Folding-resistant one-dimensional fibrous flexible energy storage device and preparation method thereof

A fibrous, folded technology, used in the manufacture of hybrid/electric double-layer capacitors, electrical components, structural parts, etc., can solve the problem that the separator and the electrode material cannot be tightly adsorbed together, the specific capacity of the energy storage device is reduced, and the structure is compact. Type difference and other problems, to achieve the effect of improving folding resistance and electrochemical stability, improving folding resistance and electrochemical stability, reducing size and assembly cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

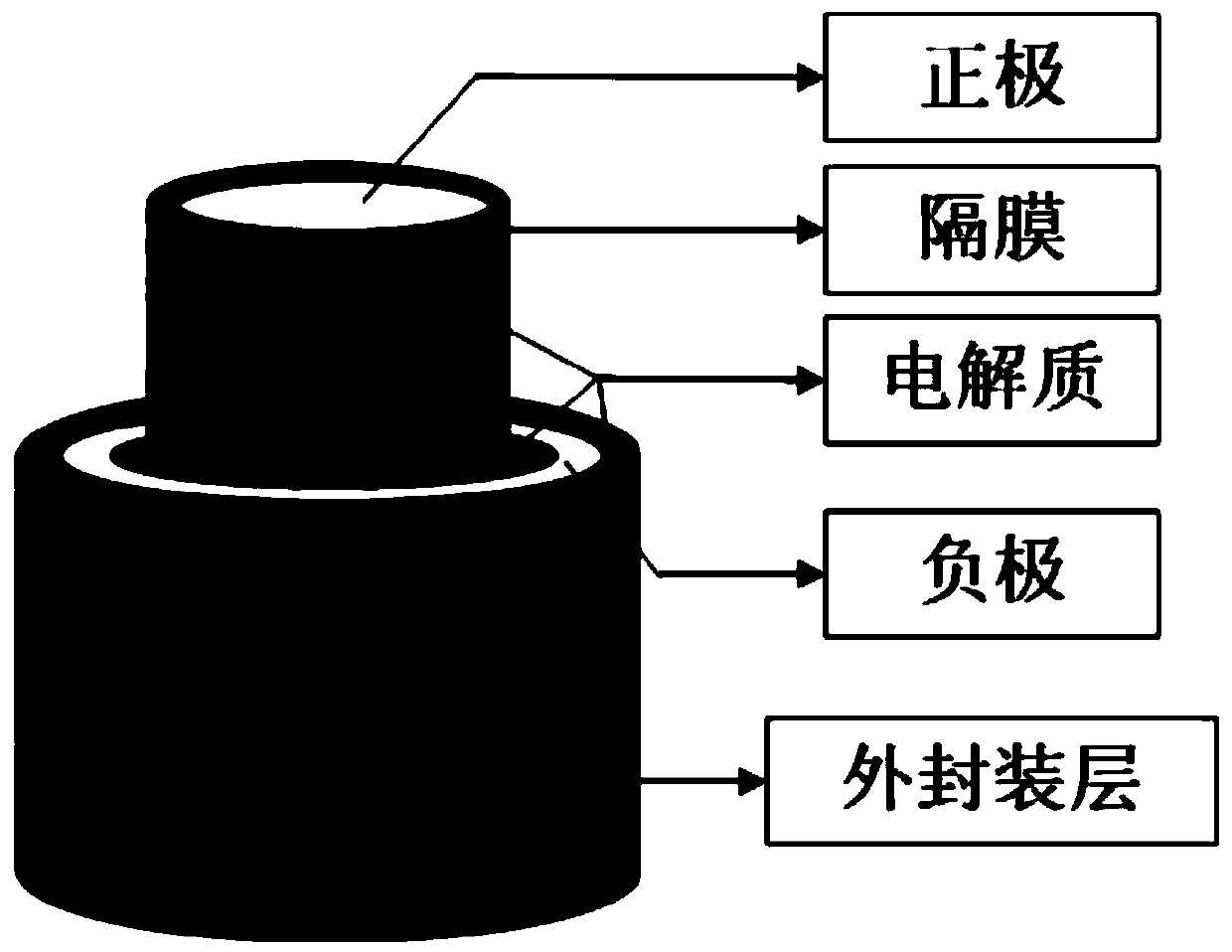

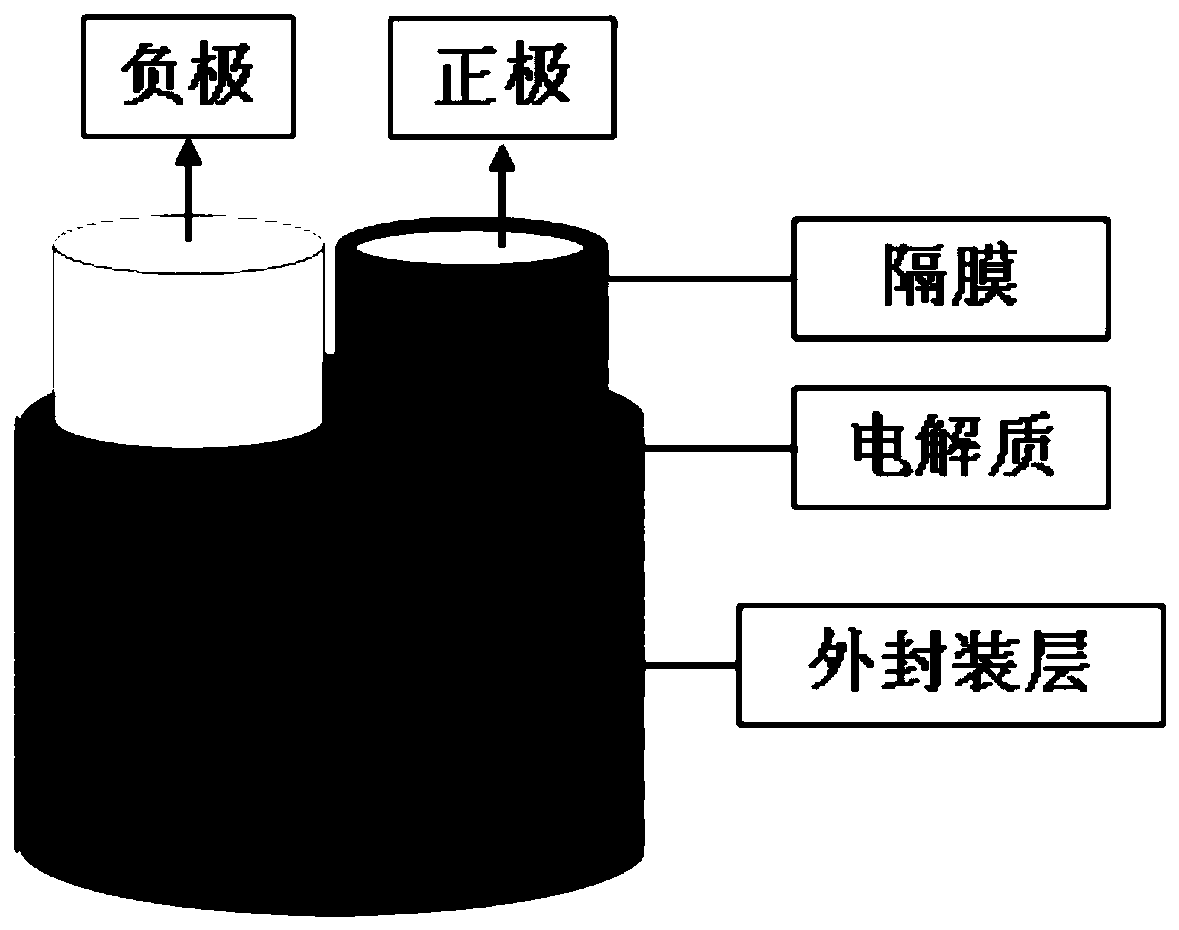

[0074] Specifically, a method for preparing a folding-resistant one-dimensional fibrous flexible energy storage device includes the following steps:

[0075] 1) Precipitation method, hydrothermal method, vacuum filtration method, chemical vapor deposition method, electroplating method or ice bath method are used to prepare positive and negative electrodes; the material forming the positive electrode is a flexible fiber material with high conductivity and electrochemical activity at the same time For example, the material forming the positive electrode can be a combination of non-conductive flexible fibers and conductive agents and / or conductive flexible fibers or flexible conductive fibers and electrochemically active substances (wherein, the source of the non-conductive flexible fibers includes cotton fabrics, wool fabrics, Any one or a combination of two or more of silk fabrics, hemp fabrics, polyester fabrics, and acrylic fabrics; the conductive agent includes any one or two...

Embodiment 1

[0084] A method for preparing a folding-resistant fibrous supercapacitor, comprising:

[0085] 1) Using carbon nanotube film as conductive substrate, carbon nanotube / MnO was prepared by electroplating method 2 The composite film is then twisted into a flexible fiber as the positive electrode; the carbon nanotube film is also used as the substrate, and the carbon nanotube / polyaniline flexible film is prepared by electroplating as the negative electrode;

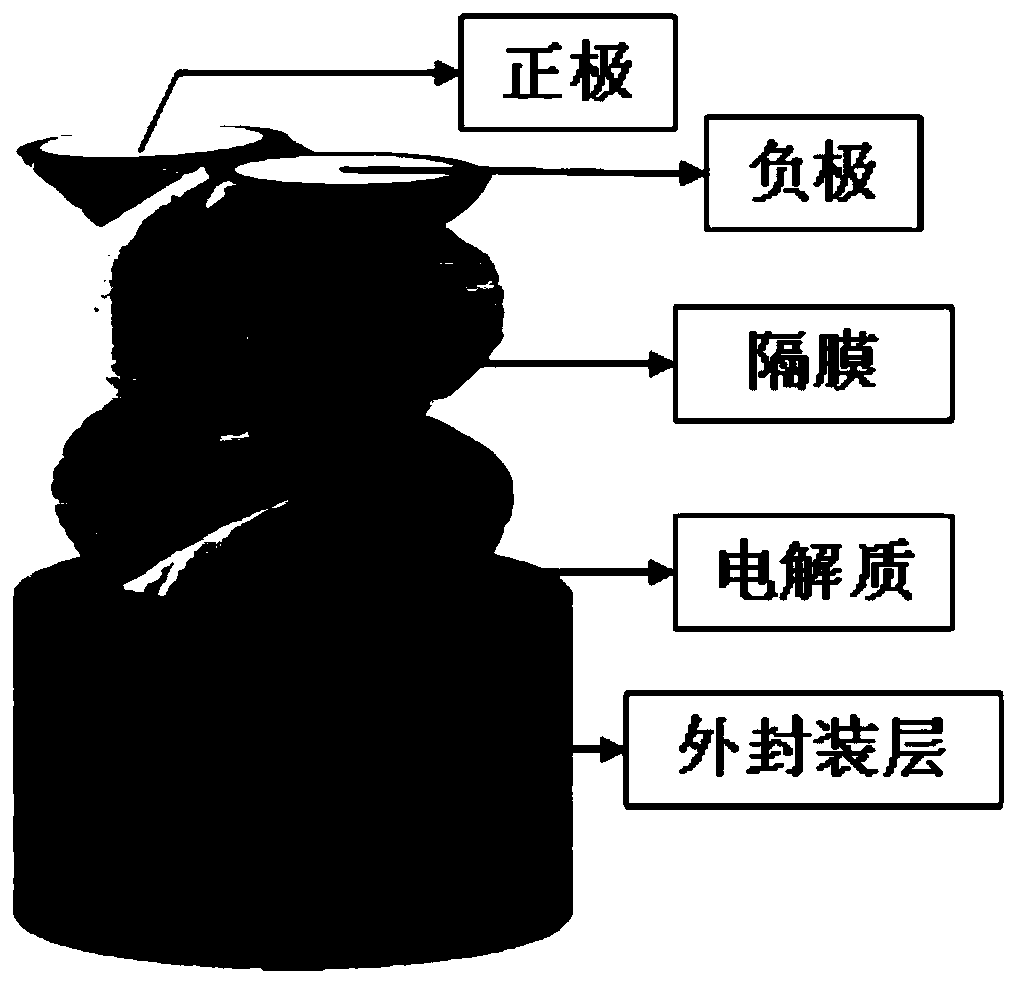

[0086] 2) In-situ electrospinning technology is used to in-situ coat the surface of the positive electrode to form a polyacrylonitrile nanofiber membrane as a separator, and the thickness of the separator is 4-5 μm;

[0087] 3) Preparation of PVA / H 3 PO 4 electrolyte;

[0088] 4) Vacuum-immerse the negative electrode and the positive electrode covered with a separator in the electrolyte at 60°C for 2 hours, and then dry it at 60°C for half an hour to form a solid electrolyte on the surface of the negative electrode and the ...

Embodiment 2

[0095] A method for preparing a folding-resistant fibrous supercapacitor, comprising:

[0096] 1) Using carbon nanotube film as conductive substrate, carbon nanotube / MnO was prepared by electroplating method 2 The composite film is then twisted into a flexible fiber as the positive electrode; the carbon nanotube film is also used as the substrate, and the carbon nanotube / polyaniline flexible film is prepared by electroplating as the negative electrode;

[0097] 2) In-situ electrospinning technology is used to in-situ coat the surface of the positive electrode to form a polyacrylonitrile nanofiber membrane as a separator, and the thickness of the separator is 4-5 μm;

[0098] 3) Preparation of PVA / LiCl electrolyte;

[0099] 4) Vacuum-immerse the negative electrode and the positive electrode covered with a separator in the electrolyte at 60°C for 2 hours, and then dry it at 60°C for half an hour to form a solid electrolyte on the surface of the negative electrode and the positi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com