Preparation method of renewable low concentration CO2 high efficient absorption material

An adsorption material and low-concentration technology, which is applied in the field of preparation of renewable low-concentration CO2 high-efficiency adsorption materials, can solve the problems of cycle absorption/desorption adsorption capacity decline, difficulty in ensuring material uniformity, and high water content, and achieve adsorption capacity Large, high nitrogen content, large pore volume effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] (1) Mix ethyl orthosilicate, water, ethanol, and hydrochloric acid in a molar ratio of 1:1:5:0.0018, and after standing for 2 hours, add ammonia water in the amount of hydrochloric acid and other substances, and press ethyl orthosilicate and The molar ratio of water is 1:7 to make up water, adjust the temperature to -15°C to obtain silica sol; mix aminopropyltriethoxysilane (the amount of the substance is 0.65 times that of tetraethyl orthosilicate) and ethanol in a molar ratio of 1 : 5 mix evenly, and adjust the temperature to -15°C to obtain an aminosiloxane solution;

[0035] (2) Mix the silica sol and the aminosiloxane solution uniformly to obtain a mixed sol. Adjust the simethicone oil to -15°C, and under the condition of mechanical stirring at a stirring speed of 200r / min, add the mixed sol and simethicone oil into the simethicone oil at a volume ratio of 1:5 to obtain a mixed sol suspension liquid, keep the stirring speed until the mixed sol gels to obtain a sph...

Embodiment 2~24

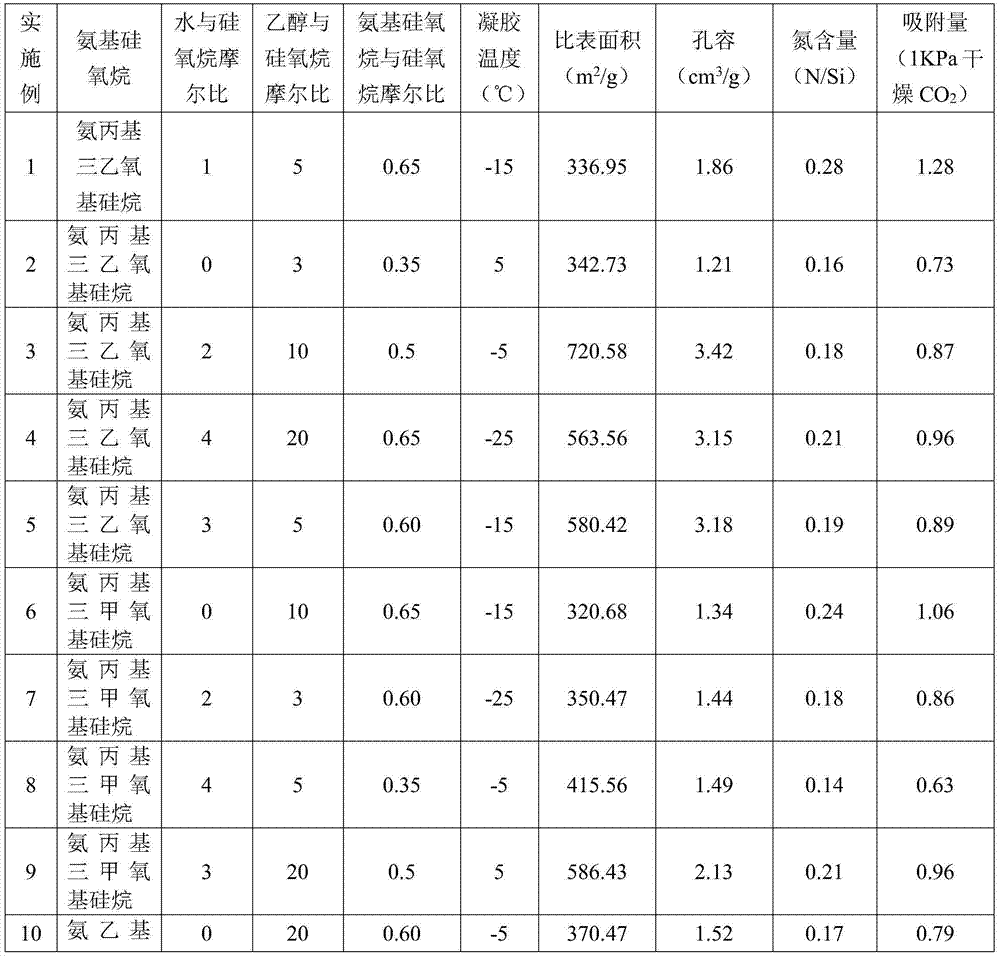

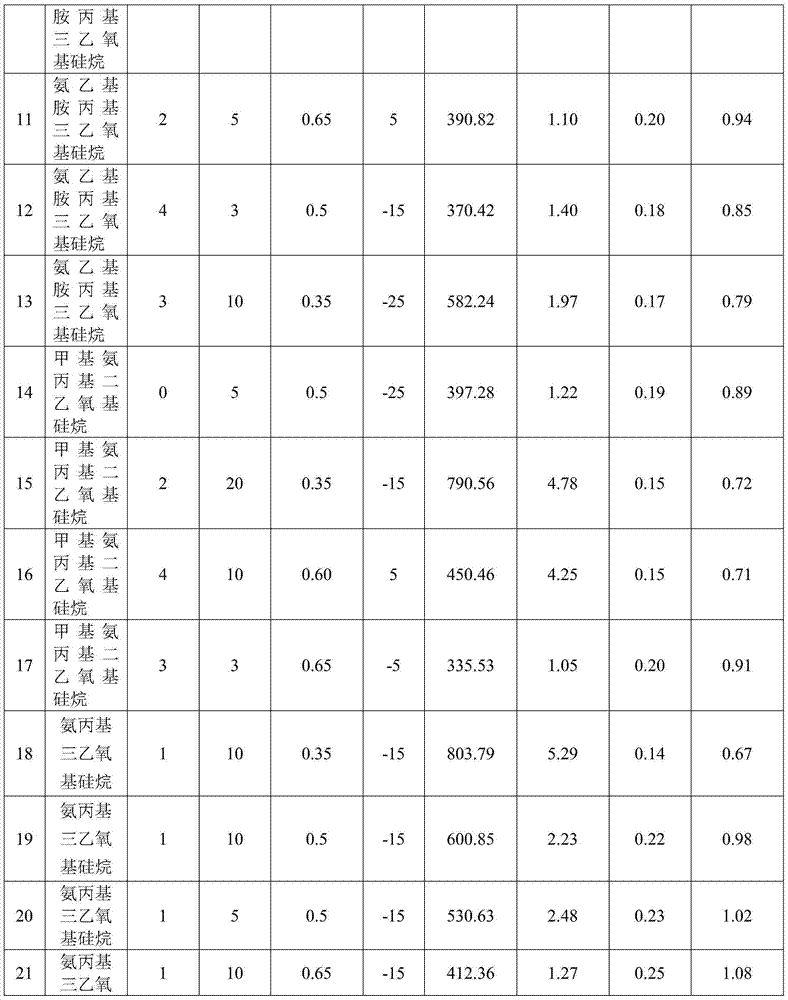

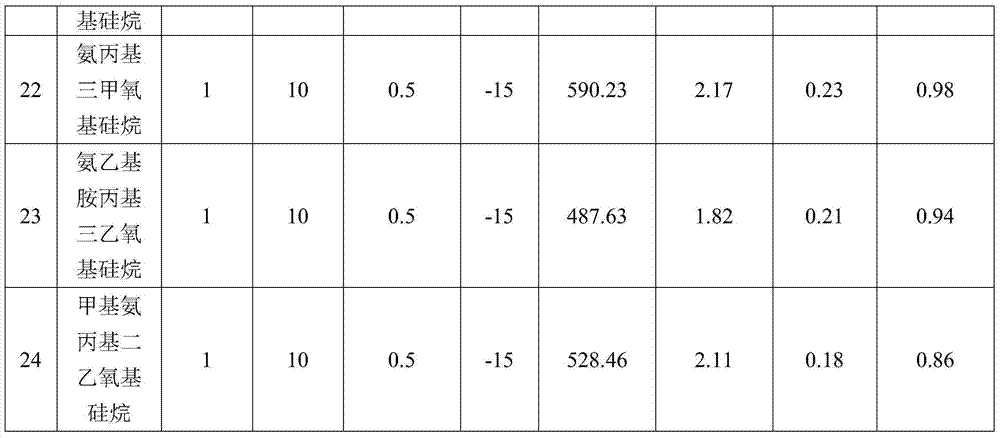

[0046] The process parameters used in Examples 2 to 24 are shown in Table 1, because they affect the renewable low-concentration CO 2 The process parameters of the main performance of high-efficiency adsorption materials are mainly the molar ratio of water to siloxane in silica sol, the molar ratio of ethanol to siloxane, the molar ratio of aminosiloxane to siloxane, the type of aminosiloxane and 5 parameters such as gel temperature, and the type and amount of acid and alkaline catalysts and the type of siloxane mainly affect the gel time, but have little impact on its main performance, so the embodiments 2-24 mainly change these 5 parameters. Process parameters to further explain the present invention. Except the technological parameter written in the table, all the other technological parameters are identical with embodiment 1.

[0047] In Table 1, the process parameters of Examples 2 to 17 are set using the idea and method of orthogonal design (that is, the aminosiloxane i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average diameter | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Pore volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com