Patents

Literature

30results about How to "Improve wear and heat resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

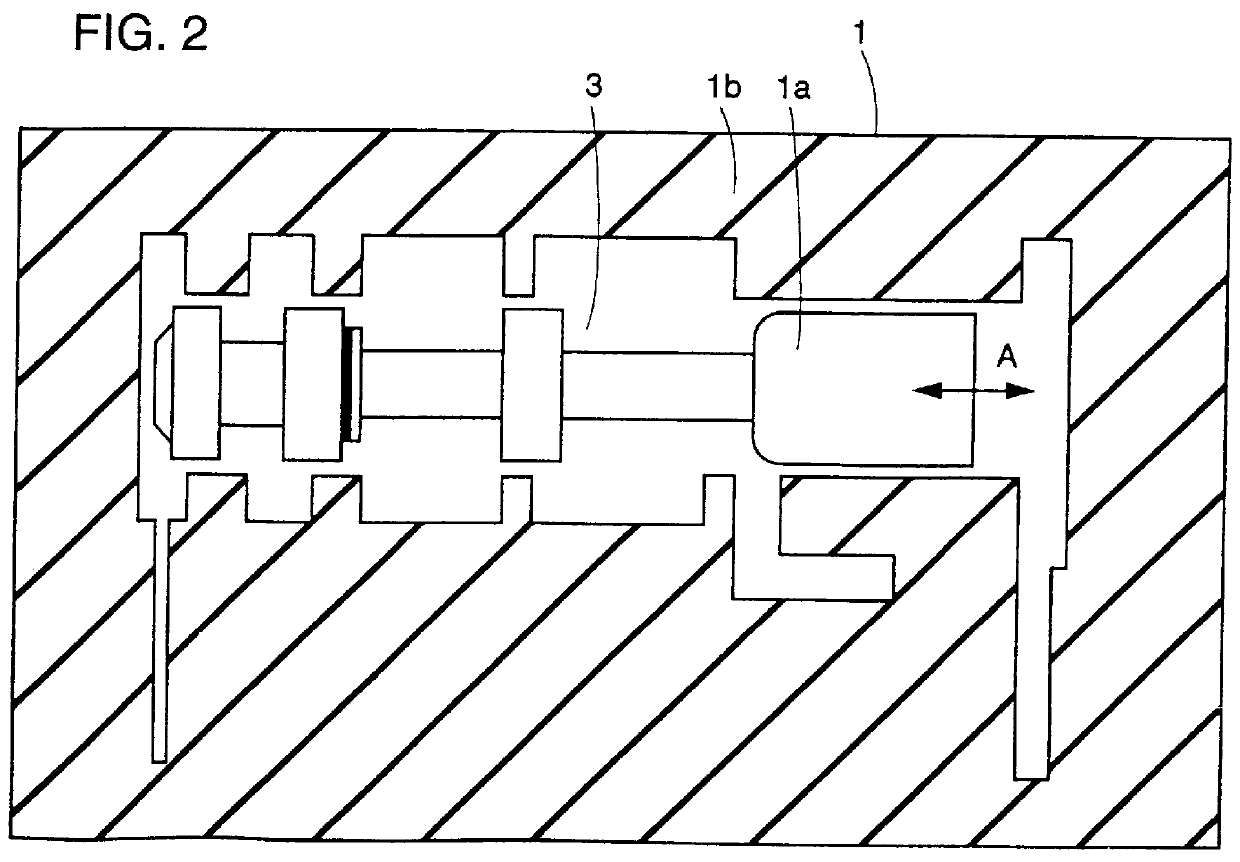

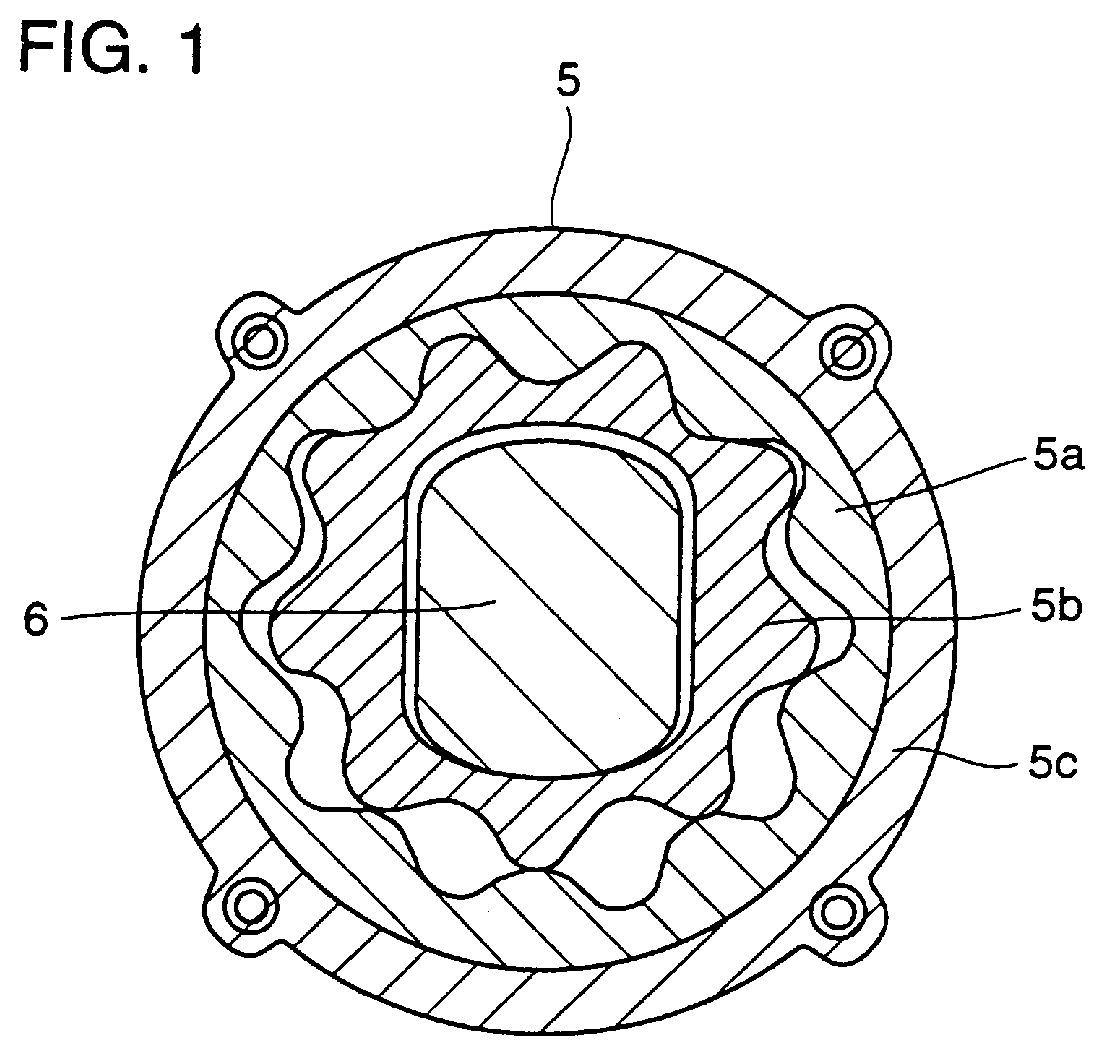

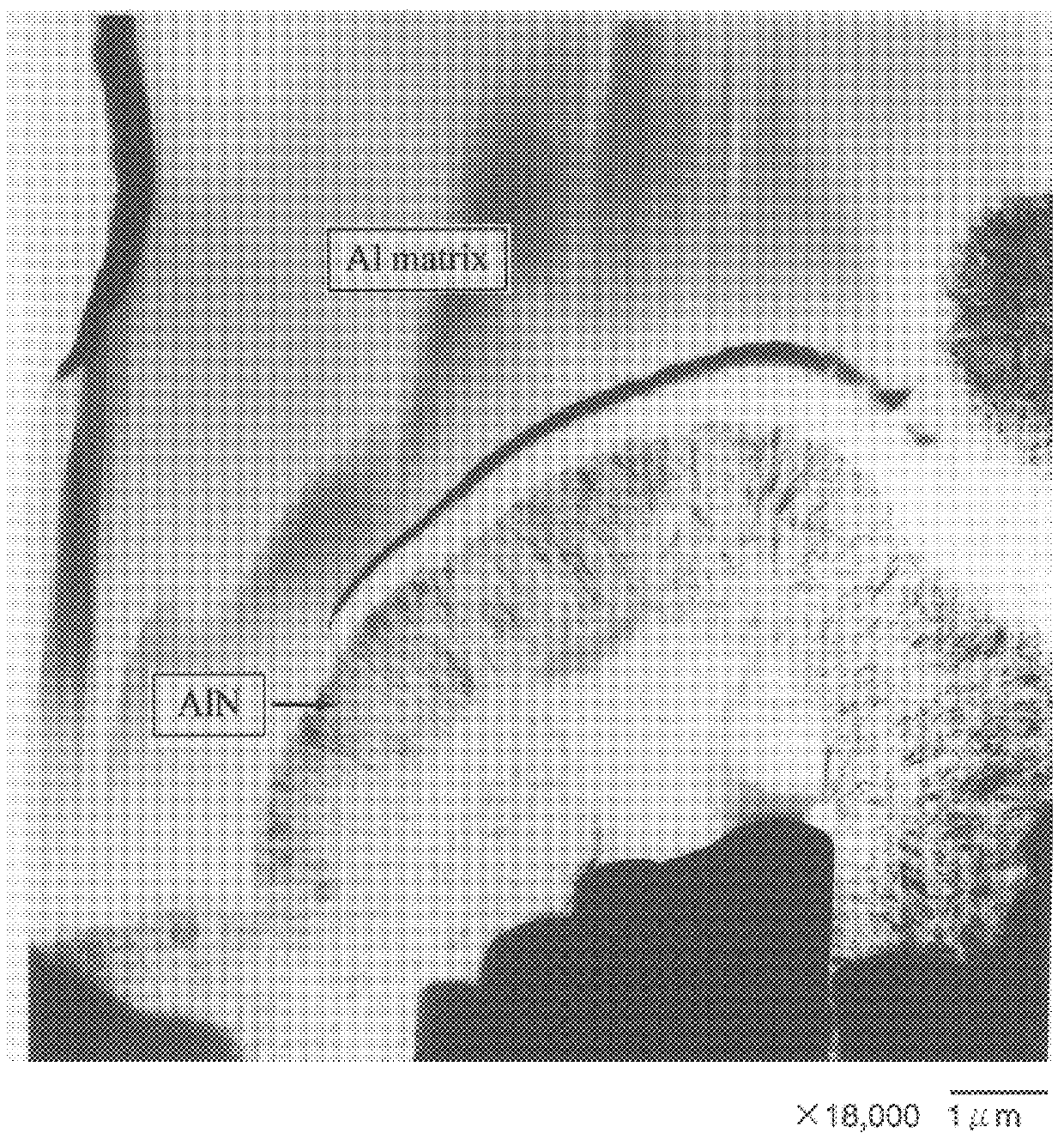

Sliding member and oil pump

InactiveUS6089843AIncrease heatIncrease resistanceOscillating piston enginesEngine of intermeshing engagement typePorosityDrive shaft

An outer rotor and an inner rotor are formed of sintered aluminum alloy. The sintered aluminum alloy contains 0.5 wt % to 11 wt % of aluminum nitride. Porosity of the sintered aluminum alloy for outer rotor is 3 vol % to 15 vol %. Porosity of the sintered aluminum alloy for inner rotor is 2 vol % to 10 vol %. Outer rotor and inner rotor are set in a pump case. A rotary driving shaft formed of steel is inserted to a through hole of inner rotor. A press fit member is inserted at a press fit surface of inner rotor and rotary driving shaft. Accordingly, sliding members formed of sintered aluminum alloy which reduces seizure and abrasive wear of the inner and outer rotors can be provided, and in addition, an oil pump of which wear and damage at the inner rotor inner diameter surface is suppressed, can be provided.

Owner:SUMITOMO ELECTRIC IND LTD

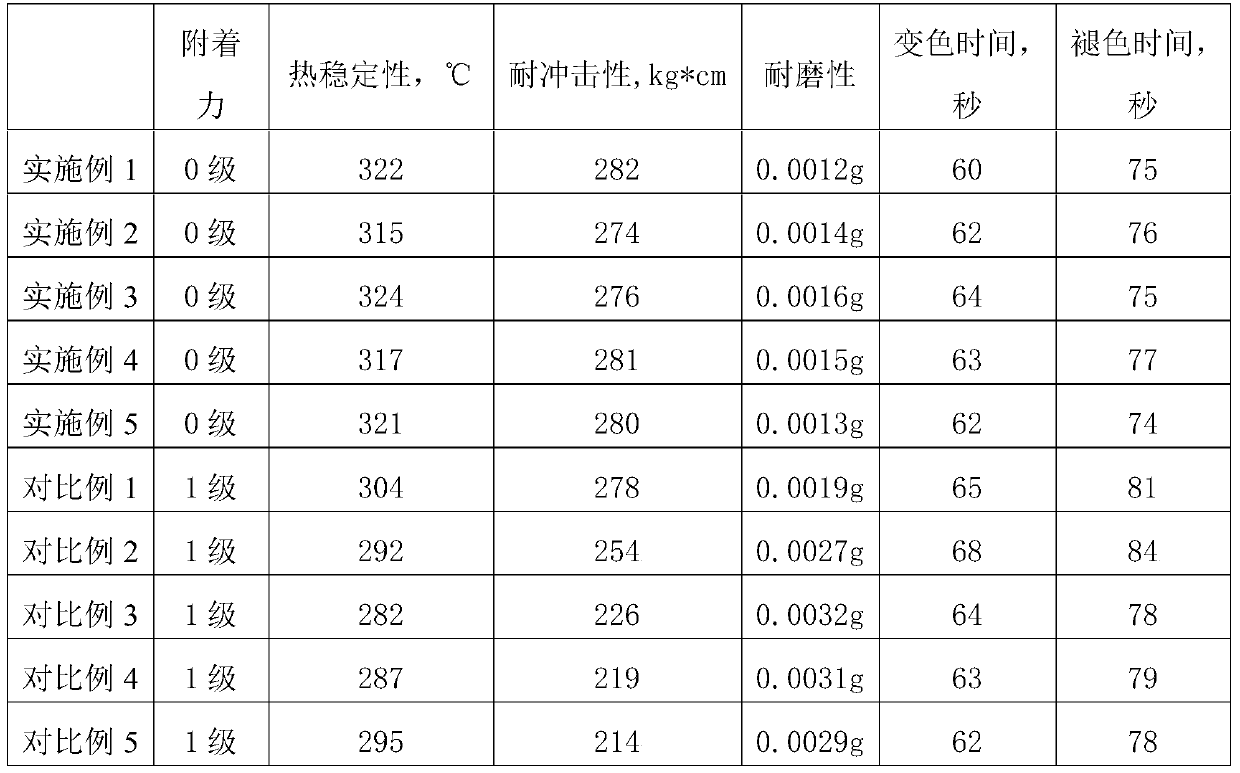

Nonstick coating containing graphene material, and preparation method thereof

ActiveCN110358442ASensitive over-temperature reminder effectReversible over-temperature reminder effectFireproof paintsCooking-vessel materialsFatty alcoholAmmonium sulfate

The invention discloses a nonstick coating containing a graphene material. The nonstick coating is formed by a bottom layer and a surface layer; the bottom layer comprises, by weight, 50-90 parts of apolytetrafluoroethylene / polysulfone blend, 0.5-2 parts modified graphene oxide, 1-5 parts of a thermochromic pigment, 0.8-1.2 parts of modified silicon carbide whiskers, 1.5-3 parts of an additive and 15-35 parts of deionized water; and the surface layer comprises, by weight, 35-75 parts of polytetrafluoroethylene resin, 1.5-5 parts of modified calcium carbonate whiskers, 3-8 parts of fatty alcohol polyoxyethylene ether ammonium sulfate, 5-10 parts maleic anhydride and 35-60 parts deionized water. Different raw material components of the bottom layer and the surface layer are reasonably combined, so the obtained nonstick coating has the advantages of good over-temperature prompting function, facilitation of control of the cooking heat, excellent high temperature wear resistance, and prolongation of the service life of a nonstick pan.

Owner:宁波市金象厨具有限公司

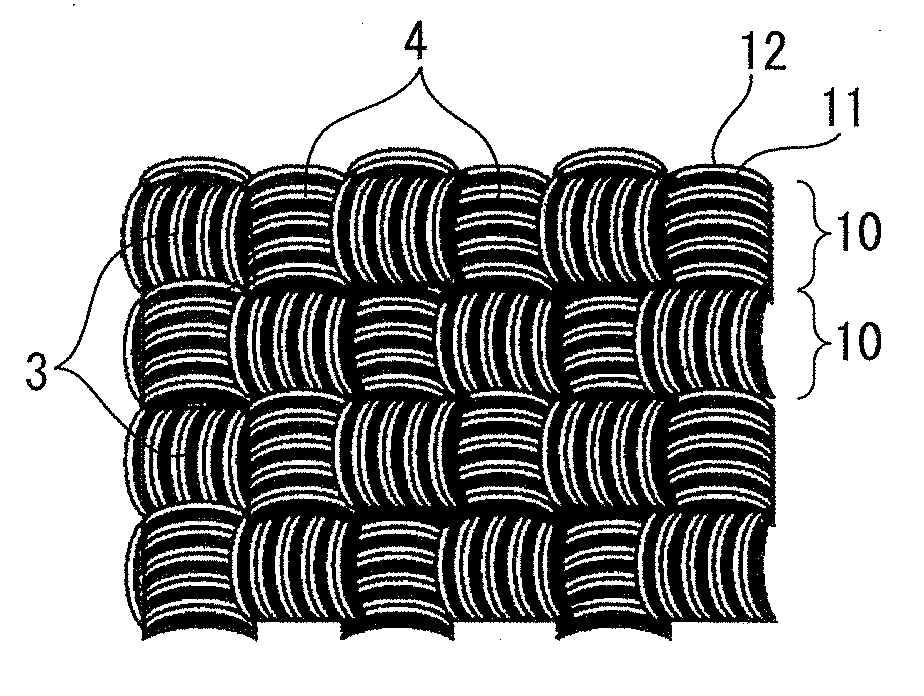

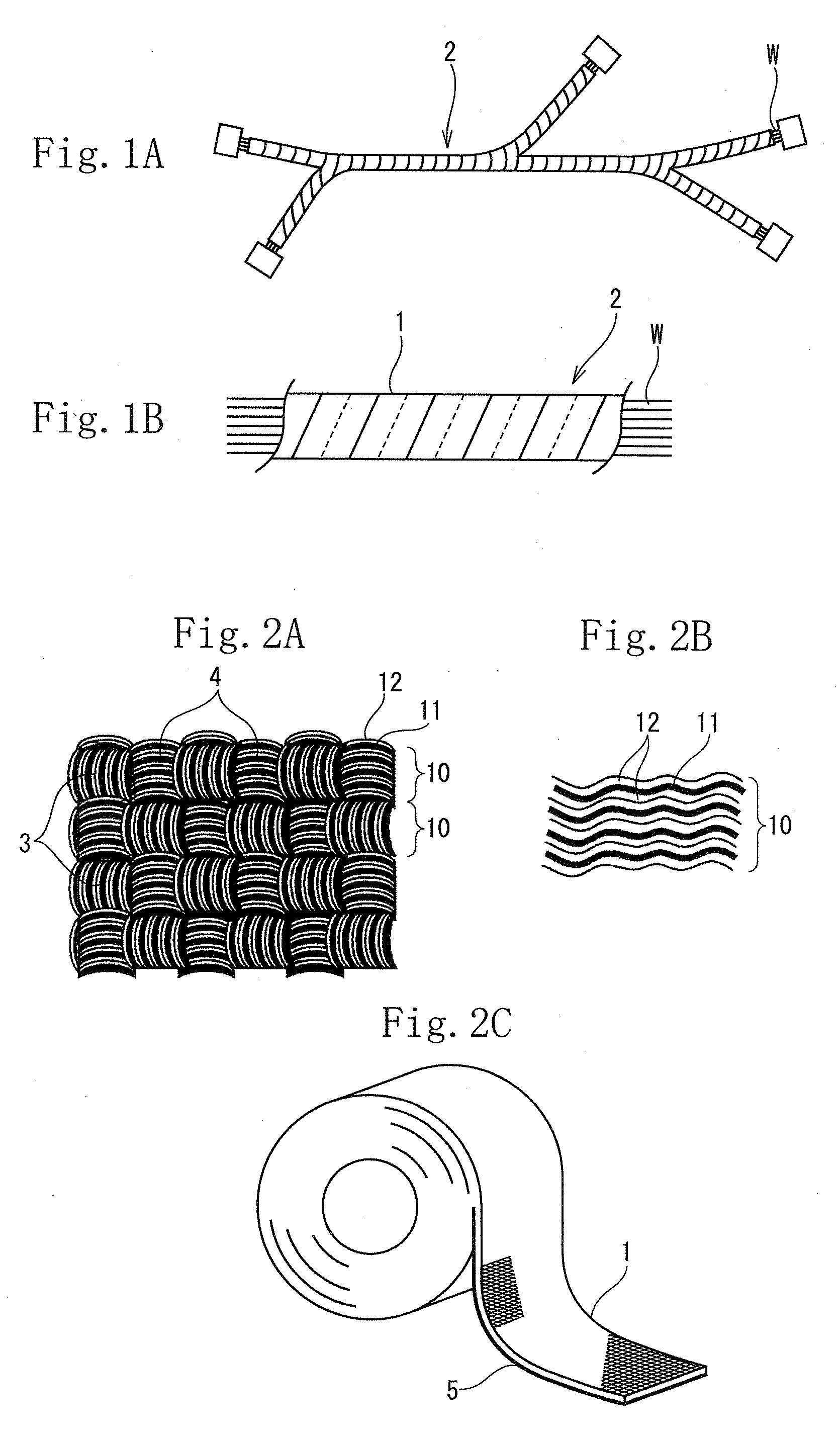

Tape for electric wire

InactiveUS20110244747A1Improve heat resistanceImprove wear resistancePlastic/resin/waxes insulatorsFilm/foil adhesivesPolypropyleneGeneral purpose

A tape which has enhanced heat resistance, flame retardancy, and wearing resistance and is suitable for use in bundling a group of electric wires which will be laid in a high-temperature environment. The tape is configured using the same yarns (10) each composed of high-function fiber filaments (11) and general-purpose fiber filaments (12), as a warp (3) and a weft (4). The high-function fiber filaments are superior to the general-purpose fiber filaments in heat resistance, flame retardancy, and wearing resistance. The high-function fiber filaments are of at least one kind selected from paraaramid fibers, polyarylate fibers, ultrahigh-molecular polyethylene fibers, glass fibers, and polyphenylene sulfide fibers. The general-purpose fiber filaments comprise at least one selected from polyesters, polyethylene, and polypropylene.

Owner:SUMITOMO WIRING SYST LTD

Heat-resistant rare-earth magnesium alloy containing silicon, zinc and Gd(-Y) and preparation method thereof

The invention discloses heat-resistant rare-earth magnesium alloy containing silicon, zinc and Gd(-Y), and a preparation method thereof. The alloy comprises the following components in percentage by weight: 10-20% of Gd, 0.5-6% of Y, 0.1-5% of Si, 0.1-5% of Zn, 0-1% of Zr, less than 0.02% of all impurity elements, and the balance of Mg. The magnesium alloy disclosed by the invention is obtained by smelting and subsequent heat treatment, is simple in process and high in production efficiency, and has excellent characteristics of high strength, high abrasive resistance, good plasticity and the like at 200-300 DEG C due to existence of silicon, zinc and high-content Gd(-Y) rare-earth elements.

Owner:SHANGHAI JIAO TONG UNIV

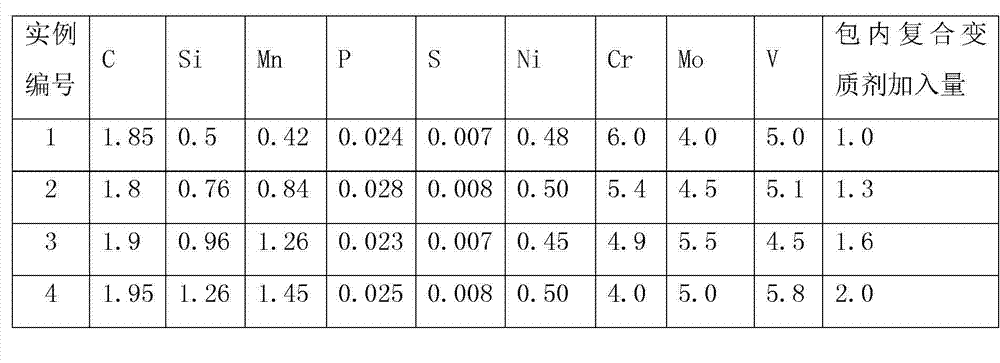

Method for modifying centrifugal composite casting high-speed steel roll outer layer

ActiveCN102828123AImprove wear and heat resistanceGuaranteed toughness and hardnessFerrosiliconHigh-speed steel

The invention relates to the technical field of high-speed steel rolls, and in particular relates to a method for modifying a centrifugal composite casting high-speed steel roll outer layer, which is characterized in that when the outer layer high-speed steel smelting is completed and discharged, composite modificator is added into a steel ladle to modify the high-speed molten iron, the adding amount of the composite modificator is 1.0-2.0% of the weight of the molten iron, and the reaction temperature is 1500-1600 DEG C. The composite modificator comprises the following chemical constituents by weight percent: 50-55% of FeV50, 50-55% of rare earth ferrosilicon alloy FeSiRe21, 20-25% of silicon barium alloy FeBa5Si60 and 5-10% of Al. Compared with the prior art, the method has the advantages that casting grains are thinned, the states of chromium compounds and carbide are improved, fine spherical MC type carbide is uniformly dispersed and distributed, so the wear resistance and heat resistance of the high-speed steel roll outer layer are improved, and the millimeter rolled metal of the roll is increased by 25%-30% comparatively.

Owner:鞍钢轧辊有限公司

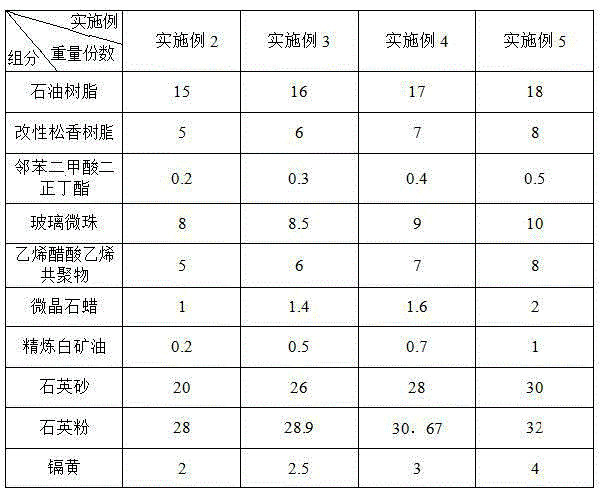

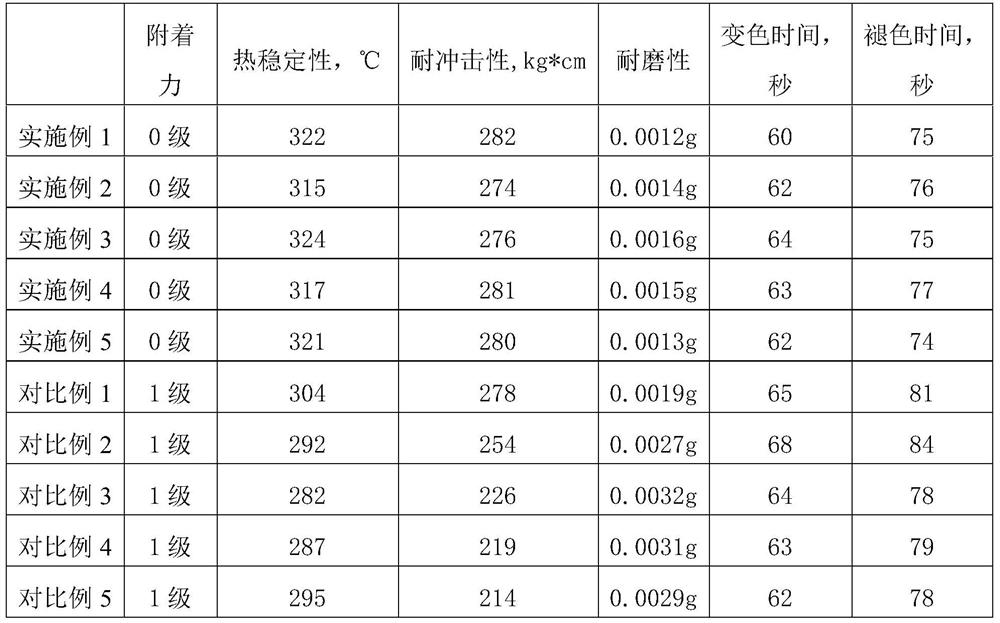

Heat melting high-wear-resistant anti-pollution yellow traffic marking material and preparation method thereof

The invention discloses a heat melting high-wear-resistant anti-pollution yellow traffic marking material and a preparation method thereof. The preparation method is used for preparing the traffic marking material in the technical field of traffics. The heat melting high-wear-resistant anti-pollution yellow traffic marking material comprises the following components: petroleum resin, modified rosin resin, di-n-butyl phthalate, glass beads, an ethylene vinyl acetate copolymer, microcrystalline wax, refined white mineral oil, quartz sand, quartz powder and cadmium yellow. The traffic marking material prepared by using the preparation method not only can be used for improving the wear resistance and anti-pollution capacity of a traffic marking, but also can be used for increasing the adhesive force of the traffic marking.

Owner:BAODING VICTORY TRAFFIC FACILITIES ENG CO LTD

Integral type hard alloy cutter for materials difficult to machine and preparation method thereof

InactiveCN107740005AImproves strength and hardnessImprove wear and heat resistanceCemented carbideMachining process

The invention discloses an integral type hard alloy cutter for materials difficult to machine and a preparation method thereof. The material of the hard alloy cutter comprises the following components, by weight, 16-23 parts of titanium niobium alloy, 26-34 parts of copper molybdenum alloy, 22-28 parts of iron-nickel alloy, 4-5 parts of silicon sulfide, 9-11 parts of graphene, 4-6 parts of rare earth, 20-28 parts of graphite carbon fiber powder, 10-18 parts of cubic boron carbide micro powder, 15-18 parts of silicon dioxide, 9-12 parts of unsaturated resin, 5-9 parts of tungsten silicide and 5-7 parts of molybdenum carbide. The integral type hard alloy cutter has the beneficial effects that the rare earth, the graphite carbon fiber powder, the cubic boron carbide micro powder, the silicondioxide and the like are added, and therefore hardness and strength of the cutter are improved greatly; abrasion resistance and heat resistance of the cutter are also improved remarkably; the servicelife of the cutter is long, and practical cost is low; and pollution of the machining process is little.

Owner:NANCHANG INST OF TECH

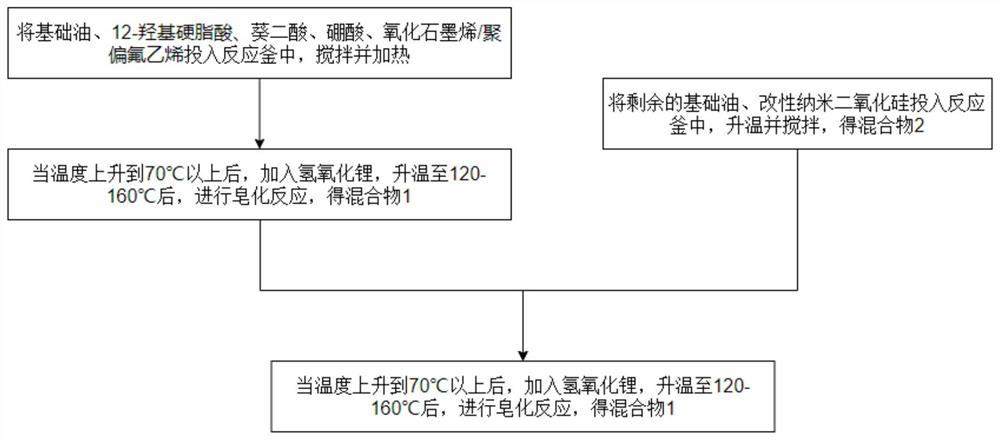

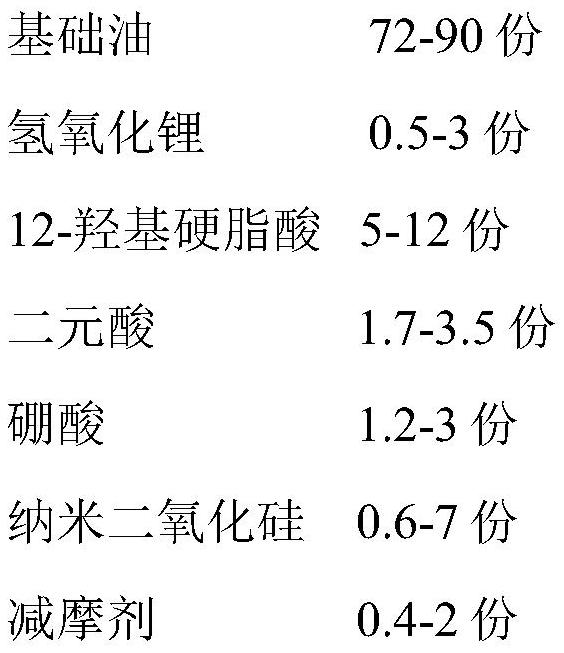

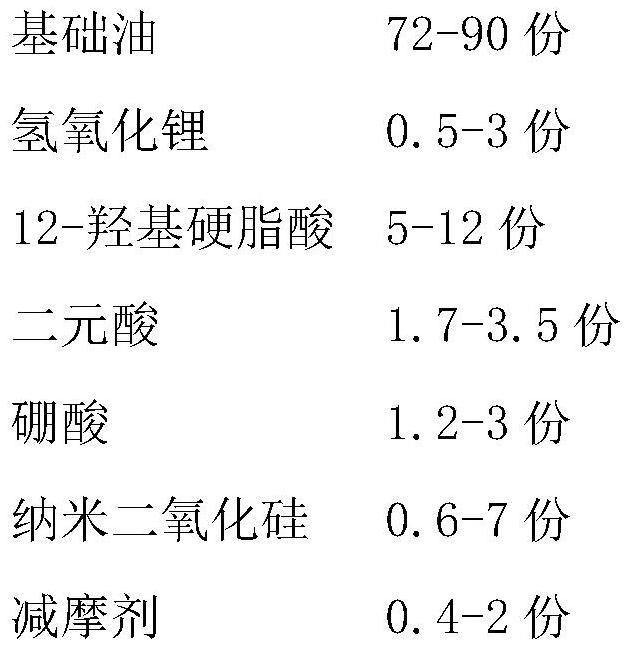

Lubricating grease for automobile safety belt system

InactiveCN111961517AReduce coefficient of frictionImprove stabilityLubricant compositionLithium hydroxideHydroxystearic Acid

The invention relates to lubricating grease for an automobile safety belt system. The lubricating grease comprises the following components in parts by weight: 72-90 parts of base oil; 0.5 to 3 partsof lithium hydroxide; 5 to 12 parts of 12-hydroxystearic acid; 1.7 to 3.5 parts of a binary acid; 1.2 to 3 parts of boric acid; 0.6 to 7 parts of nano silicon dioxide; 0.4 to 2 parts of a friction reducing agent; wherein the base oil comprises at least one of mineral base oil, synthetic base oil or naphthenic base mineral oil. The lubricating grease provided by the invention is composite lithium-based lubricating grease, and as an innovation point of the invention, the lubricating grease is composite with a nano silicon dioxide material, especially a modified nano silicon dioxide material, andis a novel lubricating grease prepared by adding an antifriction agent. A safety belt in an automobile safety belt system is frequently and repeatedly stretched, the lubricating grease added with thefriction reducing agent is small in friction coefficient and good in stability, the overall wear resistance, heat resistance and other properties of the lubricating grease are improved through the modified nano silicon dioxide, and the use effect is good when the lubricating grease is applied to the automobile safety belt system.

Owner:广东阿特斯新材料科技有限公司

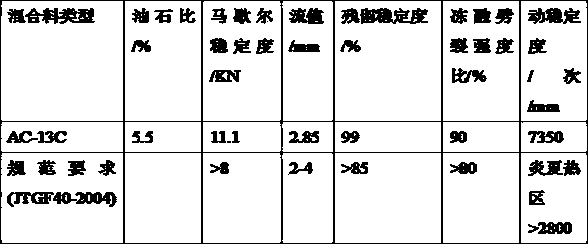

Composite asphalt modifier

The invention discloses a composite asphalt modifier. The composite asphalt modifier comprises main materials and assistants, the percentage of the main materials account foris 75-80 percent, and the percentage of the assistants is 20-25 percent. A preparation method of the composite asphalt modifier is as follows: according to the demand of a customer, the proportions of the compositions in the main materials and the assistants and the proportions of the main materials and the assistants are determined via tests, and then the mixed main materials and the assistants are independently packed so as to obtain the finished product. The composite asphalt modifier provided by the invention is low in production investment, simple in modification process and better in stability after modification, and has a very good popularization value.

Owner:LIUZHOU BOZE SCI & TECH

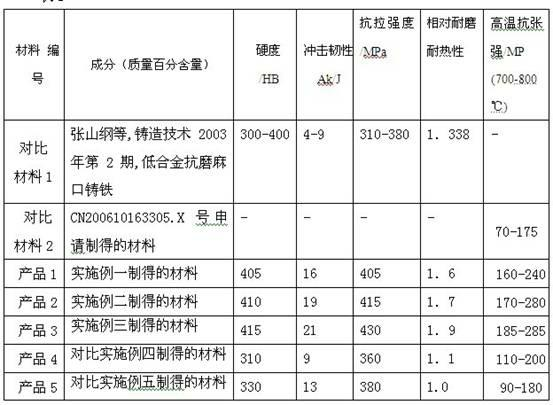

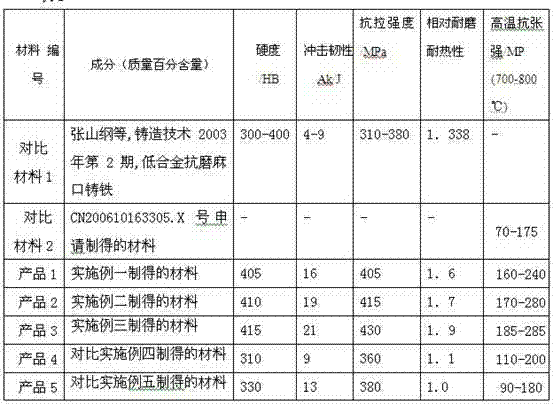

Wear-resistant and heat-resistant mottled cast iron material and preparation method thereof

InactiveCN102051545AImprove the strengthening and toughening effectImprove toughnessMaterials scienceCast iron

The invention provides a wear-resistant and heat-resistant mottled cast iron material and a preparation method thereof. The wear-resistant and heat-resistant mottled cast iron material has good performance; and the preparation method is simple in process, low in production cost and suitable for industrial production. Mottled cast iron is utilized as a substrate for the wear-resistant and heat-resistant mottled cast iron material, wherein metal wire clusters formed by iron wires are distributed in the substrate; the diameter of the iron wires is 0.2-2mm; the diameter of the metal wire clusters is 10-15cm; and the iron wires account for 5-40% of the material by volume.

Owner:金湖中博物联网科技有限公司

High-hardness heat-resistant coating for anti-dazzle glass

The invention discloses a high-hardness heat-resistant coating for anti-dazzle glass. Raw materials of the high-hardness heat-resistant coating comprise organosilicon modified epoxy resin, alkyd resin, polychloroacetic acid, modified vanadium dioxide, a styrene elastomer, nanometer tin antimony oxide, a polysiloxane prepolymer, styrene, o-phenylenediamine, acetylacetone, acrylate, nanometer titania, alumina, mica powder, sodium dodecylbenzenesulphonate, benzophenone, a leveling agent, an antifoaming agent, a dispersing agent, a thickener, a stabilizer and an adhesive. The coating for the anti-dazzle glass has good photopermeability and excellent wear resistance and heat resistance.

Owner:ANHUI HERUN SPECIAL GLASS CO LTD

Automotive engine piston made of novel material

InactiveCN104632456AImprove solid solubilityImprove performanceMachines/enginesPistonsHeat resistanceAlloy

The invention discloses an automotive engine piston made of a novel material and belongs to the field of automotive engine components. The novel material is rapid set high-silicon aluminum alloy, a certain novel tissue structure characteristic, namely ultra-fine microstructure is obtained through the rapid set technique, the solid solubility limit of the alloy is improved, the heights of components are even, segregation is nearly or completely avoided, a novel metastable phase is formed, and defect density is improved. The material has the advantages of being light, high in strength, high in corrosion resistance and heat resistance, low in thermal expansivity and the like, the solid solubility of Si in an aluminum matrix can be improved, grains are refined, the material is well matched with the matrix, and the performance of the alloy is improved remarkably.

Owner:QINGDAO LIBO AUTO PARTS PRECISION CASTING

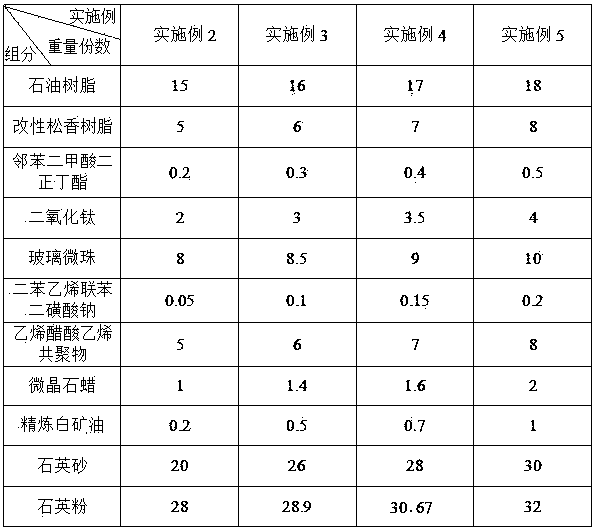

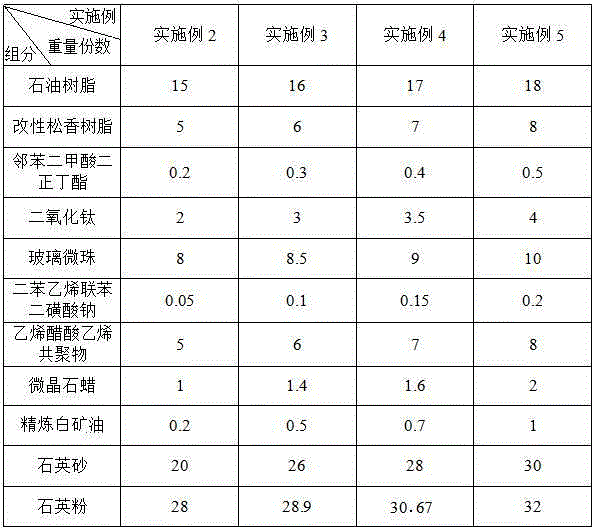

Heat-fused highly-wear-resisting anti-pollution white traffic marking material and preparation method thereof

ActiveCN103951931AGood weather resistanceImprove wear resistanceMicrocrystalline waxMaterials science

The invention discloses a heat-fused highly-wear-resisting anti-pollution white traffic marking material and a preparation method thereof, and the preparation method is used for manufacturing the traffic marking material in the traffic technical field. The heat-fused highly-wear-resisting anti-pollution white traffic marking material comprises the following components: petroleum resin, modified rosin resin, di-n-butyl ortho-phthalate, titanium dioxide, glass bead, stilbene biphenyl sodium disulfonate, ethylene vinyl acetate copolymer, microcrystalline wax, refined white mineral oil, quartz sand and quartz powder. The traffic marking material prepared by adopting the preparation method disclosed by the invention not only can be used for improving the wear resistance and anti-pollution capacity of the traffic marking, but also strengthening the adhesion force of the traffic marking.

Owner:BAODING VICTORY TRAFFIC FACILITIES ENG CO LTD

Aluminum-manganese-titanium-iron alloy as deoxidant in steelmaking

An AlMnTiFe alloy used for deoxidizing and alloying in smelting steel contains Al (15-60 wt.%), Mn (3-45), Ti (10.5-25) and Fe (rest). It can improve properties of steel, such as plasticity, toughness, alloying level and resistance to corrosion and high temp.

Owner:本溪冶炼厂

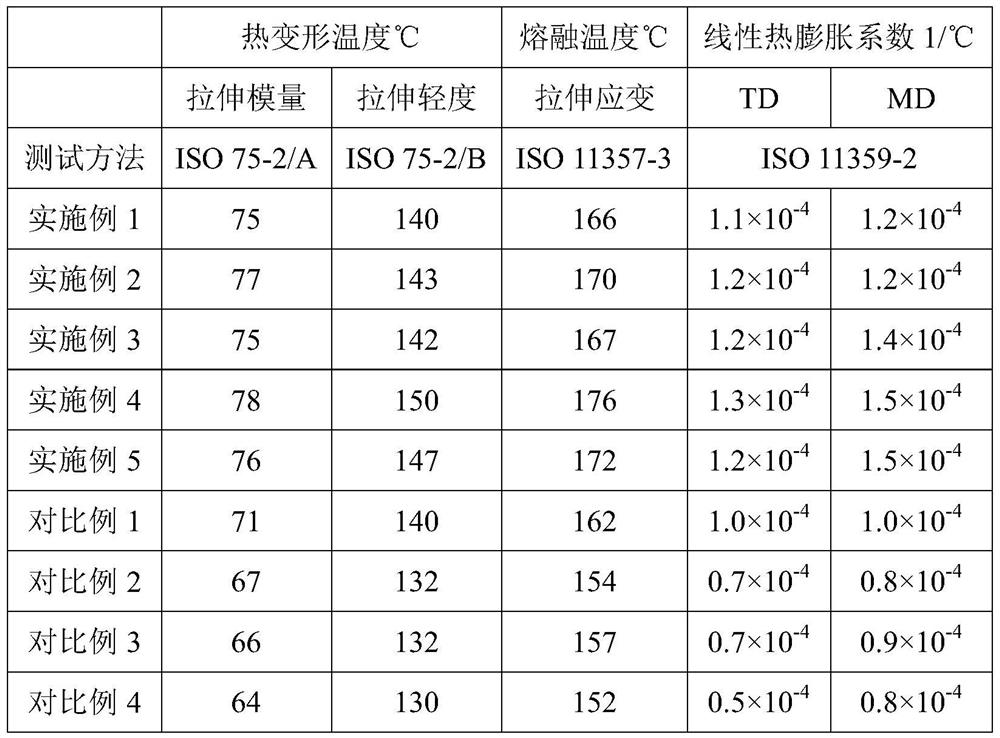

Modified POM copolymer resin and preparation process thereof

The invention belongs to the technical field of resin modification, and particularly relates to modified POM copolymer resin and a preparation process thereof. The POM copolymer resin is prepared from homopolyformaldehyde, copolyformaldehyde, a composite nucleating agent, rubber particles, a fiber filler and a stabilizer. The composite nucleating agent comprises a mixture of an inorganic nucleating agent and an organic nucleating agent, the inorganic nucleating agent comprises one or more of nano silicon dioxide, nano calcium carbonate and boron nitride, and the organic nucleating agent comprises one of melamine formal, polyamide and a carbon nanotube. The resin is reinforced and modified through a re-checking nucleating agent, rubber particles and a fiber filler, the crystallinity of the resin is improved, the toughness of the resin is improved, the impact strength, flexibility, rigidity and creep resistance of the resin material are remarkably improved, the wear resistance and heat resistance of the resin material are improved, and the used material has the characteristic of low VOC; and the modified POM copolymer resin disclosed by the invention is applied to the field of automobiles and can meet the ultralow emission performance required by the automobile market.

Owner:广州搜料信息技术有限公司

Amorphous diffusion alloy and preparation method thereof

InactiveCN104513911AImprove impact resistanceImprove stretch resistance to fatigueManganeseRare earth

The invention discloses an amorphous diffusion alloy and a preparation method thereof. The amorphous diffusion alloy is prepared from nickel coated titanium carbide, boron carbide, mixed rare earth, ferrotitanium powder, superfine high-carbon chromium iron powder, silicon carbide whiskers, boron nitride, lanthanum oxide, cerium oxide, zirconium oxide, copper powder, high-nitrogen ferrochrome, cobalt powder, manganese powder, tungsten powder, nanometer titanium oxide, and the balance of superfine iron powder, wherein the mixed rare earth is heavy rare earth or light rare earth. The amorphous diffusion alloy is mainly used in iron-based powder metallurgy products, can improve the impact, tensile fatigue, wear and heat resistance of the products, can partially or completely substitute noble metal elements, and reduces the cost of the products.

Owner:莱芜市冠隆纳米科技有限公司

Plastic product used for children toy

InactiveCN107383735AImprove wear resistance and heat resistanceEnhance flexibility and elasticityBenzeneHardness

The invention discloses a plastic product used for a children toy. The plastic product is composed of acrylonitrile, butadiene, a benzene polymer, surface-modified carbon fiber, a colouring agent and a fixing agent according to a certain proportion, and the colouring agent is extracted from natural tomato. The acrylonitrile-butadiene-benzene polymer are taken as the main materials, the usage of acrylonitrile increases the hardness of the product and increases the wear resistance and heat resistance of the product, the usage of butadiene enhances the smoothness and elasticity of the product, and the usage of the benzene polymer keeps good moulding. The key point of the plastic product is characterized in that the colouring agent is extracted from tomato and is natural, so that influence of pigment safety due to long-time contact with the toy by children can be avoided.

Owner:南通成山高分子材料有限公司

Shoe sole production process

InactiveCN112140606AImprove uniformityImprove wear and heat resistanceDomestic footwearEmbrittlementManufacturing engineering

The invention discloses a shoe sole production process. The shoe sole production process comprises the following steps that P1, a rubber material is selected according to mass percent for later use; P2, a degreased material is obtained; P3, a mixed raw material is obtained; P4, a crushed material is formed; P5, the crushed material is put into a melting furnace again, and heating is carried out toa molten state to obtain a uniform material; P6, a shoe sole blank is obtained; P7, a finished blank is obtained; and P8, the finished blank is put into a constant-temperature chamber, heat preservation is carried out to 30 DEG C-35 DEG C, constant-temperature shaping is carried out, constant-temperature shaping lasts for 24 hours-36 hours, and production of the shoe sole can be completed. Zinc oxide powder is added to the interior of the rubber material, then secondary smashing and melting are carried out, the mixing uniformity can be effectively improved, the wear resistance and heat resistance of the shoe sole are further enhanced, hardening and embrittlement are avoided, the product quality is improved, meanwhile, by adopting a reasonable proportion, the structural performance is enhanced, the anti-aging capacity is high, the production is facilitated, and the popularization and the use are convenient.

Owner:瑞安市匡泰鞋业有限公司

High-conductivity copper alloy rotor and preparation method thereof

ActiveCN111500891AImprove conductivityExcellent high temperature hardnessAsynchronous induction motorsManufacturing cage rotorsMischmetalManganese

The invention discloses a high-conductivity copper alloy rotor and a preparation method thereof. The high-conductivity copper alloy rotor is prepared from the raw materials in percentage by weight: 0.1-2% of chromium, 0.1-0.6% of zirconium, 0.02-0.03% of lithium, 0.02-0.03% of manganese, 0.01-0.05% of rare earth metals, and the balance of copper. The invention also discloses a preparation method for the high-conductivity copper alloy rotor. The preparation method has a simple process and can reduce production costs. The obtained high-conductivity copper alloy rotor has good electrical conductivity, high-temperature hardness and stability, fully meets the requirements of use, prolongs the service life, and effectively solves the problems of poor electrical conductivity, easy wear and shortservice life in the prior art.

Owner:四川华芯腾科技有限责任公司

A method for improving the wear resistance and heat resistance of steel

ActiveCN107893192BImprove wear and heat resistanceImprove antioxidant capacityRare-earth elementSmelting process

Owner:马鞍山市恒特重工科技有限公司

A kind of non-stick pan coating with graphene material and preparation method thereof

ActiveCN110358442BSensitive over-temperature reminder effectReversible over-temperature reminder effectFireproof paintsCooking-vessel materialsModified carbonDioxyethylene Ether

The invention discloses a non-stick pan coating with graphene material. The non-stick pan coating is composed of a bottom layer and a surface layer; the bottom layer is composed of the following parts by weight of raw materials: 50-90 parts of polytetrafluoroethylene Ethylene / polysulfone blend, 0.5-2 parts modified graphene oxide, 1-5 parts thermochromic pigments, 0.8-1.2 parts modified silicon carbide whiskers, 1.5-3 parts additives and 15-35 parts deionized water; the surface layer is composed of the following raw materials in parts by weight: 35-75 parts of polytetrafluoroethylene resin, 1.5-5 parts of modified calcium carbonate whiskers, 3-8 parts of fatty alcohol polyoxyethylene ether ammonium sulfate, 5 parts of ~10 parts maleic anhydride and 35-60 parts deionized water. Through the reasonable compatibility of different raw material components of the bottom layer and the surface layer, the prepared non-stick pan coating has a better over-temperature prompting function, is more conducive to the control of the cooking temperature, and has excellent high temperature resistance and wear resistance. Extends the life of non-stick pans.

Owner:NINGBO GOLDEN ELEPHANT KITCHENWARE CO LTD

Composite material capable of improving abrasion resistance and heat resistance of steel casting and production technology

InactiveCN108941436AImprove wear and heat resistanceImprove wear resistanceFoundry mouldsFoundry coresOlivineAluminium

The invention discloses a composite material capable of improving abrasion resistance and heat resistance of a steel casting and a production technology. The composite material includes siliceous sand, bauxite, kyanite, rutile and zircon sand, magnesia and olivine. The granularity of the siliceous sand, the granularity of the bauxite, the granularity of the kyanite, the granularity of the rutile and zircon sand, the granularity of the magnesia and the granularity of the olivine all range from 0.212mm to 10mm. According to the composite material capable of improving the abrasion resistance andheat resistance of the steel casting and the production technology, abrasion resistant particles are added into cast steel, and the abrasion resistance of the casting is improved; when the composite material is used on the surface of a product, the tenacity of the whole product can also be improved; and no heat treatment operation is required in the course of working. Compared with a traditional composite material and a production technology, the composite material capable of improving the abrasion resistance and heat resistance of the steel casting and the production technology have the advantages that production cost is lower and mass popularization can be facilitated. Production cycle can be shortened to a great extent, and no residual sand can be bonded on the surface of the casting easily. Due to the fact that molten iron makes contact with the sand, cooling speed is high, white ironing is facilitated, and the hardness of the product is further improved. Meanwhile, the using amount of the molten iron is decreased and production cost is reduced.

Owner:王会智

Wind turbine stator core

InactiveCN106655663BImprove wear resistanceImprove wear and heat resistanceManufacturing dynamo-electric machinesAdhesiveEngineering

The invention belongs to the technical field of generator manufacturing, and discloses a stator core of a wind generator. The stator core of the wind generator is prepared by the following processes of stacking an iron-based amorphous alloy material into a preformed part, heating the preformed part to 600 DEG C, carrying out heat preservation for 90 minutes, cooling the preformed part to a room temperature and dipping the preformed part into an adhesive; and heating the adhesive to 90 DEG C, carrying out heat preservation for 6 hours and taking out the preformed part. The stator core has abrasive resistance, low energy consumption and loss and a good application prospect.

Owner:LINYI UNIVERSITY

A kind of hot-melting high wear-resistant and anti-pollution white traffic marking material and preparation method thereof

The invention discloses a hot-melt high wear-resistant and anti-pollution white traffic marking material and a preparation method thereof, which are used for making traffic marking materials in the field of traffic technology 。 Including the following components: petroleum resin, modified rosin resin, di-n-butyl phthalate, titanium dioxide, glass microspheres, sodium distyrene biphenyl disulfonate, ethylene vinyl acetate copolymer, microcrystalline paraffin, refined white Mineral oil, quartz sand, quartz powder. The traffic marking material prepared by the invention can not only improve the wear resistance and anti-pollution ability of the traffic marking, but also enhance the adhesion of the traffic marking.

Owner:BAODING VICTORY TRAFFIC FACILITIES ENG CO LTD

Wear-resistant heat-resistant high-transparency anti-dazzle glass coating

InactiveCN105860690AImprove wear and heat resistanceGood light transmissionFireproof paintsVanadium dioxideALUMINUM STEARATES

The invention discloses a wear-resistant heat-resistant high-transparency anti-dazzle glass coating. The wear-resistant heat-resistant high-transparency anti-dazzle glass coating comprises fluorocarbon resin, alcohol-soluble acrylic resin, melamino-formaldehyde resin, modified vanadium dioxide, methacryloxy propyl trimethoxyl silane, nano antimony tin oxide, polysiloxane prepolymer, styrene, o-phenylenediamine, acetylacetone, acrylate, nanometer titanium dioxide, nanosilicon dioxide, aluminum stearate, n-butyl acetate, sodium dodecyl benzene sulfonate, diphenyl ketone, leveling agents, defoaming agents BYK-330, dispersing agents DP-518, thickening agents AT-70 and stabilizing agents. The wear-resistant heat-resistant high-transparency anti-dazzle glass coating is good in light transparency and highly resistant to wear and heat.

Owner:ANHUI HERUN SPECIAL GLASS CO LTD

Wear-resistant and heat-resistant mottled cast iron material and preparation method thereof

The invention provides a wear-resistant and heat-resistant mottled cast iron material and a preparation method thereof. The wear-resistant and heat-resistant mottled cast iron material has good performance; and the preparation method is simple in process, low in production cost and suitable for industrial production. Mottled cast iron is utilized as a substrate for the wear-resistant and heat-resistant mottled cast iron material, wherein metal wire clusters formed by iron wires are distributed in the substrate; the diameter of the iron wires is 0.2-2mm; the diameter of the metal wire clustersis 10-15cm; and the iron wires account for 5-40% of the material by volume.

Owner:金湖中博物联网科技有限公司

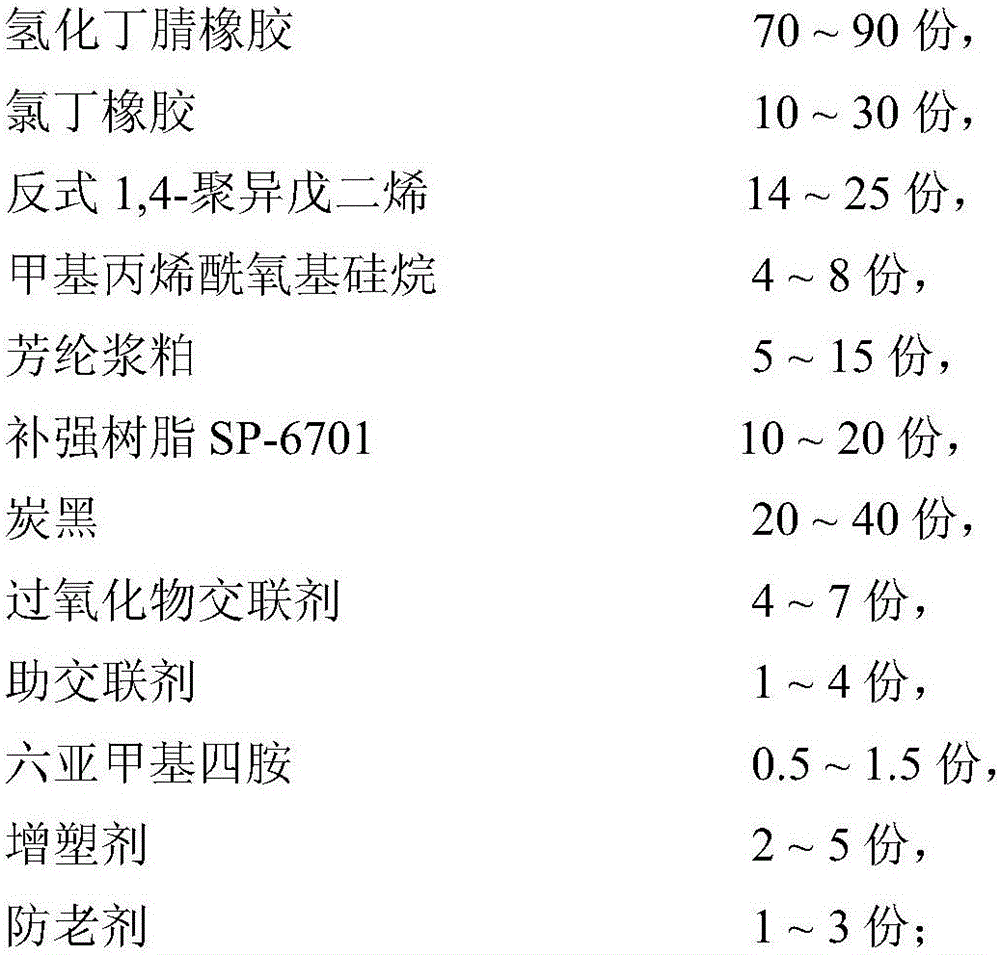

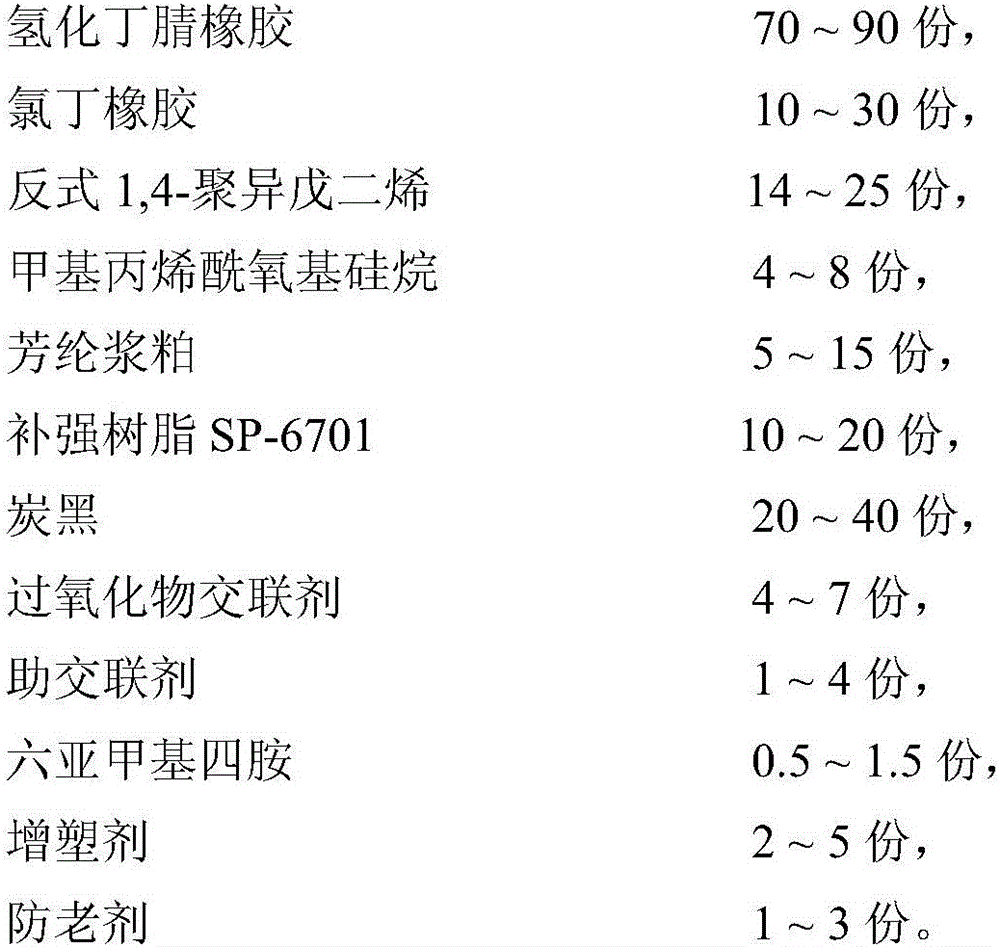

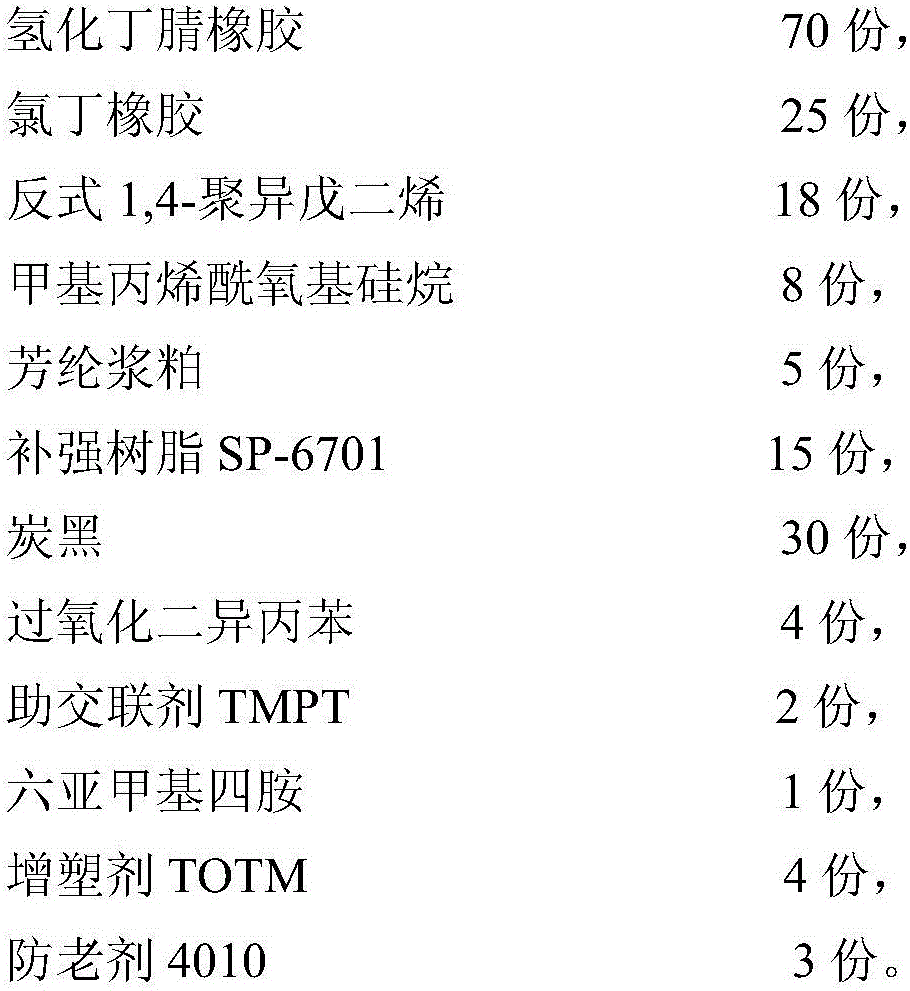

A high-strength synchronous belt and its preparation method

ActiveCN104675922BImprove wear resistanceImprove heat resistanceDriving beltsMonocomponent synthetic polymer artificial filamentSilanesAcrylonitrile

The invention relates to a high-strength synchronous belt. The synchronous belt comprises a synchronous belt framework and an adhesive piece attached to the outer side of the synchronous belt frame. The adhesive piece comprises the following components in parts by weight: 70-90 parts of hydrogenated butadiene-acrylonitrile rubber, 10-30 parts of chloroprene rubber, 14-25 parts of trans 1, 4-polyisoprene, 4-8 parts of methylacryloyl silane, 5-15 parts of aramid pulp, 10-20 parts of reinforced fiber SP-6701, 20-40 parts of carbon black, 4-7 parts of peroxide crosslinking agent, 1-4 parts of assistant crosslinking agent, 0.5-1.5 parts of hexamine, 2-5 parts of plasticizer and 1-3 parts of antiaging agent. The invention also relates to a manufacturing method of the synchronous belt. According to the high-strength synchronous belt and the manufacturing method thereof, the hydrogenated butadiene-acrylonitrile rubber and the chloroprene rubber are used together, so that the performances of the hydrogenated butadiene-acrylonitrile rubber and the chloroprene rubber are complementary, and thus the wear resistance and the heat resistance of the adhesive piece of the synchronous belt can be effectively improved; the shear strength and the quality stability of the synchronous belt are improved by use of the trans 1, 4-polyisoprene, the methylacryloyl silane and the aramid pulp.

Owner:NINGBO FULONG SYNCHRONOUS BELT

Method for improving wear resistance and heat resistance of steel

ActiveCN107893192AImprove wear and heat resistanceImprove antioxidant capacityRare-earth elementManganese

The invention relates to the technical field of mechanical steel machining, and discloses a method for improving wear resistance and heat resistance of steel. The multi-element alloying method is mainly utilized, manganese, nitrogen and the like are used for replacing nickel, the nickel content is reduced, and meanwhile rare earth elements are added; the affinity of the alloy elements with carbonand nitrogen is quite high, carbide and nitride particles which are distributed in a highly dispersed manner and are extremely high in hardness are formed in the alloy smelting process, the stabilityof the particles is quite high, and the particles cannot be completely dissolved even at the temperature of 1,300 DEG C; and the surface treatment technology is further adopted, oxidation resistance of the steel is improved, the highest heat resisting temperature of the heat resisting steel is improved to 1,200 DEG C-1,300 DEG C from original 900 DEG C-1,000 DEG C, and therefore the application field of the heat resisting steel is greatly expanded.

Owner:马鞍山市恒特重工科技有限公司

Preparation method of graphene heating plate

PendingCN114501704AImprove wear and heat resistanceIncrease life timeHeating element materialsHeat resistanceGraphite

The invention relates to the technical field of graphene heating plate preparation, in particular to a graphene heating plate preparation method which comprises the steps that a cement foaming plate is selected as a panel base material, fire-resistant and wear-resistant coatings are attached to the front end and the rear end of the cement foaming plate through a film covering device, and then the rear portion of the cement foaming panel is fixedly connected with a metal heat dissipation plate through screws; the rear end of the metal heat dissipation plate is sprayed with a graphene heating layer, the rear end of the graphene heating layer is provided with an electrode plate, finally, the outer side of the graphene heating layer and the outer side of the electrode plate are sequentially wrapped with an insulating layer, a lower light film and a PCB heat insulation film from inside to outside, and the outer side of the PCB heat insulation film is sleeved with a PC / ABS alloy shell. The fireproof and wear-resistant layer is matched with the cement foaming plate to isolate most of heat, so that the heat dissipation plate can only feel slight heat on the surface in the use process, meanwhile, the wear-resistant and heat-resistant performance is high, most of heat in the device is dissipated through the ventilation grooves, and use is safer and more stable.

Owner:FUJIAN DE RUI XIN CAI CO LTD

A hot-melt high wear-resistant and anti-pollution yellow traffic marking material and its preparation method

ActiveCN103980747BNo color changeGood weather resistanceCoatingsMicrocrystalline waxDi n butyl phthalate

Owner:BAODING VICTORY TRAFFIC FACILITIES ENG CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com