A paper-plastic composite-transfer process using one-component solvent-free glue

A paper-plastic composite and solvent-free technology, which is applied in the process of producing decorative surface effects, printing technology, printing of special varieties of printed matter, etc., can solve the problem of poor composite firmness and folding resistance, and the inability to apply solvent-free glue , poor wet strength, etc., to achieve superior folding resistance, reduce viscosity, and improve fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0027] 1. Preparation of the glue

[0028] (1) glue recipe:

[0029] Table 1

[0030]

[0031] (2) Preparation:

[0032] A. By the above formulation, polyethylene glycol, polyoxypropylene glycol and polyoxypropylene triol placed in a four-necked flask and heated to 110-120 deg.] C, under vacuum conditions -0.1MPa, dehydration 1-2 hours, detection system passing a water content of less than 0.05%, cooled to 40 ℃, stand;

[0033] B. was added to the four-necked flask diphenylmethane diisocyanate, with an organic tin as a catalyst were added butanediol chain extender, water scavenger triethyl orthoformate, warmed to 85 ~ 95 ℃, 4 hours, 40 ℃ cooling to obtain the desired product.

[0034] (3) detection parameters of the target product prepared as described above is obtained the following results:

[0035] Table 2

[0036]

[0037] 2, plastic composite - technology transfer process parameters are as follows:

[0038] table 3

[0039]

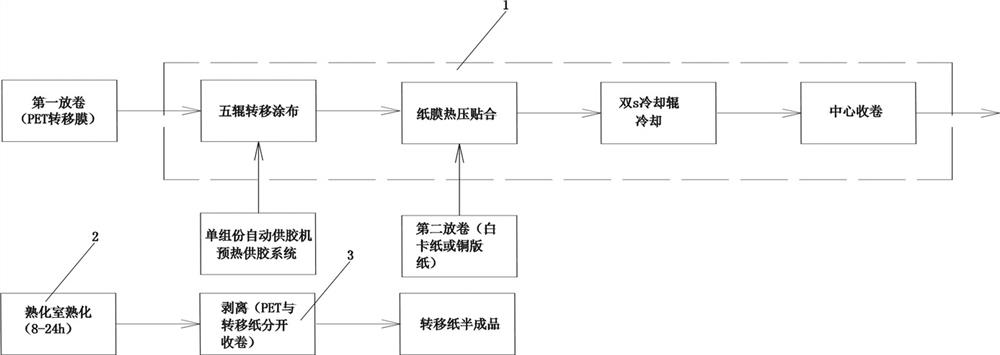

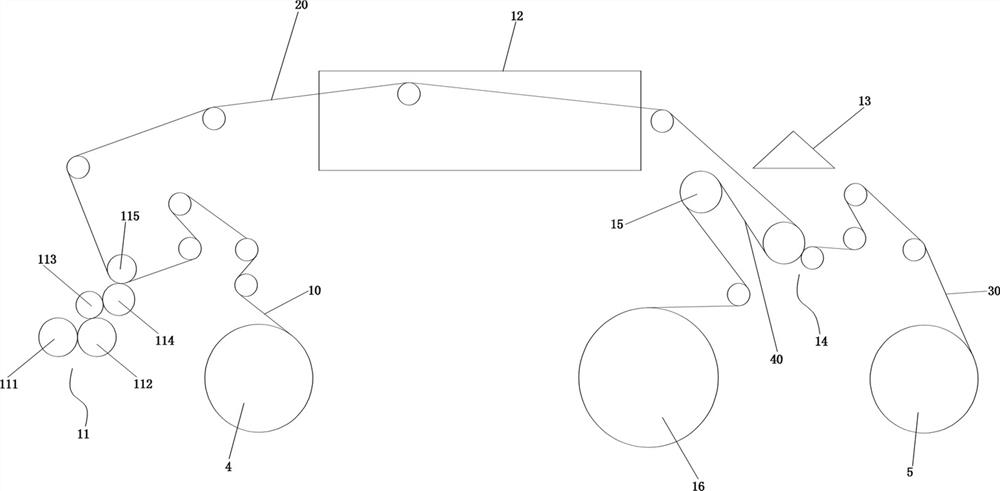

[0040] 3, composite-transfer

[0041] With the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com