Novel rigid-flexible PCB (printed circuit board) and manufacturing method thereof

A soft-rigid combination, printed board technology, applied in printed circuit manufacturing, printed circuit, multi-layer circuit manufacturing, etc., can solve the problems of poor operability and high production cost, and achieve the effect of ensuring performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

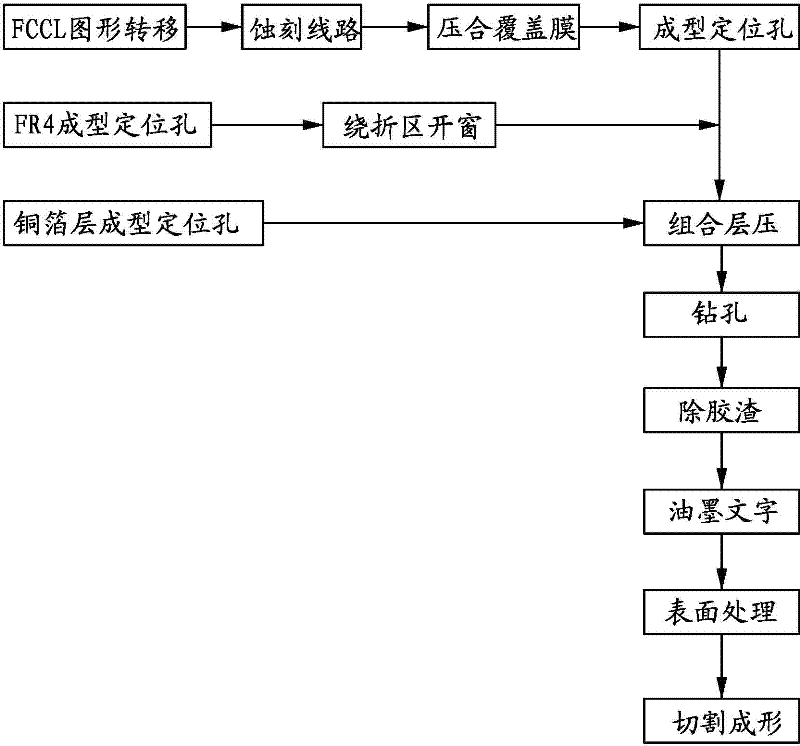

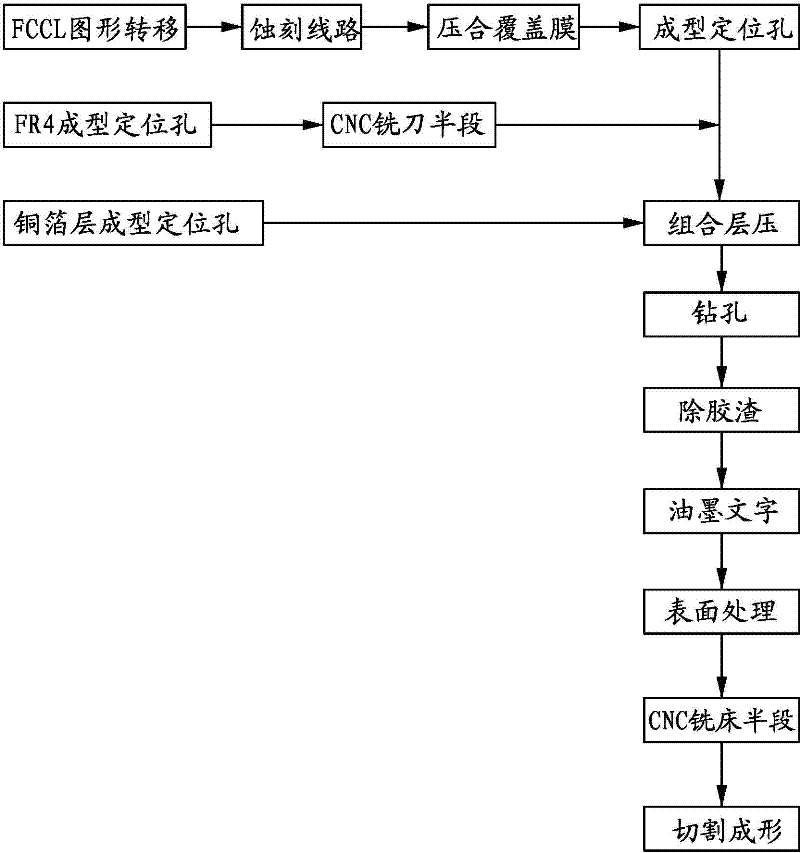

Method used

Image

Examples

Embodiment Construction

[0037] In order to further explain the technical solutions of the present invention, the present invention will be described in detail below through specific embodiments.

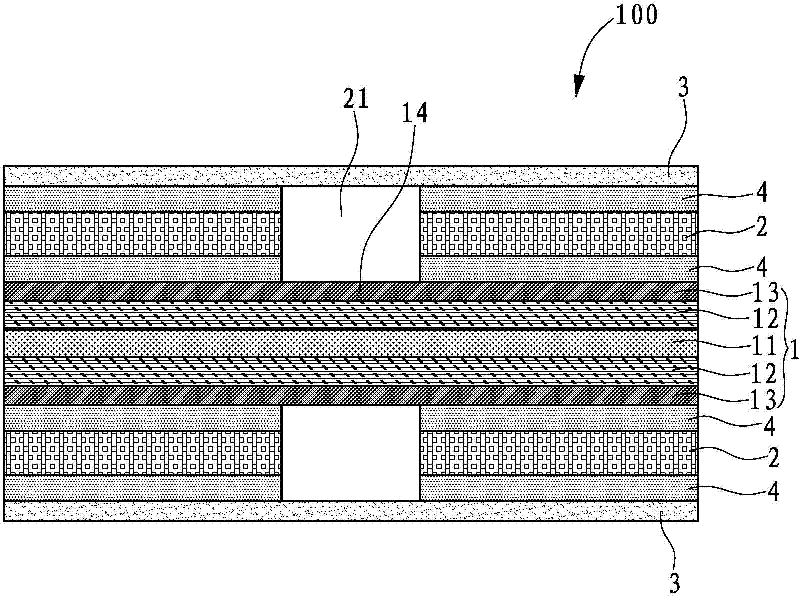

[0038] like figure 1 and figure 2 As shown, it is the first embodiment of a new type of flexible-rigid printed board 100 according to the present invention.

[0039] The FPC core board 1 is formed of FPC. Specifically, the FPC includes a FPC base material 11 and a copper foil layer 12 on both sides of the FPC base material 11 , and the copper foil layers 12 on both sides of the FPC base material 11 . A cover film 13 is formed on the outer side. In this embodiment, the PI layer is selected as the substrate 11 of the flexible board. Of course, the FPC can also be other structures in the field, and will not be described one by one.

[0040] The two pieces of hard board base material 2 are located on both sides of the soft board core board 1, and each piece of hard board base material 2 and the soft board c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com