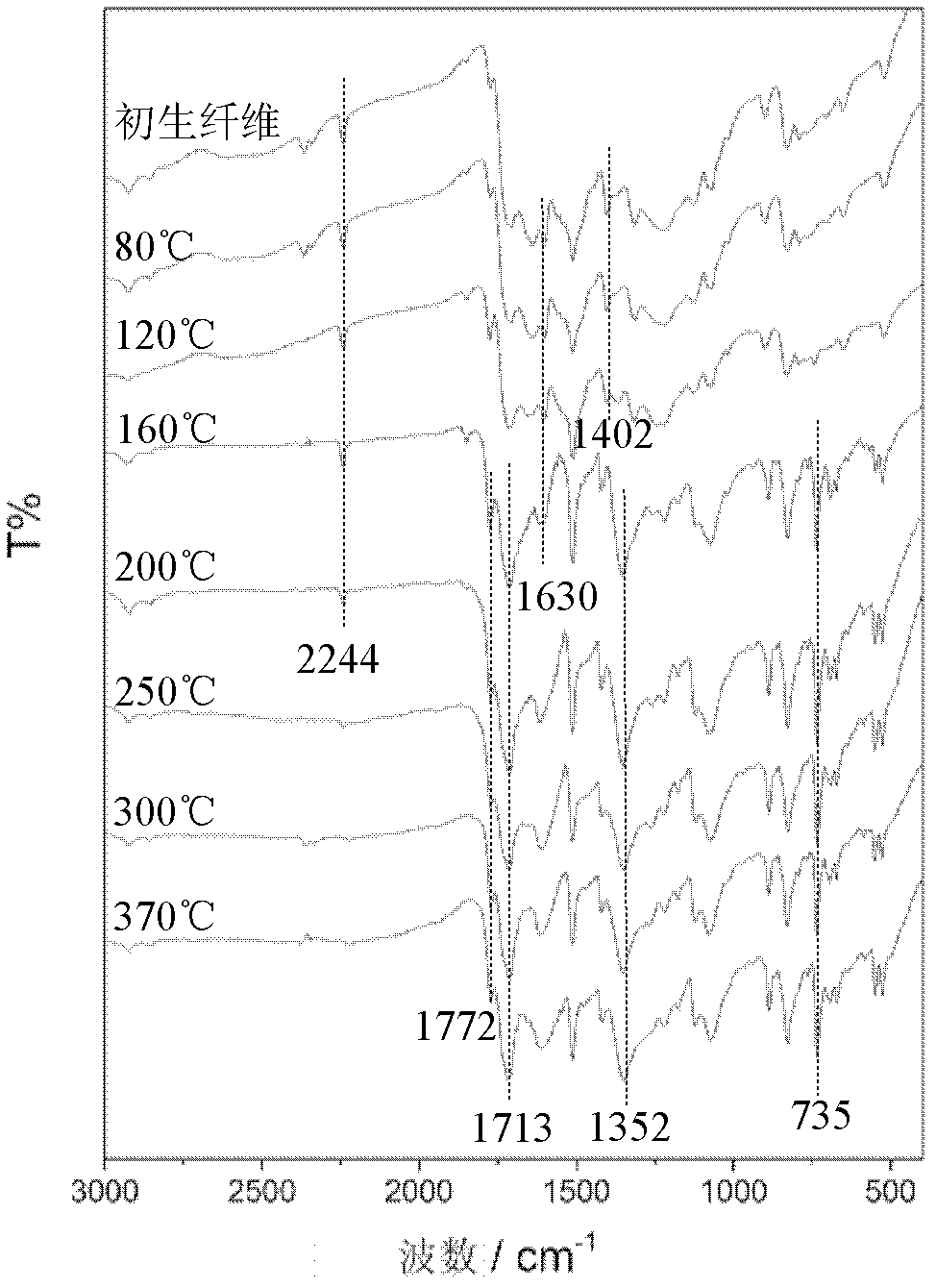

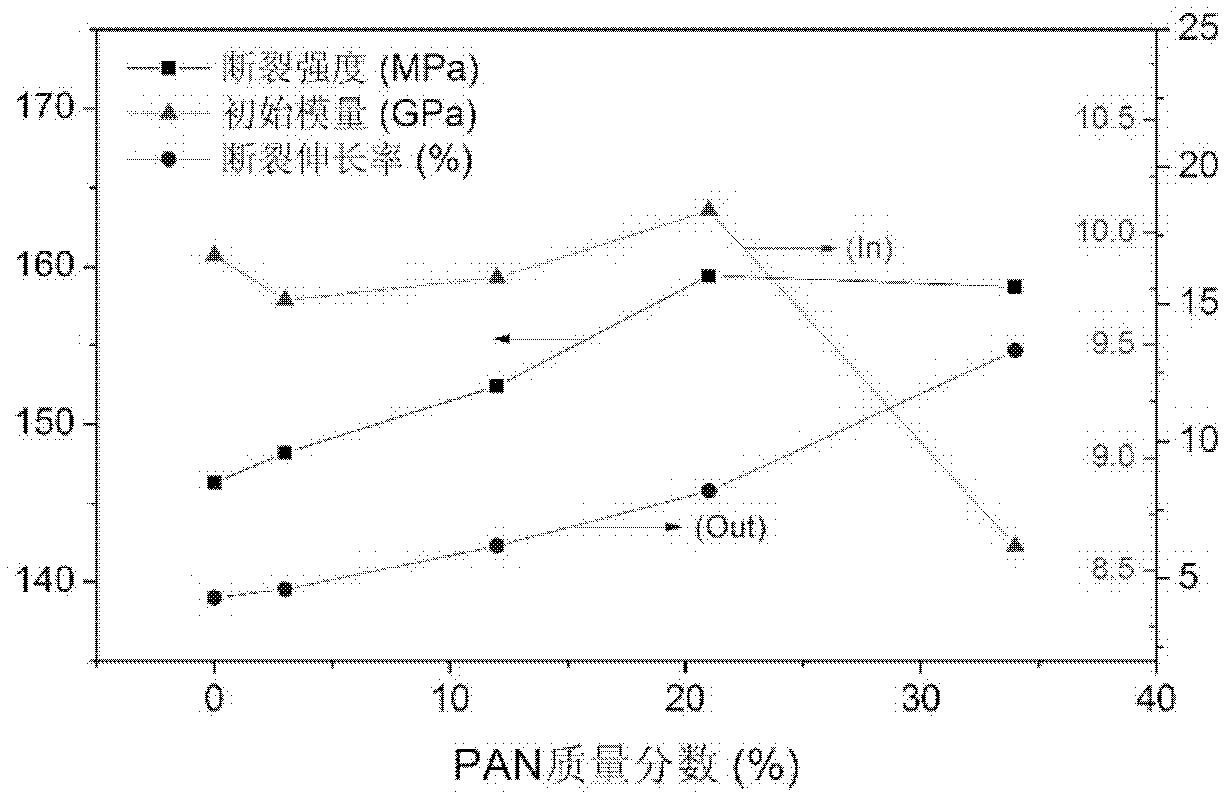

[0039] Synthesis and blending of spinning solution: In a three-neck flask, put. 4.4888g of p-phenylenediamine (p-PDA) was dissolved in 61mL of dimethylsulfoxide (DMSO), and 12.2740g of 3,3',4,4'-biphenyltetraacid dianhydride (BPDA) was added in batches. Adding time is 0.5h, keep stirring at 20-25°C for 4-5h until the apparent viscosity of PAA solution increases and remains stable; dissolve 5.5g PAN in 20mL DMSO, 2 protection, keep stirring for 2-3h until the powder is completely dissolved; N 2 Under protective conditions, take 2mL of PAN solution and add it to the PAA system. The mass fraction of PAN in the PAA / PAN blending component (excluding the solvent) is 3%, while stirring mechanically, and the temperature of the blending process is controlled within the range of 40-60°C , the blending and stirring time is 30-60min, until the mixing is uniform, so as to obtain the spinning solution blending precursor I;

[0040] Preparation of polyamic acid / polyacrylonitrile primary bl...

Embodiment 2

[0043] Synthesis and blending of spinning solution: In a three-neck flask, dissolve 11.2221gp-PDA in 100mL DMSO, add 30.8376g BPDA in batches, the cumulative addition time is 1h, and finally add 52mL DMSO, at 20-25℃ Continue to stir for 5-6h until the apparent viscosity of the PAA solution increases and remains stable; dissolve 5.5g of PAN in 20mL of DMSO, 2 protection, keep stirring for 2-3h until the powder is completely dissolved; N 2 Add the PAN solution to the PAA system under protective conditions, the mass fraction of the PAA / PAN blending component (excluding the solvent) accounted for by PAN is 12%, and mechanically stir at the same time, and the temperature of the blending process is controlled within the range of 40-60°C. The mixing time is 30-60 minutes until the mixing is uniform, so as to obtain the spinning solution blending precursor II;

[0044] Preparation of polyamic acid / polyacrylonitrile primary blended fiber: The spinning solution blended precursor II is ...

Embodiment 3

[0047] Synthesis and blending of spinning solution: In a three-neck flask, dissolve 5.6110g p-PDA in 50mL DMSO, add 15.4187g BPDA in batches, the cumulative addition time is 30min, and finally add 26mL DMSO, at 20-25℃ Stir continuously for 4-5h until the apparent viscosity of the PAA solution increases and remains stable; dissolve 5.5g of PAN in 20mL of DMSO, 2 protection, keep stirring for 2-3h until the powder is completely dissolved; N 2 Add the PAN solution to the PAA system under protective conditions, the mass fraction of the PAA / PAN blending component (excluding the solvent) accounted for by PAN is 21%, and mechanically stir at the same time, and the temperature of the blending process is controlled within the range of 40-60°C. The mixing time is 30-60 minutes until the mixing is uniform, so as to obtain the spinning solution blending precursor III;

[0048] Preparation of polyamic acid / polyacrylonitrile primary blended fiber: The spinning solution blended precursor II...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com