Composite asphalt modifier

An asphalt modifier and composite technology, which is applied in building components, building insulation materials, buildings, etc., can solve the problems of easy segregation of matrix asphalt, restrictions on widespread application and complex modification process, etc., and achieves good feasibility and efficiency. The effect of promotion, low price and wide source of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] The ratio of each raw material in the main material and auxiliary material, and the compounding ratio of the main material and auxiliary material can be determined through experiments according to the needs of customers.

[0020] As a further illustration, the ratio of each raw material in the main material and the auxiliary material, the compounding ratio of the main material and the auxiliary material are determined according to the customer's needs through experiments, and then the main material and the auxiliary material are evenly mixed, and then the product can be obtained by sub-packaging.

[0021] The main material is 800g of diatomite, 400g of clay ore, 400g of bentonite, a total of 1600g; the auxiliary materials are 200g of coal tar pitch, 200g of natural asphalt, a total of 400g, and a total of 2000g of main materials + auxiliary materials. Type asphalt modifier 2000g.

[0022] Take 8.8kg of No. 90 A-grade heavy-duty petroleum asphalt, heat it to 160°C, add 1...

Embodiment 2

[0027] The main material is 700g of diatomite, 400g of clay ore, 400g of bentonite, 1500g in total; the auxiliary materials are 300g of petroleum asphalt, 100g of rubber powder, 100g of mica powder, 500g in total, and the total of main material + auxiliary material is 2000g. After fully mixing, it is made A composite asphalt modifier 2000g.

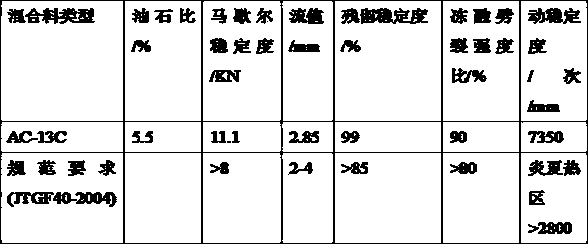

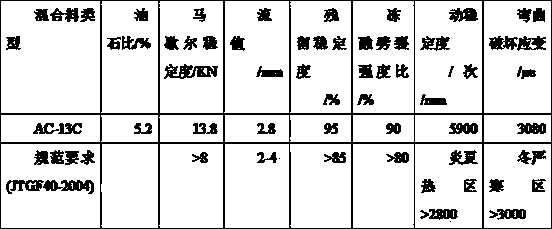

[0028] Take 8.8kg of No. 90 A-grade heavy-duty petroleum asphalt, heat it to 160°C, add 1.2kg of the mixed asphalt modifier prepared above, and stir for 50 minutes to obtain 10kg of modified asphalt, and make AC according to the asphalt ratio of 5.5%. -13C composite modified asphalt mixture, the measured technical performance indicators are shown in Table 2.

[0029]

[0030] Table 2 The test results of various technical performance indicators of the composite modified asphalt mixture in the example

[0031]

[0032] It can be seen from Table 2 that all indicators are higher than the requirements of the current specification (JTGF40-...

Embodiment 3

[0034] The main material is 800g of diatomite, 400g of dickite, 350g of bentonite, a total of 1550g; the auxiliary materials are 250g of coal tar pitch, 200g of rubber powder, a total of 450g, and the total of main materials + auxiliary materials is 2000g. Composite asphalt modifier 2000g.

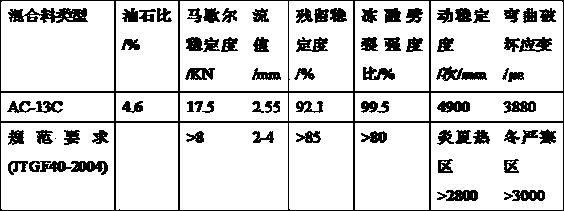

[0035] Take 8.8kg of AH-70 grade heavy-duty petroleum asphalt, heat it to 160°C, add 1.2kg of the mixed asphalt modifier prepared above, and stir for 20 minutes to obtain 10kg of modified asphalt, and make AC according to the asphalt ratio of 4.6%. -16C composite modified asphalt mixture, the measured technical performance indicators are shown in Table 3.

[0036]

[0037] Table 3 Test results of various technical performance indicators of the composite modified asphalt mixture of the example

[0038]

[0039] It can be seen from Table 3 that all indicators are higher than the requirements of the current specification (JTGF40-2004), indicating that the modification status is good.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com