Tape for electric wire

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

[0031]a tape of the present invention for an electric wire is described below.

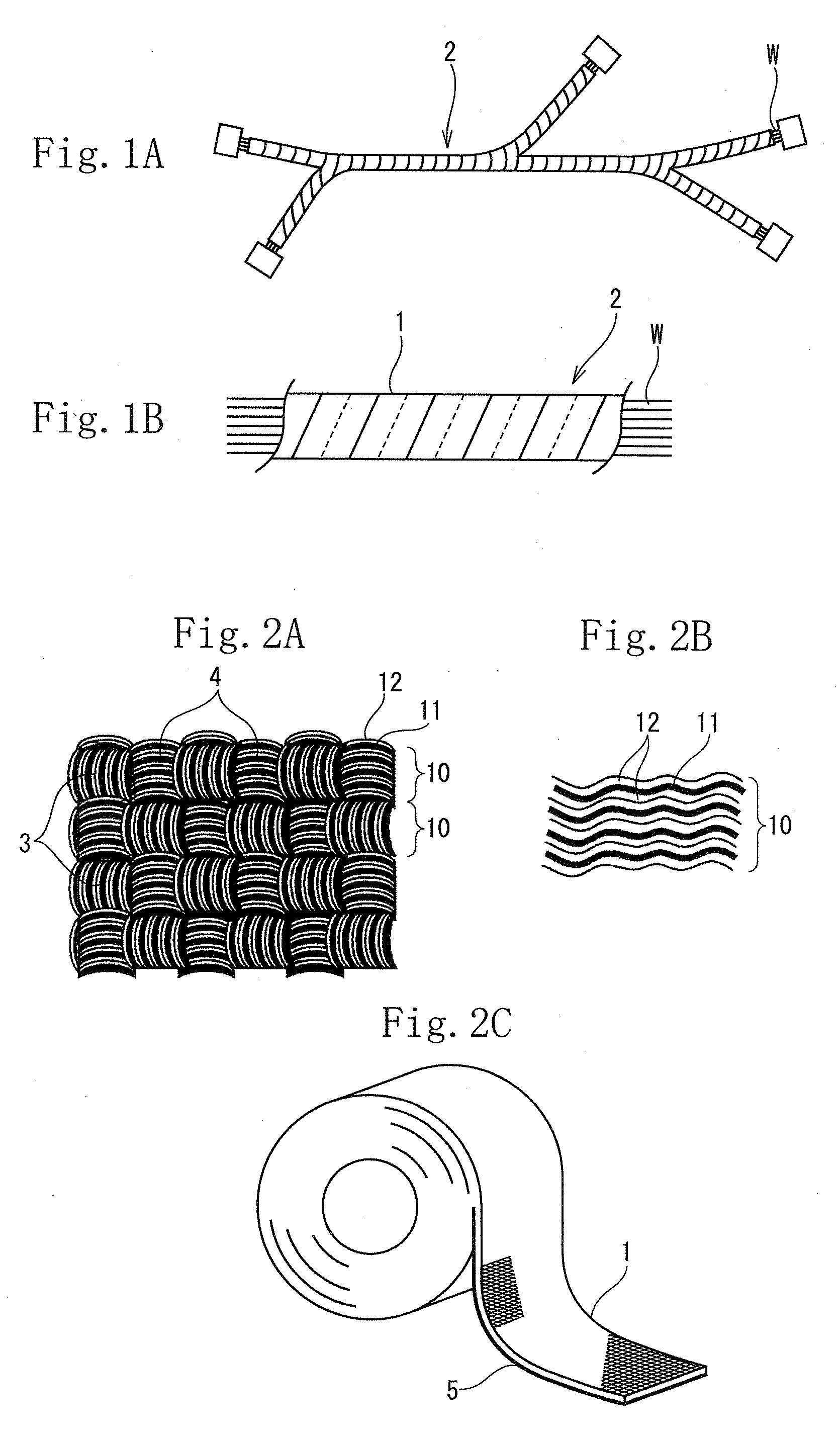

[0032]As shown in FIG. 1(A), a tape 1 of the present invention for electric wires is used to bind the electric wires by spirally winding it around a peripheral surface of a wire harness 2, consisting of a group W of electric wires, which is to be wired on a car by means of half-wrap winding of overlapping the half of the width of a portion of the tape 1 to be wound on a wound portion thereof or wide-pitch winding as shown in FIG. 1(B). The tape 1 can be also used for partial winding of partially winding it around the group of the electric wires in the longitudinal direction thereof. The tape 1 is used for portions where conventional general-purpose tapes for electric wires are used.

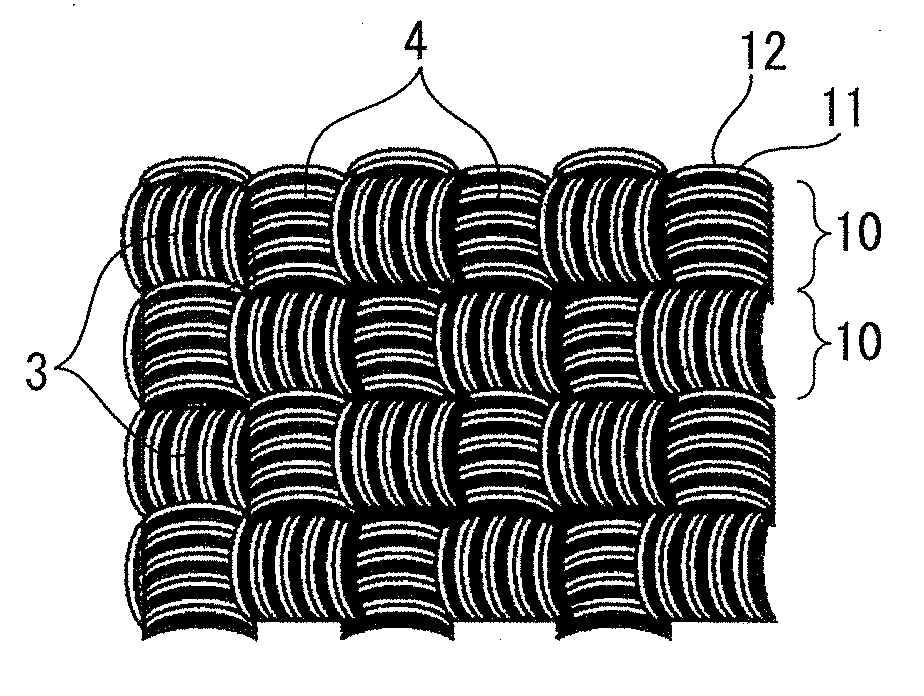

[0033]As shown in FIG. 2(A) which is an enlarged view of the tape 1, the tape 1 consists of a cloth tape formed by weaving warps 3 and wefts 4. As shown in FIG. 2 (C) which is a schematic perspective view, an adhesive agent 5 is...

second embodiment

[0047]The second embodiment is described below.

[0048]A tape of the second embodiment formed by weaving the warps and the wefts is irradiated with ionizing radiation to crosslink the general-purpose fiber strands consisting of the polyester fiber to allow the tape of the second embodiment to have a heat resistance higher than that of the tape 1 of the first embodiment and a melting temperature at 120° C.

[0049]The polyester fiber strand to be used as the general-purpose fiber strand is composed of a kneaded material containing polyester and 1 to 3 parts by weight of a crosslinking monomer consisting of triallyl isocyanurate or triallyl cyanurate added to 100 parts by mass of the polyester.

[0050]Yarns consisting of the general-purpose fiber strands and the high-function fiber strands similar to that of the first embodiment are woven by using the yarns as warps and wefts.

[0051]After the tape is formed by weaving the yarns, the tape is irradiated with the ionizing radiation having 100 kG...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fraction | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com