Vehicle high-loading-resistance steering gear bushing rubber material and preparation method thereof

A technology of rubber materials and steering gears, which is applied in the field of high-load-resistant steering gear bushing rubber materials for automobiles and its preparation, and can solve the problems of smaller design of steering gear bushings, inability to meet high load and durability requirements of steering gears, etc. , to achieve the effect of solving stickiness and cracking, excellent wear resistance and durability, and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

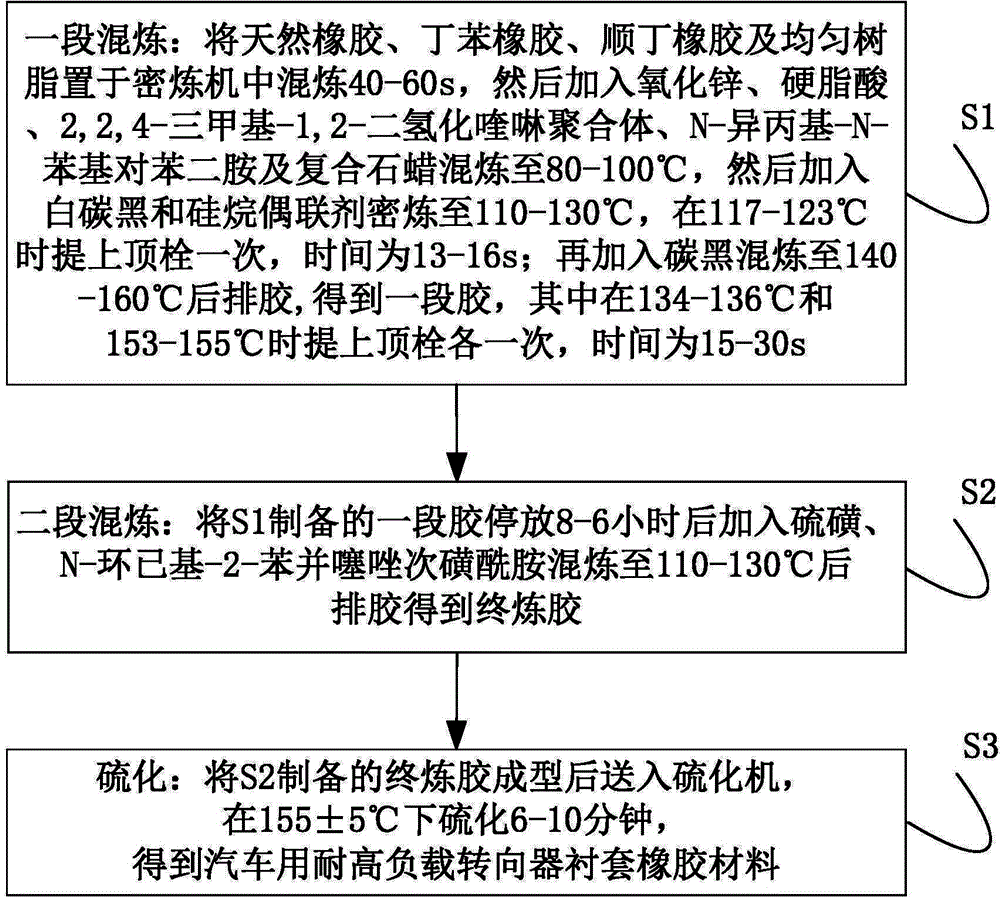

[0023] refer to figure 1 , a kind of preparation method of high-load resistant steering gear bushing rubber material for automobiles, comprising the steps of:

[0024] S1. One-stage mixing: put natural rubber, styrene-butadiene rubber, butadiene rubber and homogeneous resin in an internal mixer and knead for 40-60s, then add zinc oxide, stearic acid, 2,2,4-trimethyl -1,2-dihydroquinoline polymer, N-isopropyl-N-phenyl-p-phenylenediamine and compound paraffin are mixed to 80-100 ° C, then white carbon black and silane coupling agent are added to banbury to 110-130°C, where the top bolt is lifted once at 117-123°C, and the time is 13-16s; then add carbon black and mix to 140-160°C and then discharge the glue to obtain a section of glue, which is at 134-136°C and At 153-155°C, lift the top bolt once for 15-30s;

[0025] S2, two-stage mixing: park the first-stage rubber prepared in S1 for 8-16 hours, add sulfur, N-cyclohexyl-2-benzothiazole sulfenamide and mix to 110-130°C, then ...

Embodiment 1

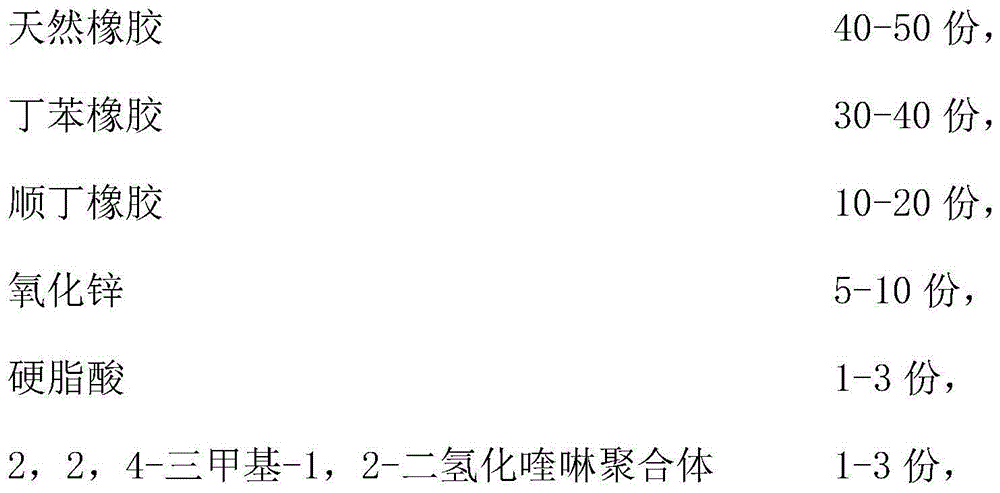

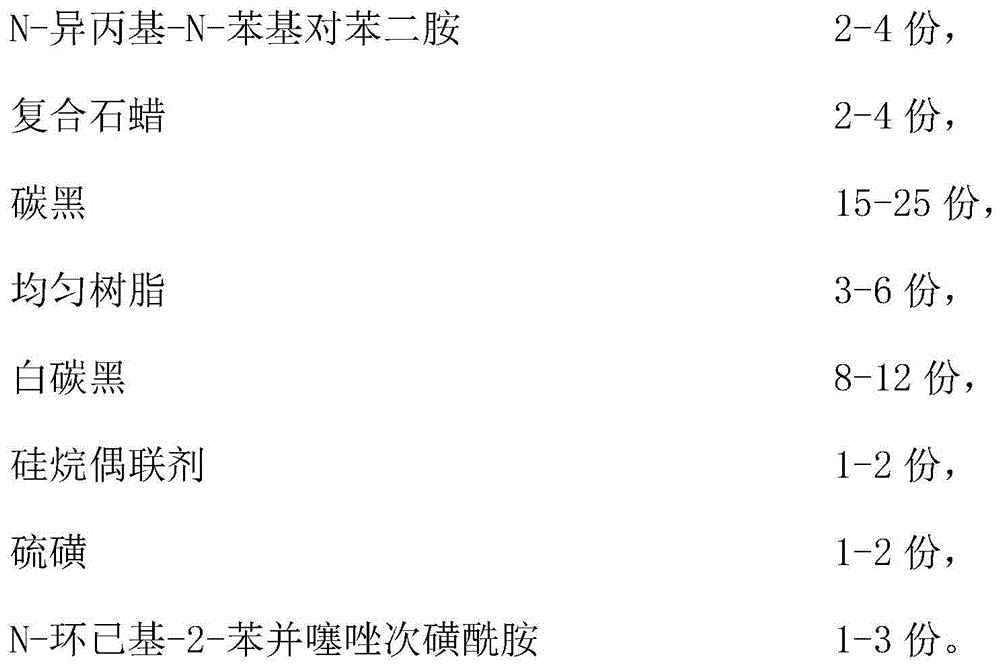

[0028] The high-load-resistant steering gear bushing rubber material for automobiles proposed in this embodiment 1, its raw materials include by weight:

[0029]

[0030]

[0031] The preparation method of the above-mentioned high-load-resistant steering gear bushing rubber material for automobiles comprises the following steps:

[0032] S1, one-stage mixing: put natural rubber SMR5, styrene-butadiene rubber, butadiene rubber BR9000 and uniform resin 40MSF in the internal mixer and mix for 50s, then add zinc oxide, stearic acid, 2,2,4-trimethyl Base-1,2-dihydroquinoline polymer, N-isopropyl-N-phenyl-p-phenylenediamine and compound paraffin OK1987 were mixed to 90°C, then added precipitation white carbon black 175GR and silane coupling agent Logsil4C is mixed to 125°C, and the top bolt is lifted once at 120°C for 15s; then carbon black N-220 is added and mixed to 160°C, and then the glue is removed to obtain a section of glue, in which at 135°C and 155°C Lift the top bol...

Embodiment 2

[0036] The high-load-resistant steering gear bushing rubber material for automobiles that present embodiment 2 proposes, its raw materials include by weight:

[0037]

[0038]

[0039] The preparation method of the above-mentioned high-load-resistant steering gear bushing rubber material for automobiles comprises the following steps:

[0040] S1, one-stage mixing: put natural rubber, styrene-butadiene rubber, butadiene rubber and homogeneous resin in an internal mixer and knead for 40 seconds, then add zinc oxide, stearic acid, 2,2,4-trimethyl-1 , 2-dihydroquinoline polymer, N-isopropyl-N-phenyl-p-phenylenediamine and compound paraffin are mixed to 100°C, then white carbon black and silane coupling agent are added to banbury to 125°C, of which Lift the top bolt once at 120°C for 13s; then add carbon black and mix to 155°C and discharge the glue to obtain a section of glue, in which the top bolt is lifted once at 134°C and 152°C for 30s;

[0041] S2. Second-stage mixin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com