High heat resisting and high abrasion resistant polyvinyl chloride (PVC) modified material and preparation method thereof

A modified material and high wear-resistant technology, applied in the field of high heat-resistant, high-wear-resistant and environmentally friendly PVC modified materials and their preparation, can solve the problems of human health hazards, easy brittle cracking, and high viscosity

Active Publication Date: 2013-04-24

广东祺龙科技有限公司

View PDF7 Cites 33 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0002] Polyvinyl chloride (PVC) is one of the earliest industrialized and widely used general-purpose thermoplastics. It has light weight, high strength, insulation, flame retardancy, corrosion resistance, It has the advantages of excellent comprehensive performance, low price and wide source of raw materials; but it also has the following disadvantages: 1. Poor toughness, easy to be brittle when impacted, so it cannot be used as a structural material. In addition, the brittleness of polyvinyl chloride is greatly affected by temperature. Large, the lower limit of general PVC products is -15°C, and the lower limit of soft PVC is -30°C; 2. Poor thermal stability, it begins to decompose HCl at 100°C, and decomposes more rapidly when it is higher than 150°C. The melting temperature of PVC is about 210°C; 3. The viscosity of PVC is extremely high and its fluidity is extremely poor, which limits its use to a certain extent.

[0006]The performance indicators of most of the existing PVC materials are only meeting the basic requirements of national standards. For many special environments such as high temperature and abrasive environments, the current PVC The performance of the material cannot reliably meet the needs of long-term use under high temperature and wear conditions, and the heat and wear resistance of PVC materials need to be further optimized and improved; in addition, the existing PVC sheathed cables, PVC plugs, PVC films and PVC pipes There is quite serious pollution, which will cause certain harm to human health, and it is particularly important to develop an environmentally friendly PVC modified material.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

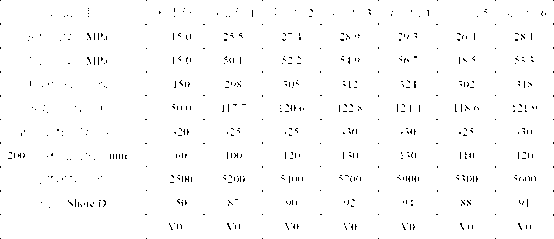

Embodiment 1

[0058] Example 2

Embodiment 2

[0060] Example 3

Embodiment 3

[0062] Example 4

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention relates to the technical field of polyvinyl chloride composite materials, in particular to high heat resisting and high abrasion resistant polyvinyl chloride (PVC) modified materials and a preparation method of the high heat resisting and high abrasion resistant PVC modified materials. The modified materials comprise the following raw materials, by weight, 80-120 parts of PVC resin, 25-60 parts of stuffing bulking agents, 21-60 parts of plasticizer, 1-10 parts of chlorinated polyvinyl chloride, 1-10 parts of fire retardant, 1-10 parts of stabilizer, 1-10 parts of impact modifier and 0.2-2 parts of lubricating agents. The raw materials are weighed according to parts by weight and are blended. After being blended, the raw materials are extruded out to be granulated through a double-screw extruder to produce the modified materials. The modified materials are good in heat resisting property and abrasion resistant property, environment-friendly, high in strength, good in flame retardant effect, strong in compressing property and toughness, good in processing property and good in comprehensive property. The preparation method is simple in craft, convenient to operate and control, stable in quality and high in production efficiency, and can be produced in a large scale industrialization mode.

Description

technical field [0001] The invention relates to the technical field of polyvinyl chloride composite materials, in particular to a high heat-resistant, high-abrasion and environment-friendly PVC modified material and a preparation method thereof. Background technique [0002] Polyvinyl chloride (PVC) is one of the earliest industrialized and widely used general-purpose thermoplastics. It has the advantages of light weight, high strength, insulation, flame retardancy, corrosion resistance, excellent comprehensive performance, low price and wide source of raw materials; but also There are the following disadvantages: 1. The toughness is poor, and it is easy to be brittle when impacted, so it cannot be used as a structural material. In addition, the brittleness of polyvinyl chloride is greatly affected by temperature. The lower limit of general PVC products is -15°C. The lower limit of use of PVC is -30°C; 2. Poor thermal stability, it begins to decompose HCl at 100°C, and decom...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C08L27/06C08L27/24C08L9/06C08L9/02C08K13/02C08K3/26C08K3/36C08K5/12C08K5/1515C08K3/22B29B9/06B29C47/92B29C48/92

CPCB29C48/04B29C48/40B29C48/875B29C48/92B29C2948/92704B29C2948/92895

Inventor 宁建华朱其华

Owner 广东祺龙科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com