High temperature biobased lubricant compositions from boron nitride

a biobased lubricant and composition technology, applied in the field of biobased lubricant compositions, can solve the problems of insufficient desirable biobased oils, inability to meet the requirements of high temperature, environmental and food-grade lubricants, and many biobased oils that do not possess the desired spectrum of characteristics, etc., to achieve enhanced lubricity, high dielectric strength, and enhanced lubricity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

(A) The Triglyceride Oil

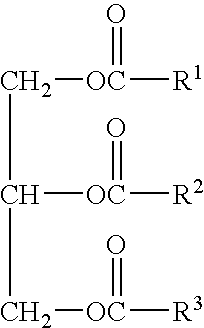

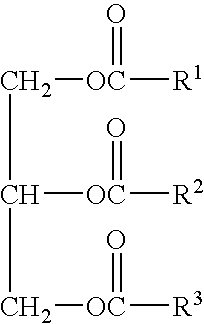

[0048]In practicing this invention, the base oil is a synthetic triglyceride or a natural oil of the formula

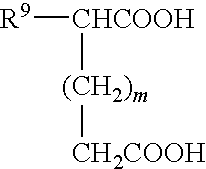

wherein R1, R2 and R3 are aliphatic hydrocarbyl groups that contain from about 7 to about 23 carbon atoms. The term “hydrocarbyl group” as used herein denotes a radical having a carbon atom directly attached to the remainder of the molecule. The aliphatic hydrocarbyl groups include the following: (1) Aliphatic hydrocarbon groups; that is, alkyl groups such as heptyl, nonyl, undecyl, tridecyl, heptadecyl; alkenyl groups containing a single double bond such as heptenyl, nonenyl, undecenyl, tridecenyl, heptadecenyl, heneicosenyl; alkenyl groups containing 2 or 3 double bonds such as 8,11-heptadecadienyl and 8,11,14-heptadecatrienyl. All isomers of these are included, but straight chain groups are used in this embodiment. (2) Substituted aliphatic hydrocarbon groups; that is groups containing non-hydrocarbon substituents which, in the context of this invent...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperatures | aaaaa | aaaaa |

| temperatures | aaaaa | aaaaa |

| viscosity index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com