Asphalt mixture for rapid repair of hot-mix-cold-laid pavement

A technology of asphalt mixture and cold paving, which is applied to the coagulation pavement, roads, roads and other directions of on-site paving, which can solve the problem of unknown formula and other problems.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0057] Increase petroleum resin in the liquid asphalt of embodiment 1 and improve asphalt performance

[0058] In PG-70SBS modified bitumen (purchased from Zhenjiang Koshi Asphalt Products Co., Ltd.), the petroleum resin (purchased from Landun Chemical Co., Ltd. Co., Ltd.), test the penetration, softening point and ductility of asphalt before and after mixing (perform according to the current "Test Regulations for Asphalt and Asphalt Mixtures in Highway Engineering" (JTJ052-2000)), and test the performance of asphalt.

[0059]

[0060] It can be seen from the table that after adding 2% petroleum resin, the performance of asphalt has been significantly improved.

Embodiment 2-6

[0061] Example 2-6 Liquid asphalt adhesion test

[0062] Based on the weight of modified asphalt, adopt the following weight percentage content formula to configure liquid asphalt (percentages are all weight percentages based on the weight of modified asphalt):

[0063]

[0064] Anti-stripping agent: TJ066 asphalt anti-stripping agent produced by Shanghai Tonglu Material Technology Co., Ltd.

[0065] Select aggregates and mineral powders that meet the technical requirements of the "Code for Design of Asphalt Concrete Pavements at Civil Airports" (MH 5010-1999).

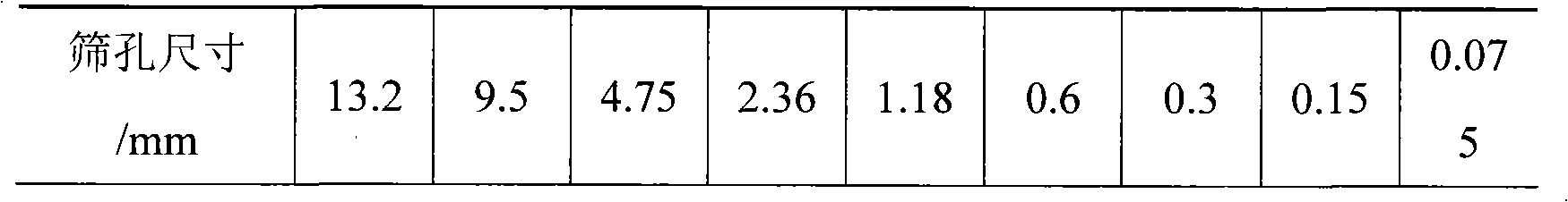

[0066] The coarse aggregate is basalt, the fine aggregate is limestone, and the aggregate gradation is as follows:

[0067]

[0068] When preparing, first mix the appropriate amount of coarse and fine aggregates evenly and heat to 110-120°C; then heat PG-70SBS modified asphalt to 150°C, then add the weighed diluent, anti-stripping agent, petroleum resin, and stir for 15 Make liquid asphalt after ~20min, accura...

Embodiment 7

[0070] The selection experiment of embodiment 7 mineral powder consumption

[0071] The liquid asphalt formula of embodiment 6 is selected, and aggregates and mineral powders meeting the technical requirements of "Code for Design of Asphalt Concrete Pavements of Civil Airports" (MH5010-1999) are selected.

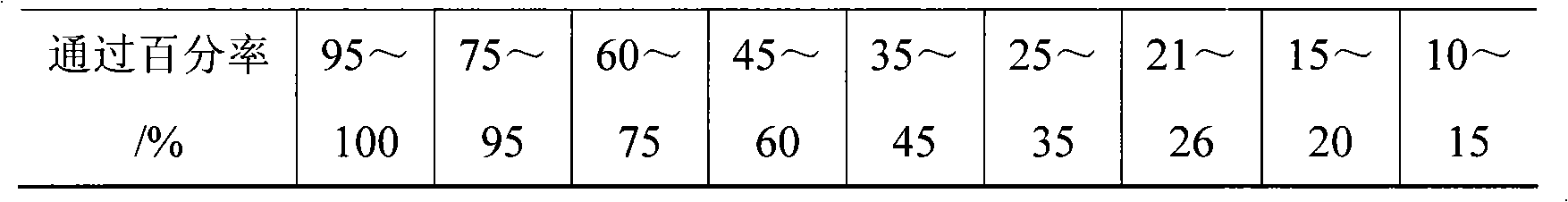

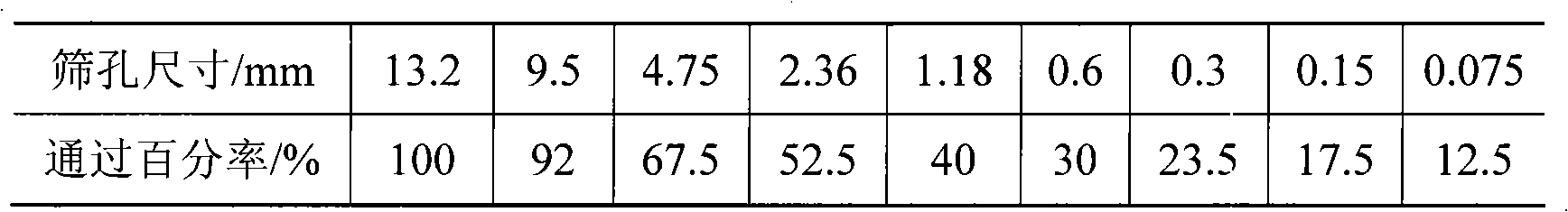

[0072] The coarse aggregate is basalt, the fine aggregate is limestone, and the gradation is as follows:

[0073]

[0074] Adopt the method for embodiment 6 to make liquid asphalt, then carry out the mixing of mixture:

[0075] (1) Add an appropriate amount of coarse aggregate and fine aggregate into a mixing tank at 110-120°C and heat and stir evenly.

[0076] (2) Weigh 6%, 10%, and 15% mineral powder of aggregate total amount respectively.

[0077] (3) According to the different amount of mineral powder, the correspondingly weighed liquid asphalt (admixture added) with an asphalt ratio of 5.0% is heated to 90-100°C, and then added to the mixing tank and aggregated us...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| stability | aaaaa | aaaaa |

| stability | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com