Modified asphalt material for airport pavement, preparation method and applications thereof

A technology of modified asphalt and asphalt mixture, which is applied to building insulation materials, building components, buildings, etc., to improve low temperature performance and fatigue resistance, reduce permanent deformation, and solve wheel rutting and early disease problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

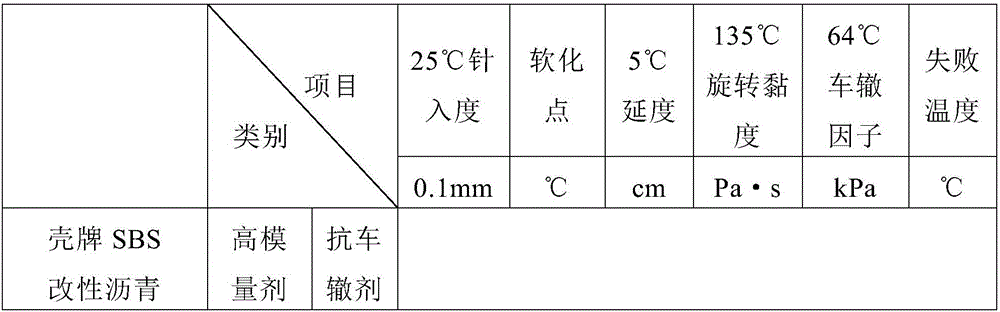

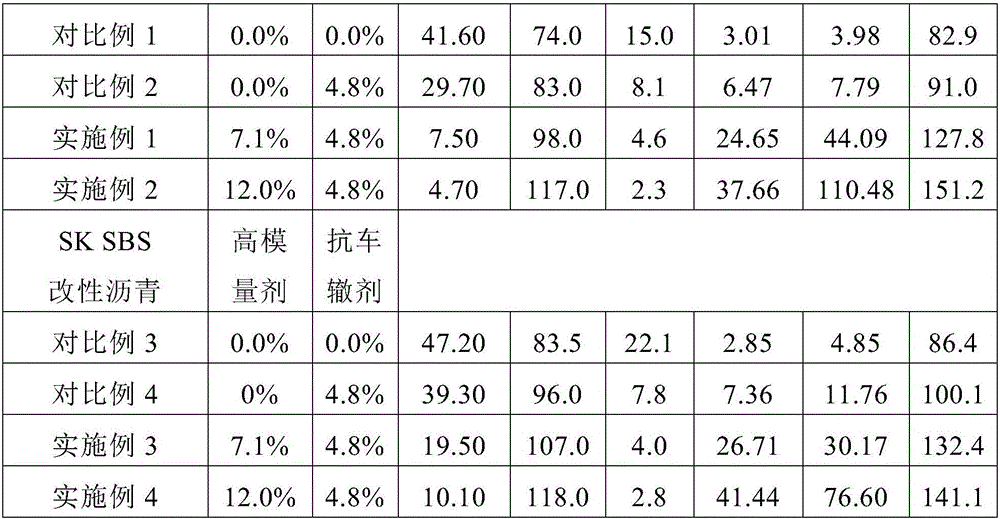

Embodiment 1

[0038] The modified asphalt material in this example is prepared by adding high modulus agent and anti-rutting agent to SBS modified asphalt. Shell SBS modified asphalt is used, the base asphalt grade is PG 64-22, and the content of SBS relative to base asphalt is 3 %, the high modulus agent adopts high-density polyethylene, and the anti-rutting agent adopts polypropylene, rubber powder and SBS thermoplastic elastomer mixture.

[0039]The preparation method is as follows: heat SBS modified asphalt to 180°C, stir with a shearing machine at a rate of 8000 rpm for 40 minutes at a constant temperature; keep the temperature at 180°C, slowly add anti-rutting agent and high modulus agent in batches, and use a shearing machine to Stir at a rate of 20,000rpm for 40 minutes to disperse evenly; at a constant temperature of 140°C, shear and develop at a rate of 8,000rpm for 40 minutes to obtain the modified asphalt material.

Embodiment 2

[0041] This example is roughly the same as Example 1, using Shell SBS modified asphalt, the base asphalt grade is No. 70 asphalt, and the anti-rutting agent is a mixture of high-density polyethylene, rubber powder and thermoplastic elastomer SBS. Heat the asphalt to 185°C, stir with a shearer at a rate of 12,000rpm for 60min at a constant temperature; keep the temperature at 185°C, slowly add anti-rutting agent and high modulus agent in batches, stir with a shearer at a rate of 30,000rpm for 60min, and disperse Uniform; at a constant temperature of 160°C, and then sheared at a rate of 10,000rpm for 60min, the modified asphalt material is obtained.

Embodiment 3

[0043] This example is roughly the same as Example 1, using SK SBS modified asphalt, the grade of base asphalt is PG 64-16, the high modulus agent is polypropylene, and the anti-rutting agent is polyethylene, rubber powder and thermoplastic elastomer SIS mixture. The preparation method is as follows: heat SBS modified asphalt to 182°C, stir with a shearing machine at a rate of 10,000 rpm for 50 minutes at a constant temperature; keep the temperature at 182°C, slowly add anti-rutting agent and high modulus agent in batches, and use a shearing machine Stir at a rate of 25,000 rpm for 50 minutes to disperse evenly; at a constant temperature of 150°C, shear and develop at a rate of 9,000 rpm for 50 minutes to obtain the modified asphalt material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com