Rigid-flex circuit board and production method thereof

A combination of soft and hard, production method technology, applied in the direction of printed circuit manufacturing, printed circuit, printed circuit assembly of electric components, etc., can solve the problems of complex processing process and operability, etc., to save processing steps, simple manufacturing process, save The effect of processing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

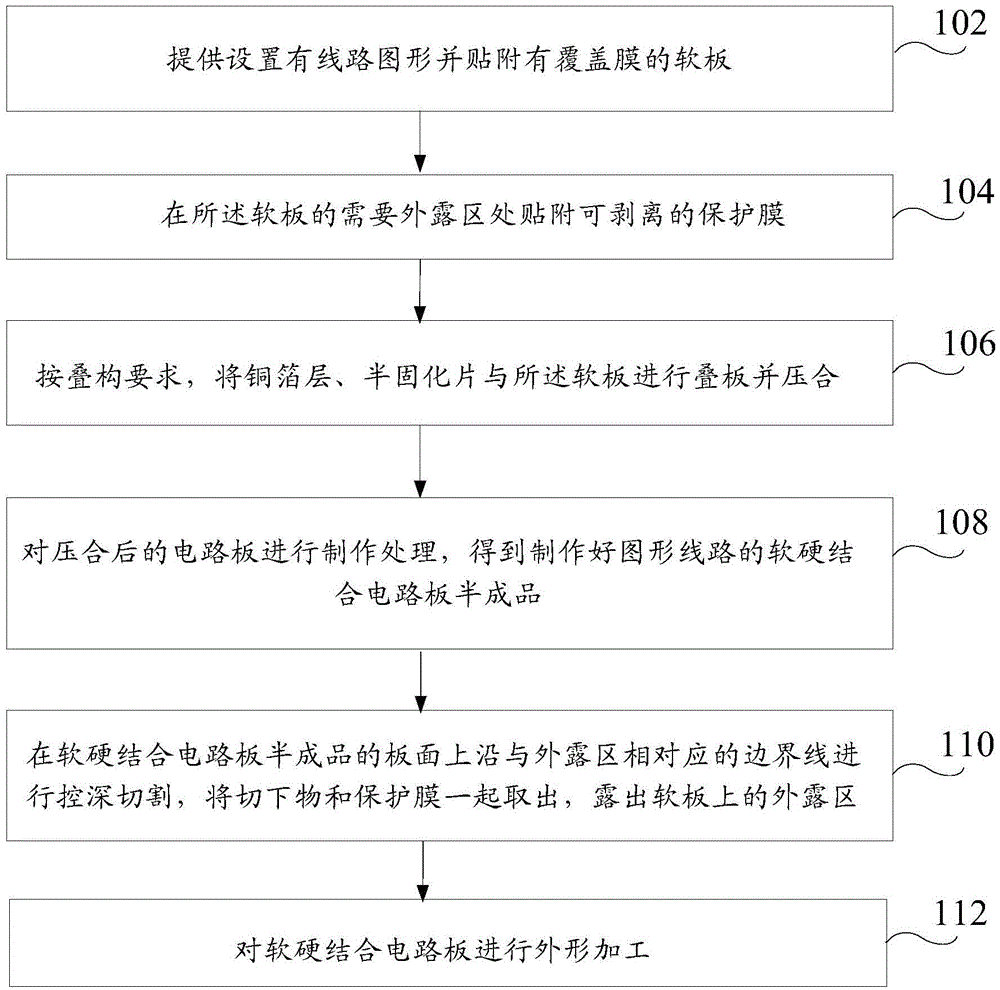

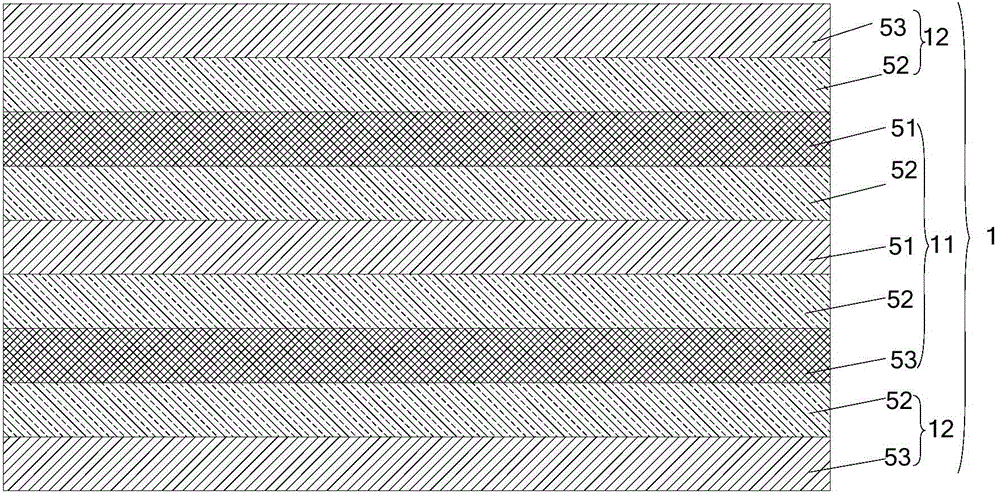

[0059] 1) Make circuit patterns on the flexible circuit substrate 11, and make alignment target holes and targets (not shown in the figure) on the flexible circuit substrate 11, and paste the cover film 12 to complete the production of the flexible circuit board 1, as Figure 2a As shown, wherein, in this embodiment, the flexible circuit substrate 11 includes a PI layer 53, an Ad adhesive layer 52 arranged on both sides of the PI layer 53, a copper foil layer 51 arranged on the Ad adhesive layer 52, and the cover film 12 includes Ad glue layer 52 and PI layer 53;

[0060] 2) Prepare the protective film 2. A protective film with a thickness of 12 μm or 25 μm can be selected. In this embodiment, the protective film 2 with a thickness of 25 μm is preferred. The protective film 2 is cut into small pieces according to the shape of the exposed area of the flexible board 1, and the protective film 2 attached to the exposed area, such as Figure 2b shown;

[0061] 3) According to ...

Embodiment 2

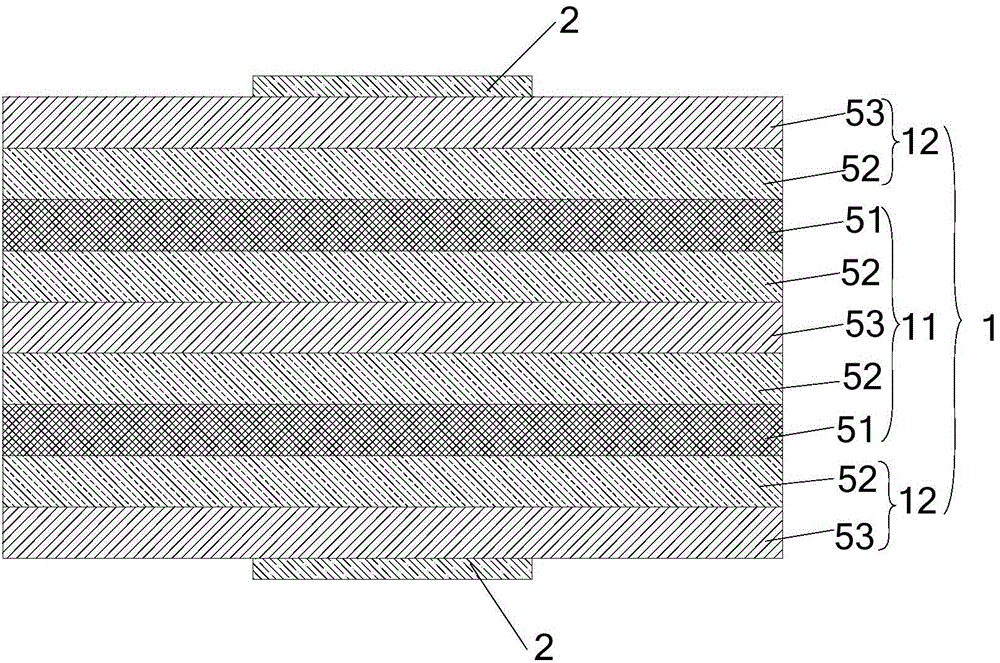

[0067] 1) if Figure 3a As shown, the circuit pattern is made on the flexible circuit substrate 11, and the cover film 12 is attached to complete the production of the flexible circuit board 1;

[0068] 2) Prepare the protective film 2. The protective film 2 with a thickness of 12 μm or 25 μm can be selected. In this embodiment, the protective film 2 with a thickness of 25 μm is preferred. Cut the protective film 2 into small pieces according to the shape of the exposed area of the flexible board 1, and Attach the protective film 2 on the exposed area, such as Figure 3b shown;

[0069] 3) Prepare a copper clad laminate 4 of a certain thickness (the copper clad laminate 4 includes a copper foil layer 51 and a substrate 41), and make alignment target holes and targets on one side;

[0070] 4) According to the stacking requirements, stack the soft board 1 with the protective film 2, the prepreg 3, and the copper clad laminate 4 with the alignment target in order, and press t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com