A water-borne epoxy resin-emulsified bitumen micro-surfacing mixture and a preparing method thereof

A technology of water-based epoxy resin and micro-surfacing mixture, which is applied in the field of road engineering, can solve the problems of caking, destruction of cationic emulsified asphalt balance system, emulsification effect failure, etc., and achieve excellent emulsification performance, compatibility and stability Good, the effect of improving road driving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

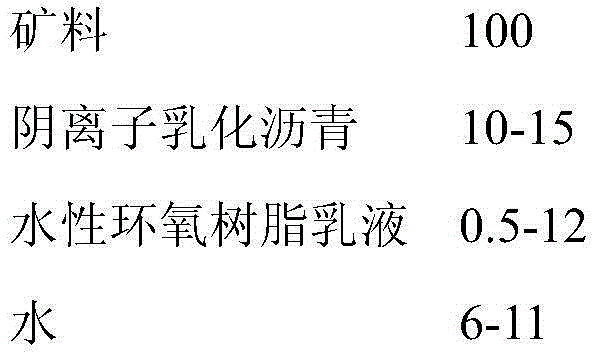

Method used

Image

Examples

Embodiment 1

[0044] 1. Preparation of Waterborne Epoxy Resin Emulsion

[0045] Mix 100g of water-based epoxy resin and 150g of diethylenetriamine, and use a low-speed stirrer to fully stir the mixed emulsion for 7.5 minutes to make the mixture uniform.

[0046] Wherein, waterborne epoxy resin is standard liquid epoxy resin, and its solid content is 75%;

[0047] Wherein, the solid content of diethylenetriamine is 50%.

[0048] 2. Preparation of water-based epoxy emulsified asphalt

[0049] Pour 50g of water-based epoxy resin emulsion into 120g of anionic emulsified asphalt and stir evenly to obtain water-based epoxy emulsified asphalt.

[0050]3. Preparation of Microsurfacing Mix

[0051] Prepare materials according to the following weight ratio:

[0052] Mineral material 1000g

[0053] 80g of water

[0054] Water-based epoxy emulsified asphalt 170g

[0055] Add water to the mineral material, stir evenly at room temperature, then add water-based epoxy resin emulsified asphalt, and c...

Embodiment 2

[0058] 1. Preparation of Waterborne Epoxy Resin Emulsion

[0059] Mix 10g of water-based epoxy resin and 20g of polyamide-650, and use a low-speed stirrer to fully stir the mixed emulsion for 5 minutes to make the mixture uniform.

[0060] Wherein, water-based epoxy resin is water-soluble epoxy resin, and its solid content is 50%;

[0061] Among them, the solid content of polyamide-650 is 70%.

[0062] 3. Preparation of water-based epoxy emulsified asphalt

[0063] Pour 10g of water-based epoxy resin emulsion into 120g of anionic emulsified asphalt and stir evenly to obtain water-based epoxy emulsified asphalt.

[0064] 4. Preparation of Microsurfacing Mix

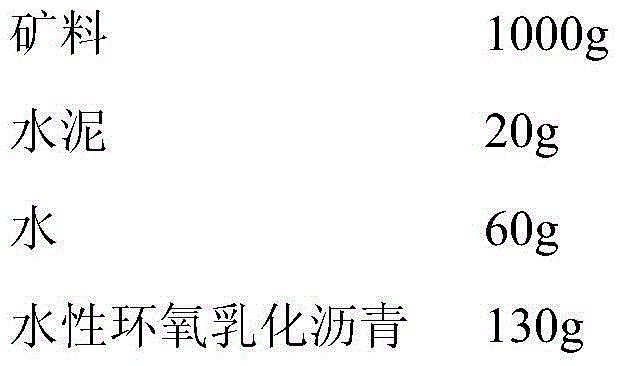

[0065] Prepare materials according to the following weight ratio:

[0066]

[0067] Add cement to the mineral material, stir evenly at room temperature, then add water, continue to stir to form a uniform mixture, then add water-based epoxy resin emulsified asphalt, continue to stir for 30 seconds, and the product is...

Embodiment 3

[0070] 1. Preparation of Waterborne Epoxy Resin Emulsion

[0071] Mix 10g of water-based epoxy resin and 10g of N,N'-dihydroxyethyldiethylenetriamine, then add 30g of water and use a low-speed stirrer to fully stir the mixed emulsion for 10 minutes to make the mixture uniform.

[0072] Wherein, the water-based epoxy resin is a water-soluble epoxy resin, and its solid content is 100%;

[0073] Among them, the solid content of N,N'-dihydroxyethyldiethylenetriamine is 30%.

[0074] 4. Preparation of water-based epoxy emulsified asphalt

[0075] Pour 10g of water-based epoxy resin emulsion into 100g of anionic emulsified asphalt and stir evenly to obtain water-based epoxy emulsified asphalt.

[0076] 5. Preparation of Microsurfacing Mix

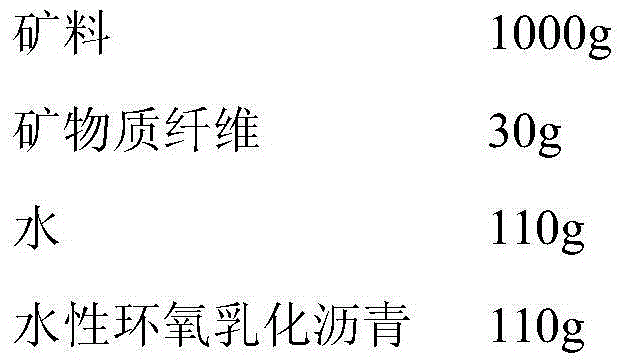

[0077] Prepare materials according to the following weight ratio:

[0078]

[0079] Add the mineral fiber to the mineral material, stir evenly at room temperature, then add water, continue to stir to form a uniform mixture, then add water-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com