High-flame-retardance temperature preservation plate and preparation method thereof

A thermal insulation board, high flame retardant technology, applied in thermal insulation, building components and other directions, can solve the problems of restricting the development of rigid polyurethane foam insulation board, the price of polyurethane foam materials is relatively expensive, etc., to achieve easy workshop mass production, good mechanical properties, The effect of improving the flame resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

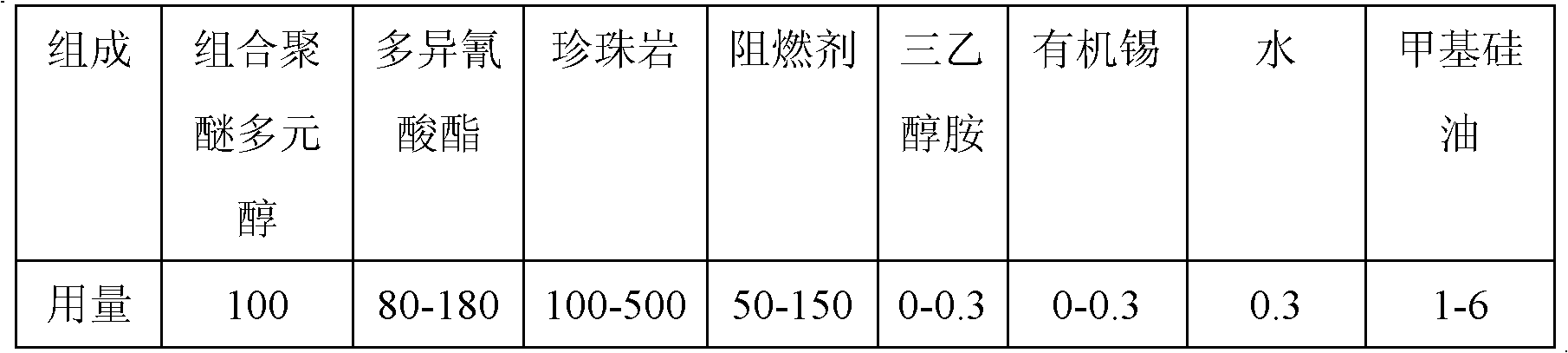

[0023] Embodiment 1 (comparative example)

[0024] According to the following formula, mix N303 polyether polyol (hydroxyl value 475±25mgKOH / g), ethylene glycol, triethanolamine, dibutyltin dilaurate, and methyl silicone oil, stir and mix well, and then add TDI , stir evenly, add water and mix evenly, then immediately pour into the mold, let it stand for 30min, put it in an oven at 120°C for 4h, and demould, and the polyurethane insulation board is obtained.

[0025]

[0026] A dense crust layer is formed on the surface of the obtained product, and the measured oxygen index is 18, the thermal conductivity is 0.021W / m K, the compressive modulus of the product is 25.884MPa, the dimensional change rate is 0.3%, and the closed cell rate is 90.4%. , The water absorption rate is 1.2%.

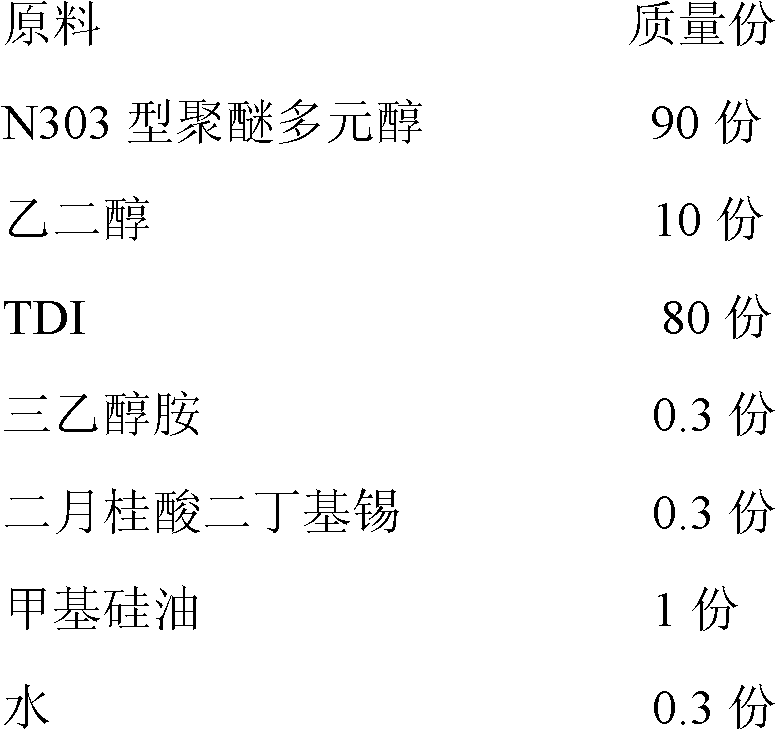

Embodiment 2

[0028] According to the following formula, N303 type polyether polyol (475±25mgKOH / g), ethylene glycol, closed-cell perlite particles with a particle size of 0.15mm, triethanolamine, dibutyltin dilaurate, methyl silicone oil, TCPP and hydroxide Mix the components of magnesium, fully stir and mix, then add MDI, stir evenly, add water and mix evenly, then immediately pour into the mold, let it stand for 30min, put it in an oven at 120°C for 4h, and demould, that is, the high-quality magnesium alloy is obtained. Flame retardant perlite filled polyurethane insulation board.

[0029]

[0030]

[0031] A dense crust layer is formed on the surface of the obtained product, and the measured oxygen index is 28.2, the thermal conductivity is 0.023W / m·K, the compressive modulus of the product is 24.975MPa, the dimensional change rate is 0.9%, and the closed cell rate is 89.76%. , The water absorption rate is 3.5%.

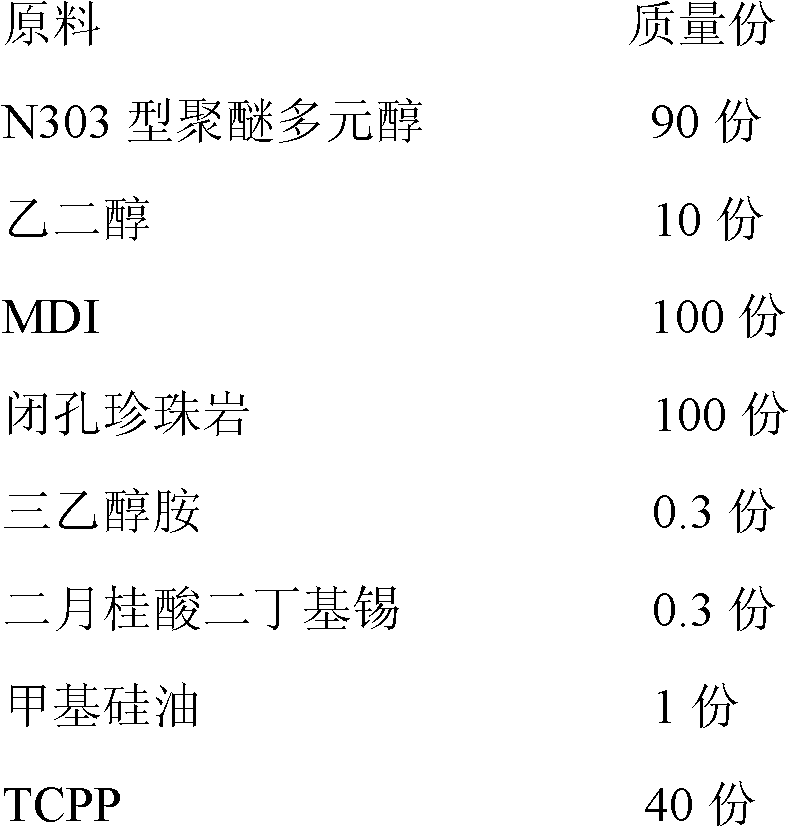

Embodiment 3

[0033] According to the following formula, N303 type polyether polyol (475±25mgKOH / g), ethylene glycol, expanded perlite particles with a particle size of 0.15mm, triethanolamine, dibutyltin dilaurate, methyl silicone oil, DMMP and magnesium hydroxide Mix the components, stir and mix them well, then add PAPI, mix them evenly, add water and mix them evenly, then pour them into the mold immediately, let it stand for 30 minutes, put it in an oven at 120°C for 4 hours, and demould, and you will get a high resistance Combustible perlite-filled polyurethane insulation panels.

[0034]

[0035] A dense crust layer is formed on the surface of the obtained product, and the measured oxygen index is 30.2, the thermal conductivity is 0.027W / m K, the compression modulus of the product is 26.742MPa, the dimensional change rate is 0.9%, and the closed cell rate is 90.21%. , The water absorption rate is 3.9%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

| compressive modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com