Lubricating grease for automobile safety belt system

A safety belt and lubricating grease technology, which is applied in the field of lubricating grease, can solve the problems of resource waste, poor wear resistance, and insufficient lubrication life, and achieve the effects of improving wear resistance and heat resistance, small friction coefficient, and excellent effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

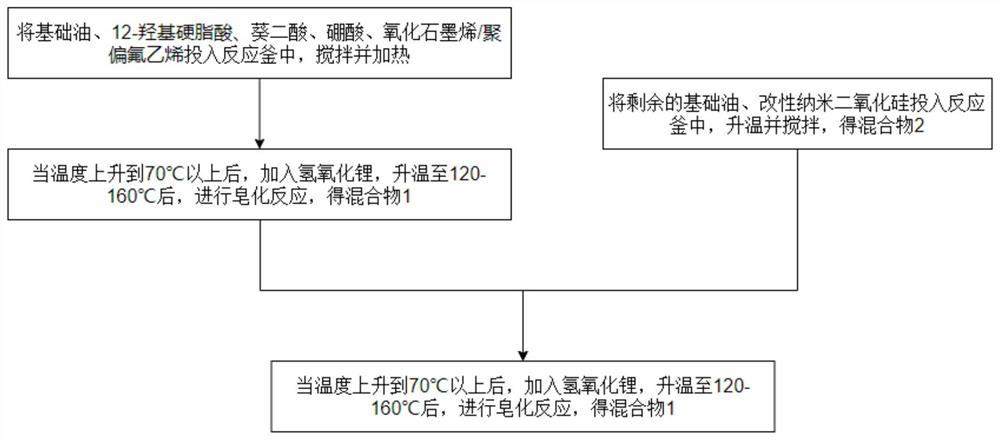

Method used

Image

Examples

Embodiment 1

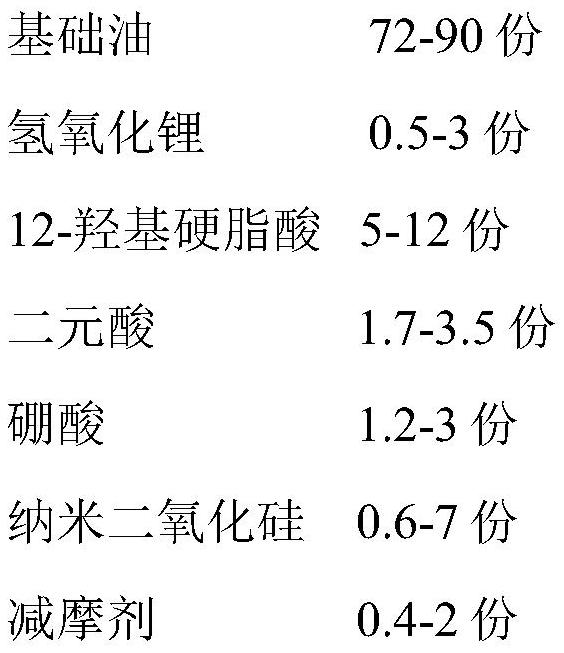

[0040] A kind of automobile safety belt system lubricating grease, comprises the component of following proportioning by weight:

[0041]

[0042] The lubricating grease in this embodiment is a complex lithium-based lubricating grease, which is a new type of lubricating grease prepared by compounding nano-silica materials, especially modified nano-silica materials, and adding a friction reducer. The automobile safety belt system lubricating grease prepared in this embodiment has a lower friction coefficient, better wear resistance and heat resistance, and has excellent effect when applied to the automobile safety belt system.

Embodiment 2

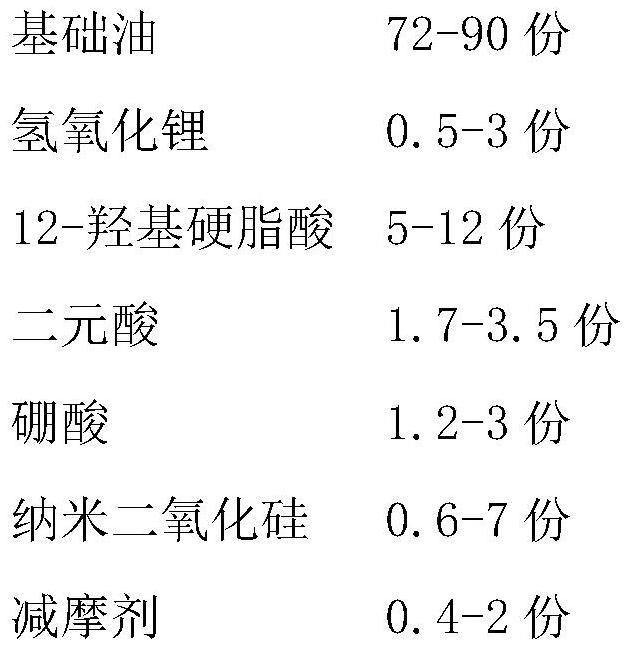

[0044] A kind of automobile safety belt system lubricating grease, comprises the component of following proportioning by weight:

[0045]

[0046] The lubricating grease in this embodiment is a complex lithium-based lubricating grease, which is a new type of lubricating grease prepared by compounding nano-silica materials, especially modified nano-silica materials, and adding a friction reducer. The automobile safety belt system lubricating grease prepared in this embodiment has a lower friction coefficient, better wear resistance and heat resistance, and has excellent effect when applied to the automobile safety belt system.

[0047]Compared with Example 1, the present invention adds more modified nano-silica and anti-friction agent, that is, the dosage ratio between base oil and modified nano-silica, and the dosage between base oil and friction reducer. The ratio is larger, and the automobile safety belt system lubricating grease prepared in this embodiment has a lower fr...

Embodiment 3

[0049] A kind of automobile safety belt system lubricating grease, comprises the component of following proportioning by weight:

[0050]

[0051] The lubricating grease in this embodiment is a complex lithium-based lubricating grease, which is a new type of lubricating grease prepared by compounding nano-silica materials, especially modified nano-silica materials, and adding a friction reducer. The automobile safety belt system lubricating grease prepared in this embodiment has a lower friction coefficient, better wear resistance and heat resistance, and has excellent effect when applied to the automobile safety belt system.

[0052] This embodiment is a preferred embodiment of the automobile safety belt system lubricating grease of the present invention. In many embodiments, the automobile safety belt system lubricating grease prepared in this embodiment has the lowest friction coefficient, the best friction performance, and the most Excellent wear resistance, heat resist...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com