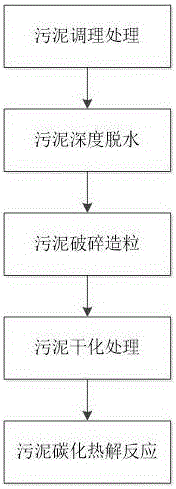

Sludge treatment and recycling method

A sludge treatment and recycling technology, applied in sludge treatment, water/sludge/sewage treatment, water/sewage treatment, etc., can solve the problems of limited resource utilization, high operating costs, and limited popularization and application , to achieve the effects of harmless and resourceful treatment and disposal, high economic and social value, and high economic added value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

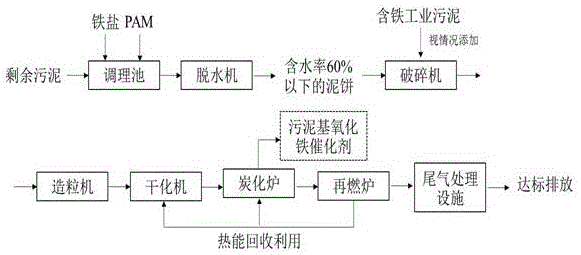

Method used

Image

Examples

Embodiment example 1

[0038] The remaining sludge of a municipal sewage plant has a water content of 99% and an organic content of 70%. Ferrous sulfate is added at 300kg / t DS on a dry basis, coagulated in a conditioning tank for 8 minutes, and then at 1.5kg / t DS. Add cationic PAM in liquid state, stir slowly for 3 minutes and pump it into a plate and frame filter press for deep dehydration to obtain a mud cake with a moisture content of 55%. After being crushed and granulated, it enters the paddle dryer, uses the heat released by the combustion of the pyrolysis gas produced by the carbonization furnace to heat the heat transfer oil, and then uses the heat transfer oil to heat the hollow paddle dryer to dry the sludge to moisture content 22%, the dried sludge enters the rake-tooth multi-stage furnace for pyrolysis and carbonization for 45 minutes, the final temperature is 550 degrees Celsius, and the sludge-based iron oxide catalyst is obtained.

[0039] After testing, there are 2-50nm mesopores on the...

Embodiment example 2

[0042] The remaining sludge of a municipal sewage plant has a water content of 99% and an organic content of 70%. Polyaluminum ferric sulfate is added at 200kg / t DS on a dry basis, coagulated in a conditioning tank for 8 minutes, and then at 1.2kg / t DS Add PAM in liquid form, stir slowly for 3 minutes, then pump into the plate and frame filter press for deep dehydration to obtain a mud cake with a moisture content of 55%. After being crushed and dried by a hollow paddle dryer, the sludge with a water content of 20% is sent to a carbonization furnace for pyrolysis for 55 minutes, with a final temperature of 600 degrees Celsius, to obtain a sludge-based iron oxide catalyst, which is carried out using the catalyst prepared by the above method Ozone catalytic oxidation treatment of biochemical tail water in the Fine Chemical Park.

[0043] The tail water pH is about 7, BOD5 / COD is about 0.08, and COD is about 140 mg / L. An ozone oxidation reaction column made of tempered glass, with ...

Embodiment example 3

[0046] The remaining sludge of a municipal sewage plant has a water content of 97% and an organic content of 60%. Polyferric sulfate is added at 200kg / t DS on a dry basis, coagulated in a conditioning tank for 6 minutes, and then at 1.3kg / t DS. Add PAM in the liquid state, stir slowly for 3 minutes, and then pump into the plate and frame filter press for deep dehydration to obtain a mud cake with a moisture content of 56%. In the crushing process, continue to add solid ferrous sulfate, after mixing and drying by the sludge dehumidification dryer, the sludge with a water content of 20% is sent to the carbonization furnace for pyrolysis for 65 minutes, and the final temperature is 650 degrees Celsius to obtain sludge. Based iron oxide magnetic adsorbent.

[0047] In the emergency super-magnetic separation water purification station with a processing capacity of 20000m3 / d, the magnetic adsorbent prepared by this method is used to replace the magnetic powder to treat river water. Whe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com