Manufacturing method for flexible and hard combined thin PCB

A soft-hard combination and processing method technology, applied in the direction of assembling printed circuits with electrical components, can solve problems such as affecting the quality of the board, damage to the window, and inability to manufacture, and achieve the effect of improving the pass rate and simplifying the processing process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention is described in detail below in conjunction with embodiment:

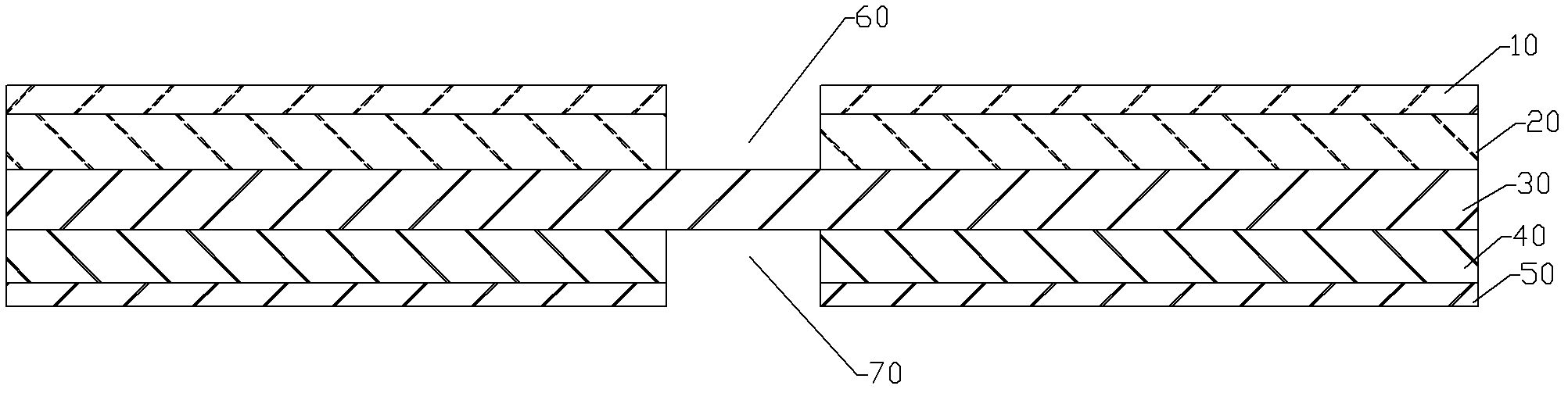

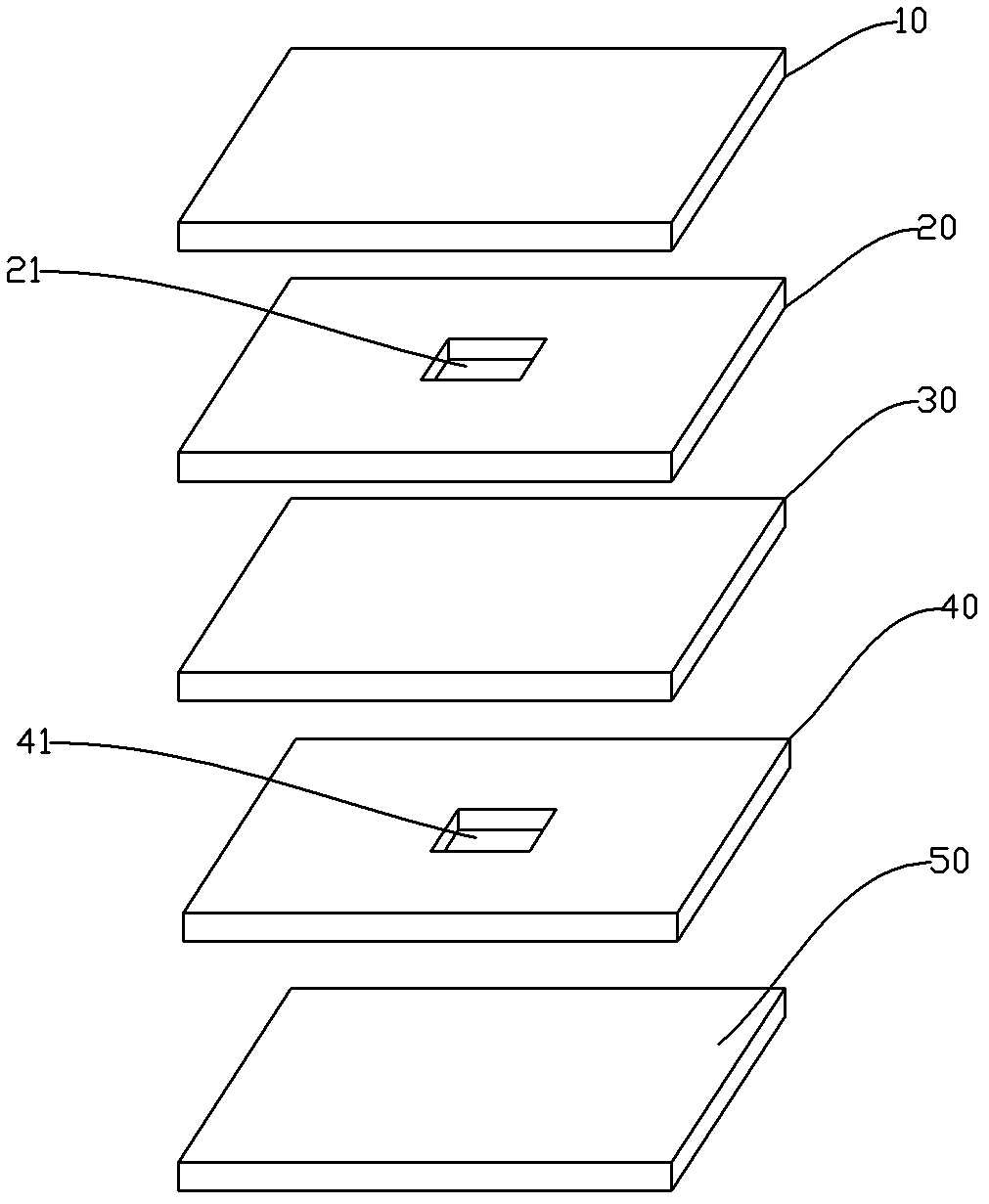

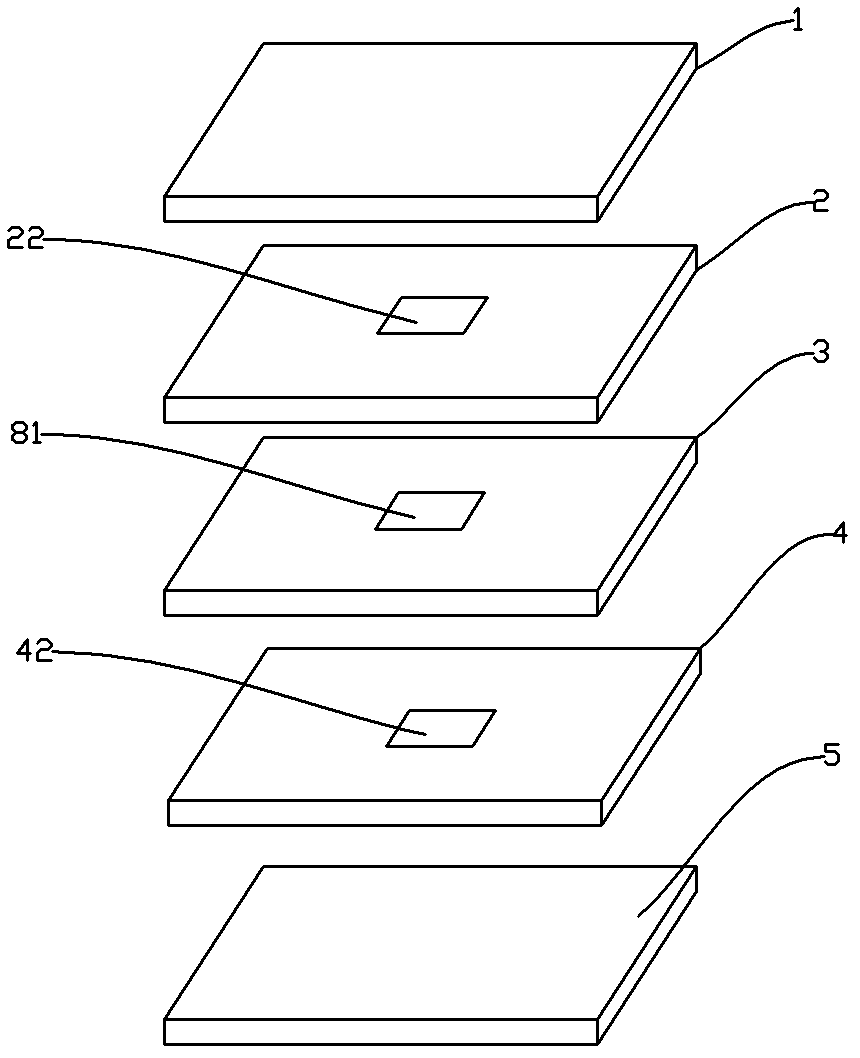

[0037] Taking the processing of a 0.2mm thick flexible and rigid PCB sheet as an example, the processing method of a flexible and rigid PCB sheet, steps a-d are as follows image 3 , Figure 4 shown.

[0038] a. Provide a soft board 3 with circuit patterns on both sides.

[0039] b. Silk-print liquid PI on the position to be protected on the upper surface of the flexible board 3 , and silk-screen print liquid PI on the position to be protected on the lower surface. The liquid PI is pre-cured by drying. A first protective film 81 is formed on the upper surface of the flexible board 3 ; a second protective film 82 is formed on the lower surface.

[0040] c. Providing the first prepreg 2 and the second prepreg 4 . Using UV laser or CO 2 The laser milling method mills through the first prepreg 2 to form the window 22 on the first prepreg 2 . Using UV laser or CO 2 The laser milling ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com