Local-fitting hole-avoiding flex-rigid combined board and manufacturing method thereof

A technology of rigid-flex board and manufacturing method, which is applied in multilayer circuit manufacturing, printed circuit components, etc., can solve the problems of layered board explosion, product test open circuit and poor reliability of products, so as to improve the bonding force and avoid explosion board and layering, avoiding the effect of large differences in material properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

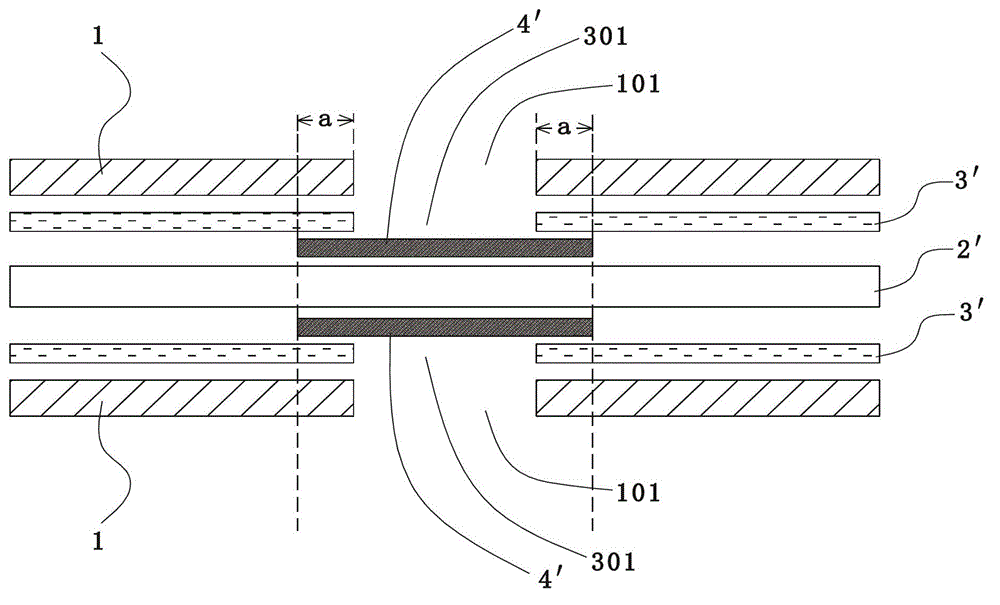

[0034] In order to illustrate the idea and purpose of the present invention, the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0035] In the present invention, the cover film, pure glue and heat-conducting double-sided adhesive are made into a shape slightly larger than that of the window, and the partial area of the window is bonded, and the other areas are pressed by the non-flowing prepreg, which improves the inter-board contact. Bonding force; at the same time, a through hole corresponding to the pressing position of the hard board is opened on the cover film, which prevents the residual glue from entering the blind hole, through hole or slot hole of the hard board, and ensures the rigid-flexible combination The electrical conduction performance of the board improves the reliability of the product.

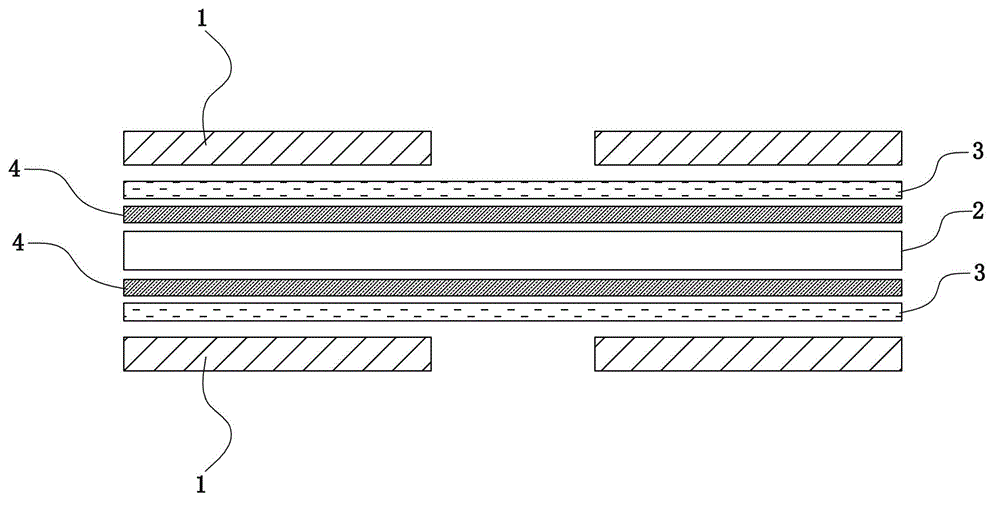

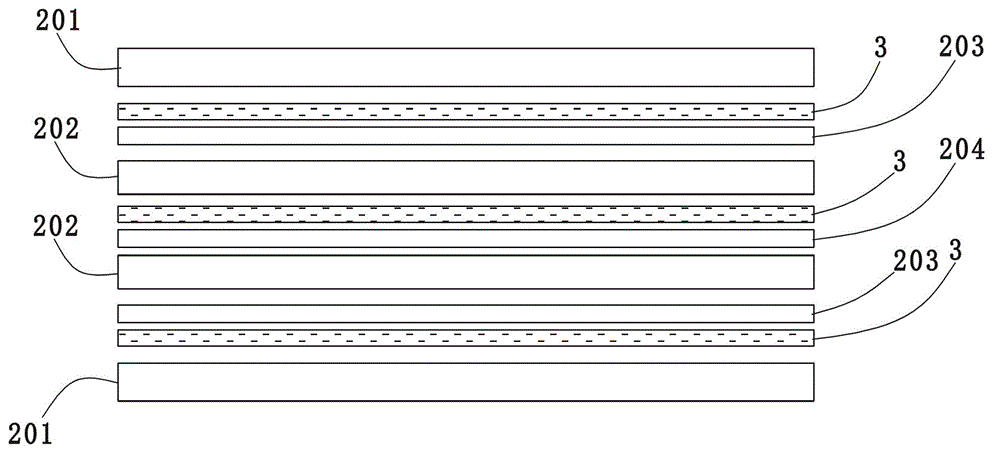

[0036] See image 3 , Figure 4 as shown, image 3 It is a schematic cross-sectional structu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com