Method for preparing high-temperature resistant anti-infrared thermal radiation energy-saving coating

An energy-saving coating and heat radiation technology, applied in the field of heat-insulating coatings, can solve problems such as high reflectivity, achieve high reflectivity, simple construction, and improved infrared reflection performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

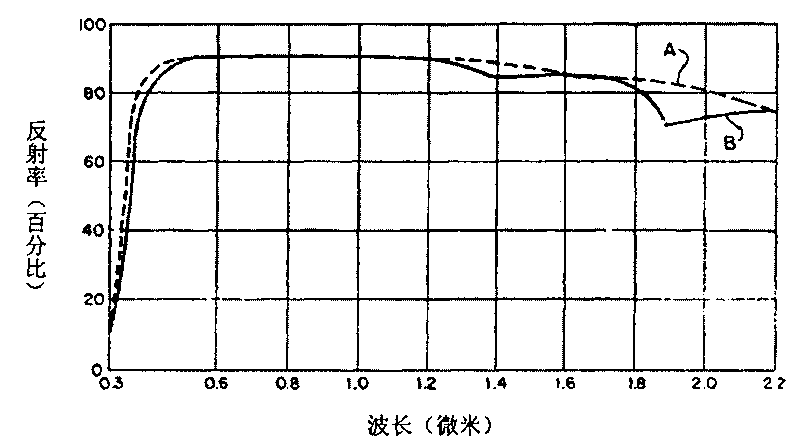

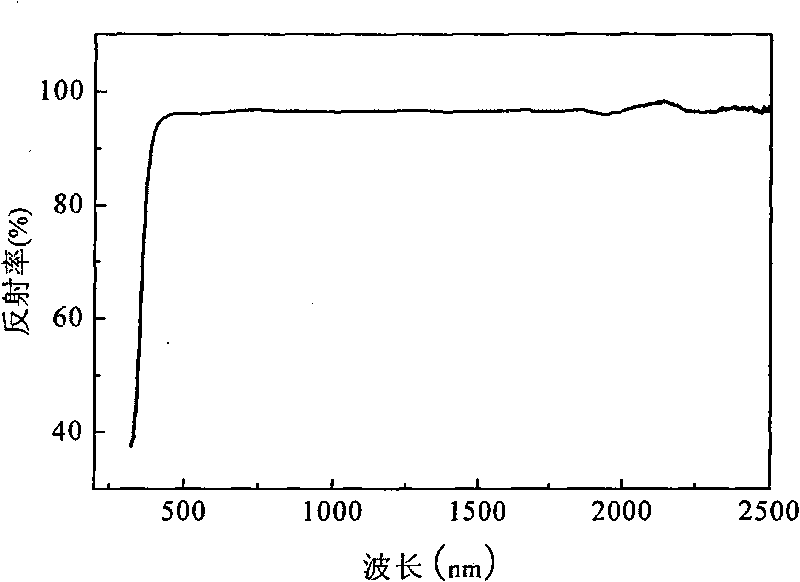

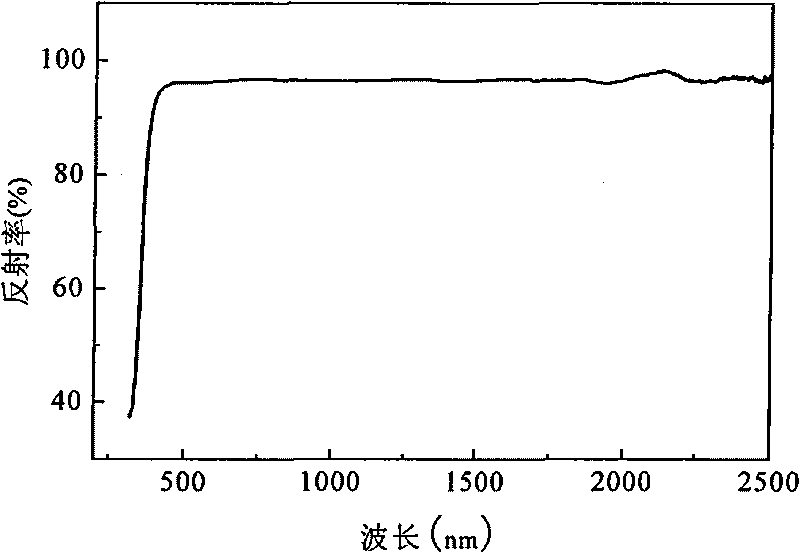

[0025] Potassium hexatitanate whiskers with a whisker length of 10-50 μm are added to the sol containing titanium and potassium elements, and the content of titanium and potassium elements is measured as TiO 2 、K 2 O meter, TiO 2 : K 2 O=6:1 (molar ratio), stir evenly to form a slurry, the content of whiskers in the slurry is 40wt%; the slurry is coated on the surface of traditional refractory materials, and sintered at 500 ° C for 0.5h to form a thickness of 2mm coating. The reflectance of the coating at a wavelength of 300-2500nm was tested with a lambda 950 UV-visible spectrophotometer, and the results are shown in the attached figure 2 As shown, the reflectivity of the coating to the wavelength of 500-2500nm is greater than 96%, and there is no attenuation in the entire wavelength range, while the attached figure 1 The infrared reflectance (curve B) of the heat insulation material invented by the patent USA: US3296060 and the infrared reflectance (curve A) of the heat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com