Modified POM copolymer resin and preparation process thereof

A technology of copolymer resin and preparation process, which is applied in the field of modified POM copolymer resin and its preparation technology, can solve the problems of poor thermal stability of polyoxymethylene, instability of hemiacetal end groups, and accelerated decomposition of polyoxymethylene, so as to improve Impact strength and flexibility, stable mechanical properties, and the effect of improving crystallinity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

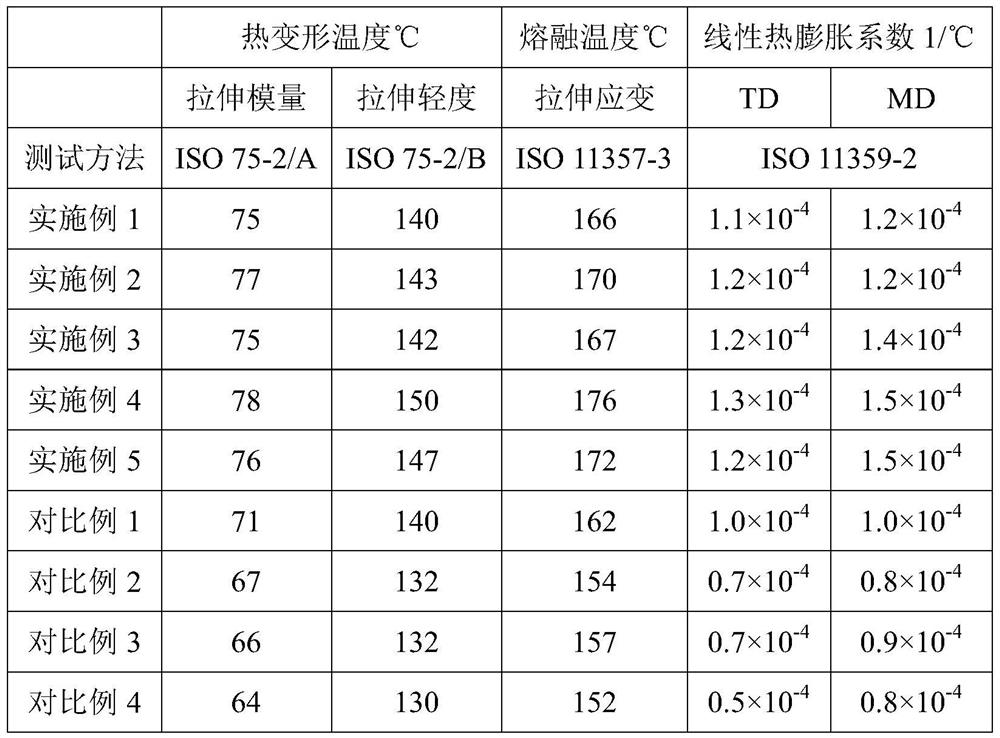

Examples

Embodiment 1

[0027] A kind of modified POM copolymer resin and preparation technology thereof:

[0028] 1) Melt and mix 25% polyoxymethylene homo, 45% polyoxymethylene copolymer, 3% composite nucleating agent, and 8% styrene-butadiene rubber particles at a temperature of 165°C, and add KH550 coupling agent (10% of the rubber particles) , stir evenly;

[0029] The composite nucleating agent is synthesized by nano-silica, melamine formal, and polyamide in a ratio of 1:1:1;

[0030] 2) Add 12% fiber filler (carbon fiber, aramid staple fiber and glass fiber 2:1:1) and 7% stabilizer zinc oxide to the molten mixture, the screw speed is 100 rpm, and the barrel temperature is 190°C Melt kneading and granulation under the conditions.

Embodiment 2

[0032] A kind of modified POM copolymer resin and its preparation process

[0033] 1) Melt and mix 28% homopolyoxymethylene, 50% polyoxymethylene, 2% composite nucleating agent, and 5% butyl rubber particles at a temperature of 170°C, and add KH560 coupling agent (10% of the rubber particles) , stir evenly;

[0034] Described composite nucleating agent is that nano-calcium carbonate, polyamide and carbon nanotube are synthesized with 1:1:2 ratio;

[0035] 2) Add 10% fiber filler (carbon fiber, aramid short fiber and glass fiber 2:1:1) and 5% stabilizer zinc oxide to the molten mixture, the screw speed is 200 rpm, and the barrel temperature is 195°C Melt kneading and granulation under the conditions.

Embodiment 3

[0037] A kind of modified POM copolymer resin and its preparation process

[0038] 1) Melt and mix 30% polyoxymethylene homo, 36% polyoxymethylene copolymer, 3% composite nucleating agent, and 10% butadiene rubber particles at a temperature of 175°C, and add KH570 coupling agent (10% of the rubber particles) , stir evenly;

[0039] Described composite nucleating agent is that nano-calcium carbonate, melamine formal, carbon nanotube are synthesized with 1:1:2 ratio;

[0040] 2) Add 11% fiber filler (carbon fiber, aramid short fiber and glass fiber 3:1:1) and 10% stabilizer zinc oxide to the molten mixture, the screw speed is 200 rpm, and the barrel temperature is 200°C Melt kneading and granulation under the conditions.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com