Processing method for UV laser incision butt-joint uncovering

A technology of laser and crossover wires, which is applied in the structural connection of printed circuits, multi-layer circuit manufacturing, printed circuit components, etc., can solve problems such as poor opening of the cover, and achieve the effect of improving production efficiency and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

[0019] A processing method for UV laser cutting butt joint opening, such as Figure 1-6 , including the following steps:

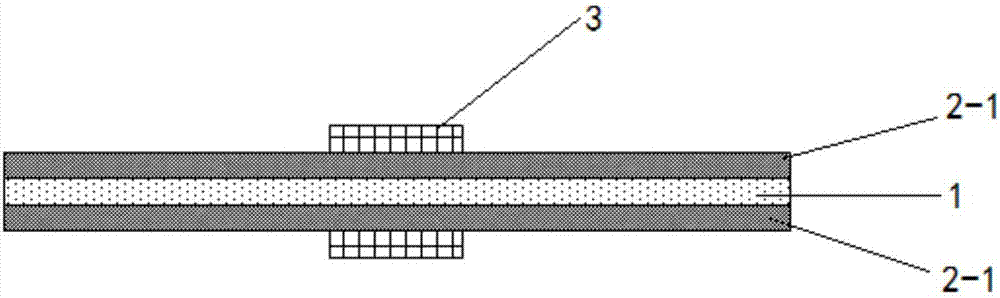

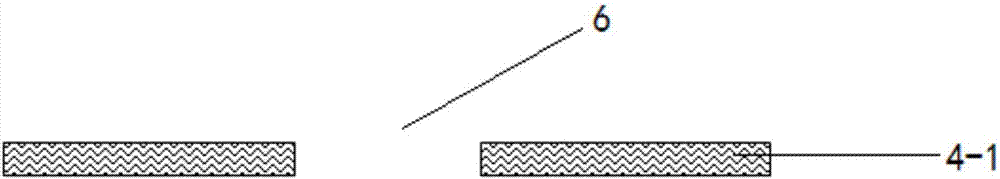

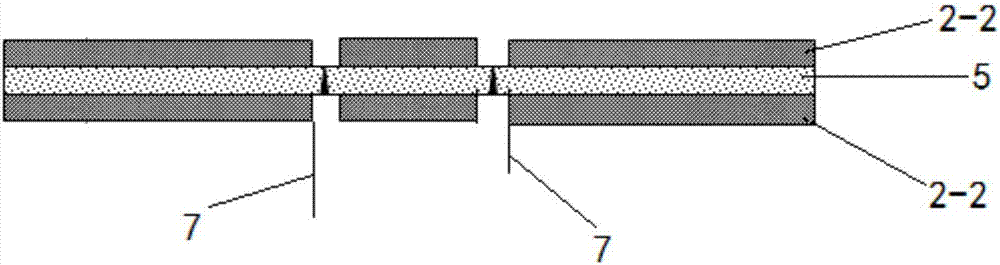

[0020] 1), such as figure 1 As shown, to make the soft board layer of the inner core board of the printed circuit soft-rigid board: evenly lay the complete first copper foil 2-1 on the top and bottom of the soft board 1; 2), stick and press on the area where the finished product needs to be bent Combine the cover film 3; 3), make the first prepreg 4-1, such as figure 2 As shown, open the window 6 design at the position of the corresponding soft area; 4) Make the hard board layer of the inner core board of the printed circuit flex-hard board: there are two hard board layers, each with a thickness of 0.15mm. The second copper foil 2-2 with windows is evenly laid on the top and bottom of the board 5 corresponding to the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com