Method for peeling rigid board from flexible board area of flexible-rigid board

A technology of rigid and flexible boards, applied in the field of soft and hard board technology, can solve the problems of complicated implementation steps, complicated costs, and high costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

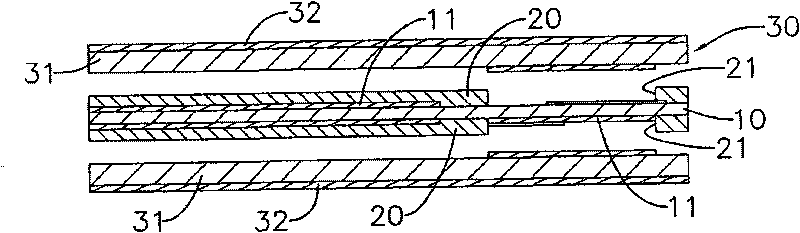

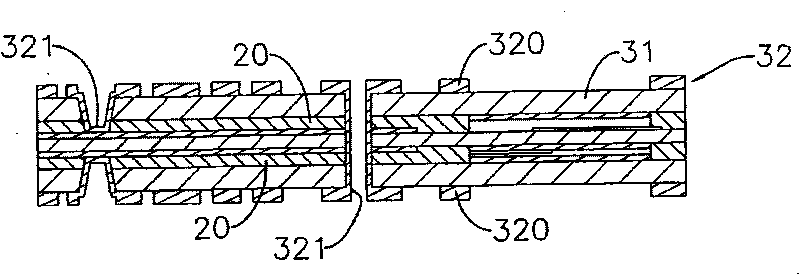

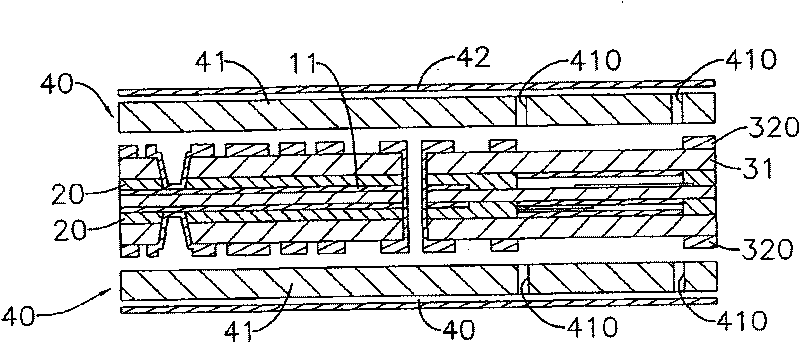

[0032] The specific content about a preferred embodiment of the present invention is described in detail as follows: at first carry out an inner laminate operation, please refer to figure 1 As shown, a flexible board 10 is mainly provided first, and at least one side of the flexible board 10 has a circuit 11. The operation of the inner laminate is to laminate a dielectric material 20 and an inner layer on at least one side of the flexible board 10. The rigid board 30 , in this embodiment, the flexible board 10 has circuits 11 on both sides, and a dielectric material 20 and an inner hard board 30 are provided on the front and back sides for lamination.

[0033] In addition, an opening 21 is respectively formed on the above-mentioned dielectric material 20, and the opening 21 corresponds to the same position on the flexible board 10, and the position of the flexible board 10 is exposed to the opening 21 to form a soft board area, and the soft board area is The part where the fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com