Vibration sorting screen

A cleaning screen and cleaning technology, which is applied in the direction of filter screen, solid separation, grille, etc., can solve the problem of uneven distribution of materials in the axial direction, and achieve the effect of strong adaptability, small cleaning loss and high cleanliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

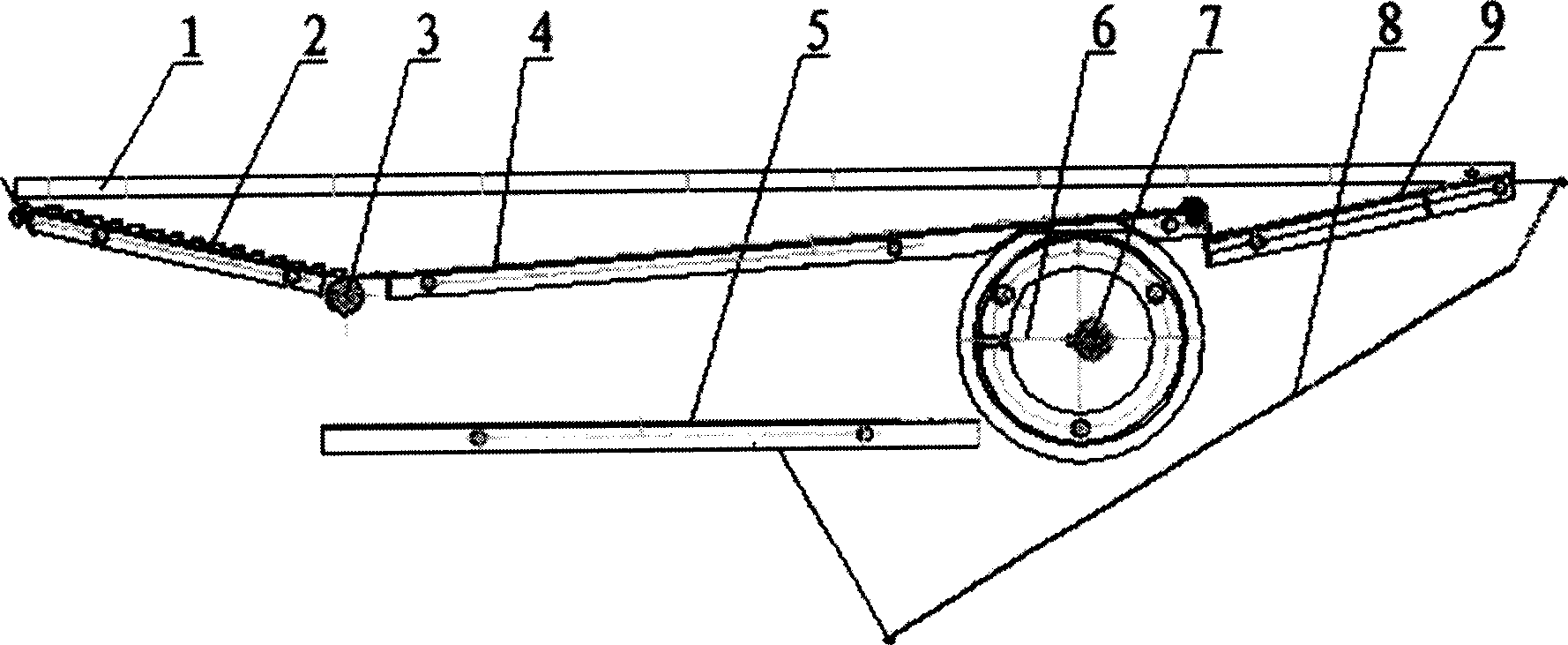

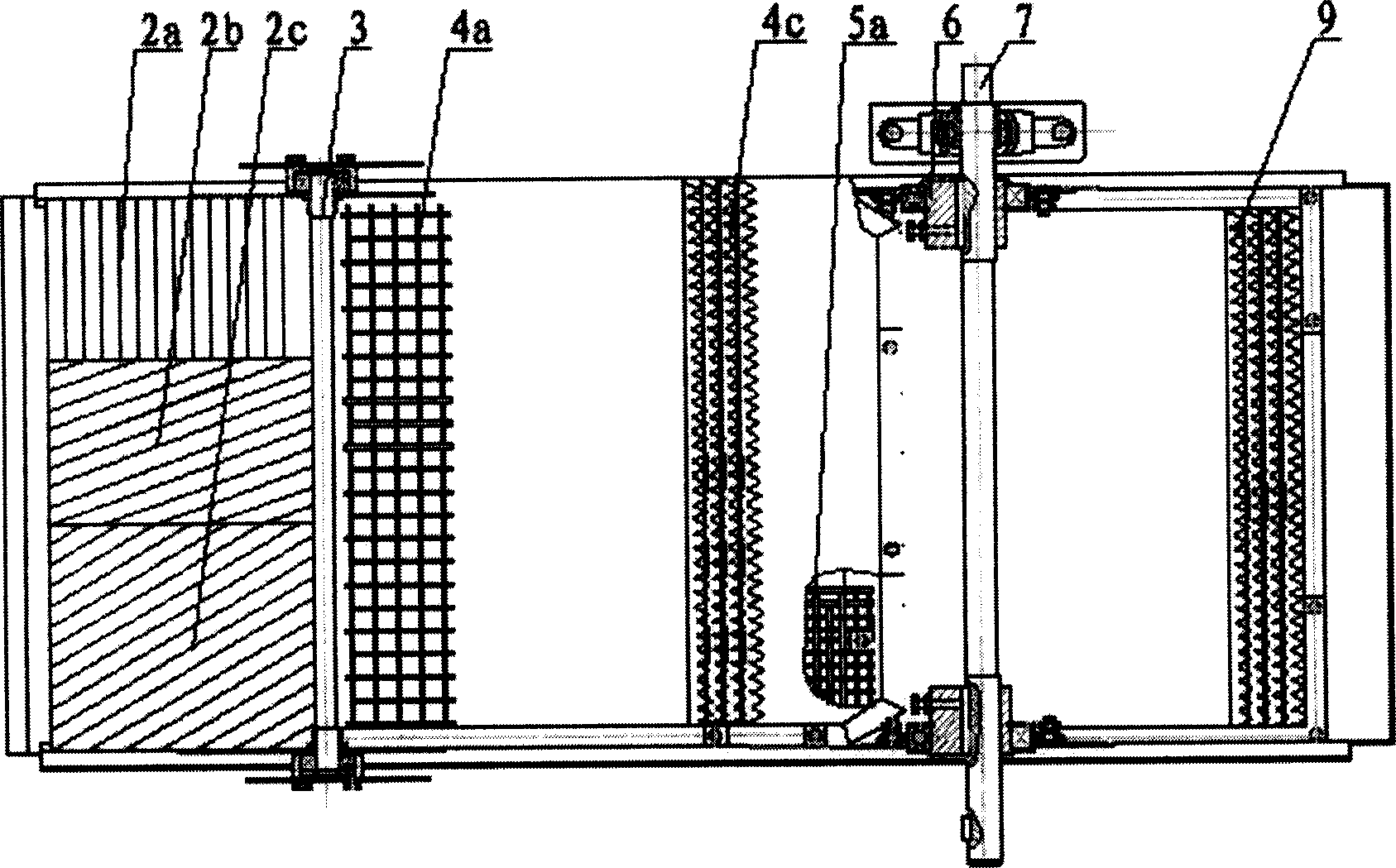

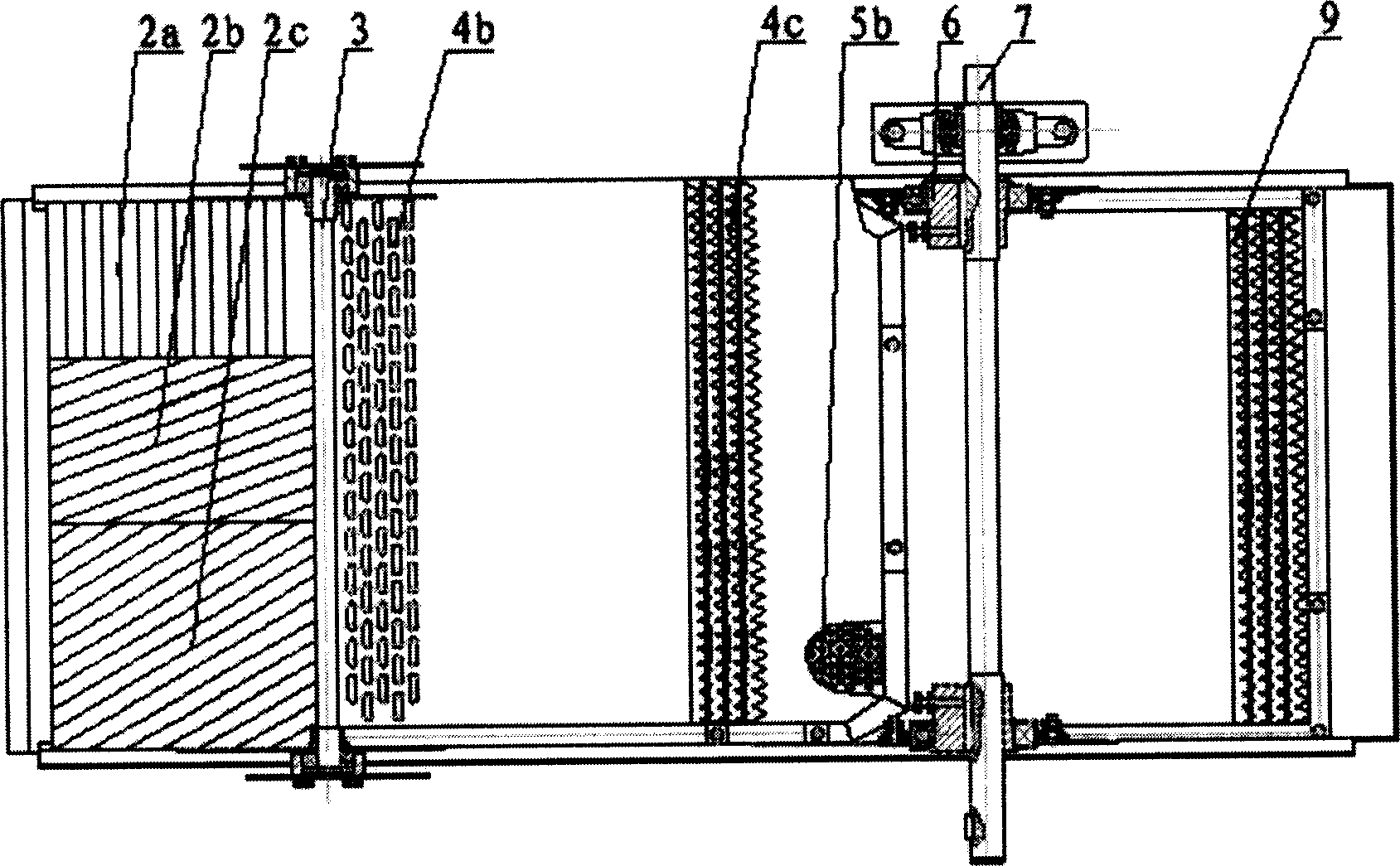

[0012] A vibrating cleaning screen of the present invention comprises a cleaning screen frame 1, a shaking plate 2, a front shaft 3, an upper screen 4, a lower screen 5, an eccentric block 6, a driving shaft 7, a slide plate 8 and a tail screen 9. Shaking plate 2, upper sieve 4, lower sieve 5 and tail sieve 9 are installed on the cleaning screen frame 1, such as figure 1 shown. The shaking plate 2 is composed of three different corrugated plates. The corrugated plate 2c near the feeding entrance has a corrugated angle 10° larger than that of the middle 2b. The corrugated angle of the third plate 2a is 90°. When cleaning rice, the upper sieve 4 uses The front weaving screen 4a, the rear fish scale screen 4c structure, the lower screen is a weaving screen 5a, and the tail screen 9 is a fish scale screen, such as figure 2 Shown; when cleaning rapeseed, the upper sieve 4 adopts the front punching sieve 4b, the rear fish-scale sieve 4c structure, the lower sieve is the punching s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com