Warm-mix asphalt additive and preparation method thereof

A technology of warm-mix asphalt and additives, applied in building insulation materials, building components, climate change adaptation, etc., can solve the problems of poor reduction performance of asphalt binder, water damage resistance, poor adhesion performance, etc., to improve the initial strength and water damage resistance, improved rutting resistance, and convenient construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

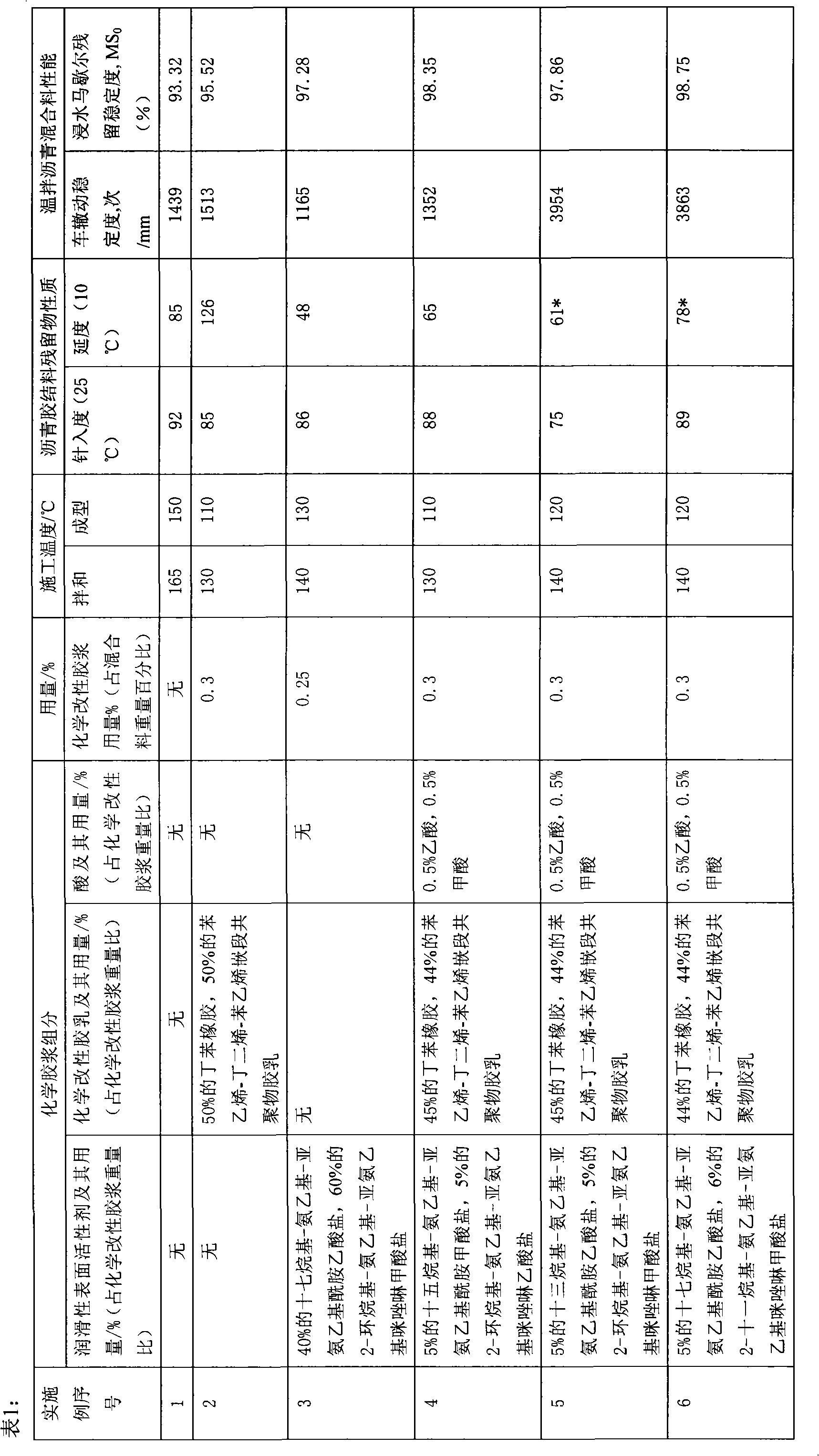

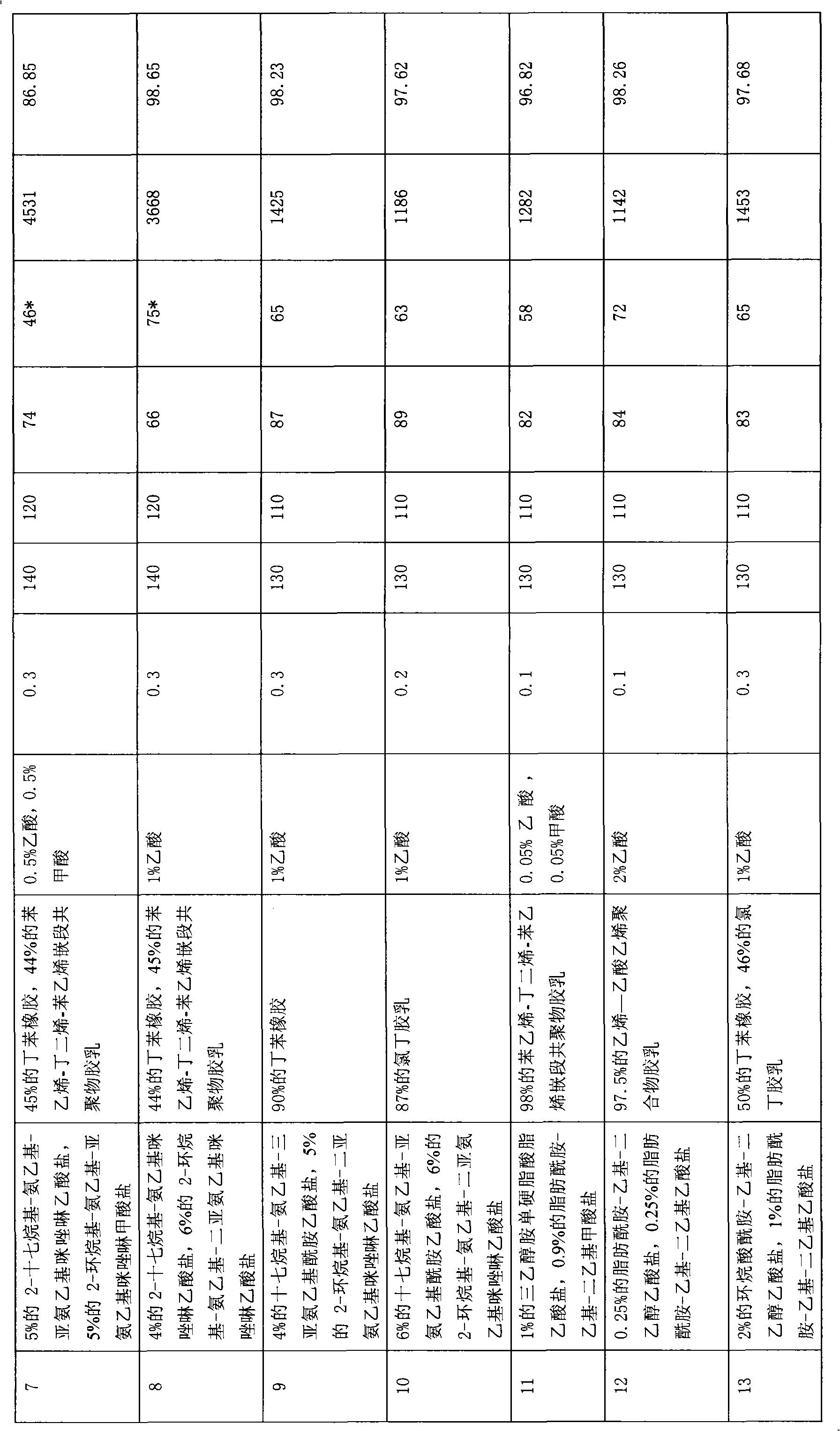

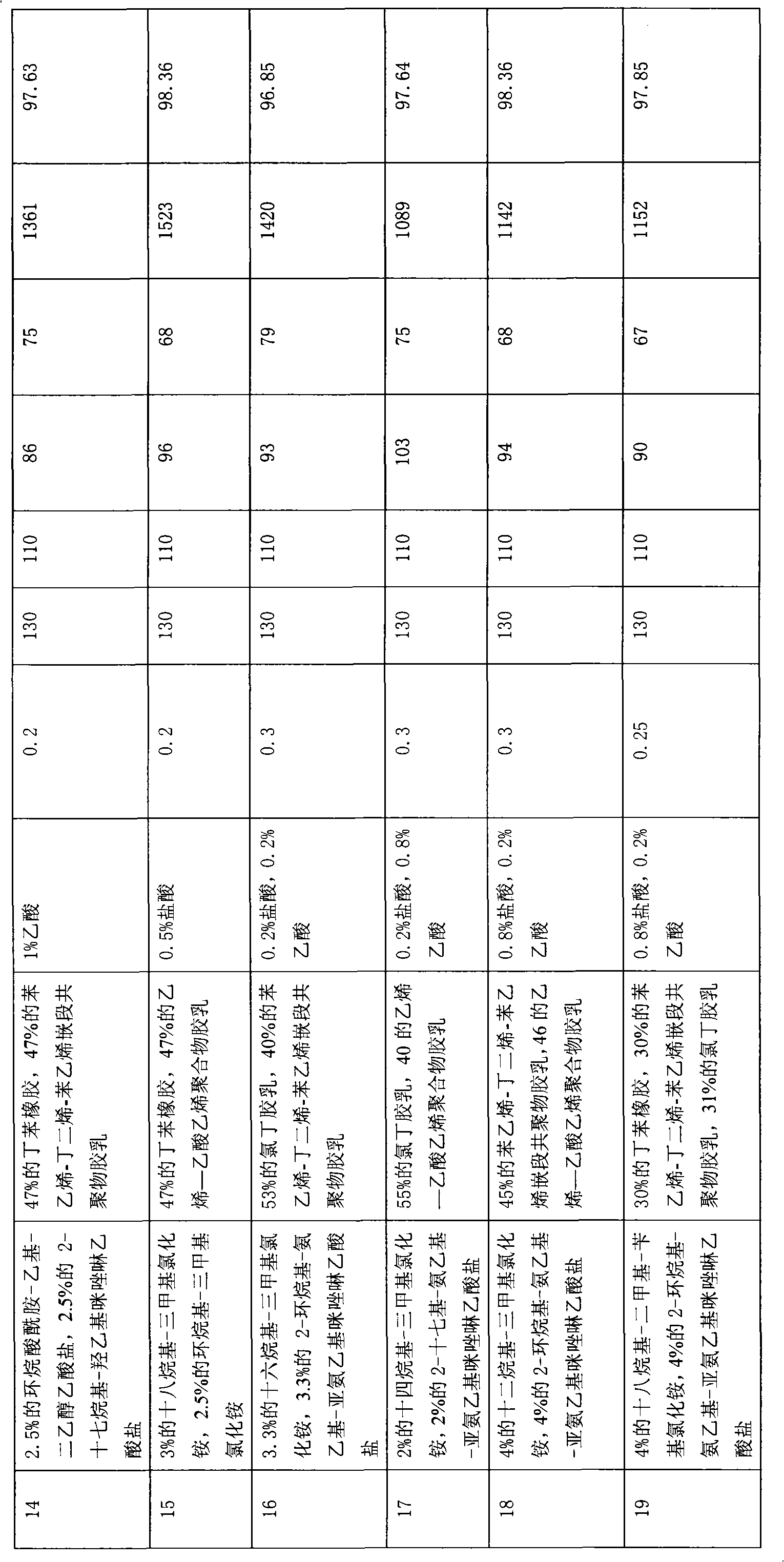

[0038] is the performance of base asphalt and its hot-mix asphalt mixture, and Example 2 and Example 3 are respectively the asphalt reduction performance and warm-mix asphalt mixture using chemically modified mortar, using lubricity and anti-stripping cationic surfactants Performance, Example 4 is the performance of matrix asphalt reduction performance and its mixture tested by using the warm mix asphalt additive provided by the present invention. Examples 1 to 4 show that: use chemically modified mortar and lubricity and anti-stripping cations Surfactants can improve the elongation performance, spalling resistance and water damage resistance of base asphalt respectively. Examples 5-8 are the test results of warm-mix asphalt reduction performance and its mixture performance using different modified asphalt binders. The asphalt is roughly equivalent; Examples 9-22 are warm mix asphalt additives prepared with different chemically modified latexes, and the implementation effect s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com