Method for preparing wolfram steel or composite material of tungsten and silver

A preparation process and composite material technology, which is applied in the field of preparation technology of tungsten-copper or tungsten-silver composite materials, can solve the problems of hard phase-tungsten, such as poor particle roundness, high inclusion content, difficult distribution, etc. , to achieve the effect of reducing the arc erosion rate, weakening the splash, and avoiding the inhomogeneity of the structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

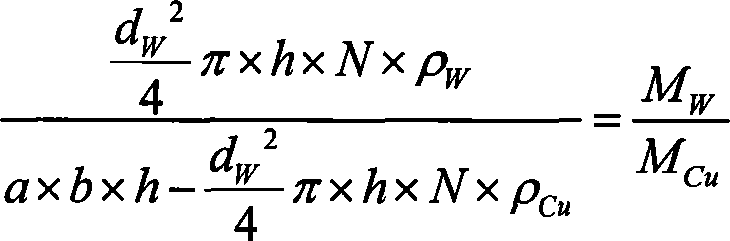

[0044] See Figure 2 for the process of preparing Cu40W60 cathode material contacts.

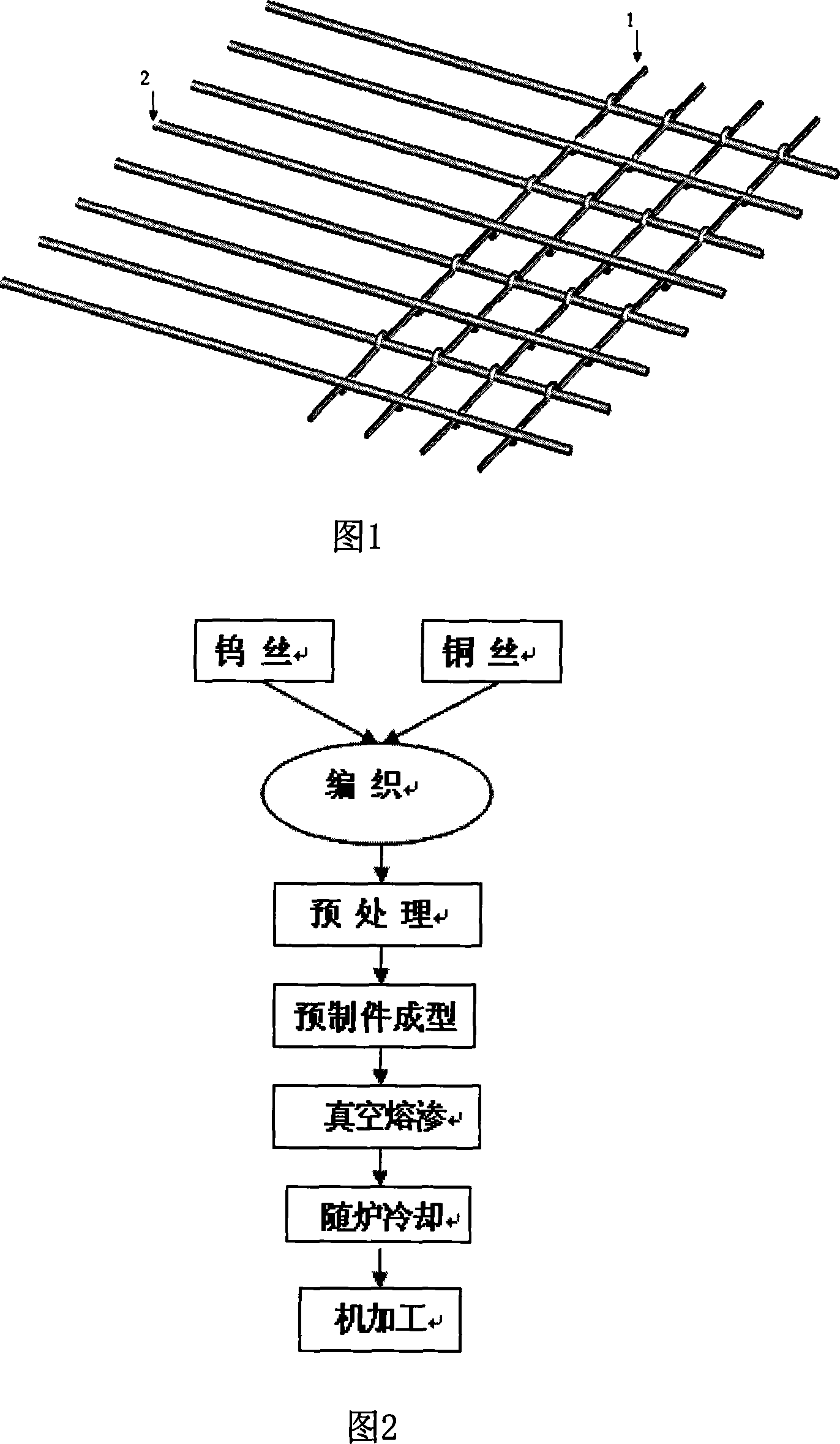

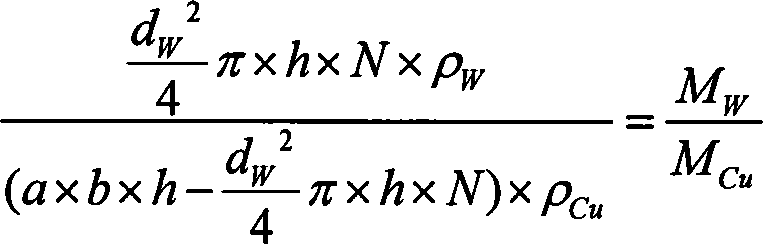

[0045] (1) Select tungsten wire with a diameter of 100-120μm, and pickling and cleaning, assuming d w =100μm, the prepared sample size is 4cm×4cm×3cm, and the required tungsten wire is calculated by formula ① to be 85×10 3 root, braiding a two-dimensional mesh (as shown in Figure 1); the copper wire needs very little, and is mainly used to induce copper liquid during auxiliary weaving and infiltration;

[0046] (2) According to the size required by the working conditions, cut the tungsten copper mesh into 4cm×3cm mesh;

[0047] (3) Stack, press and bundle the cut mesh pieces;

[0048] (4) Place the preform vertically in a vacuum furnace, place a copper ingot above it, and control the vacuum degree in the furnace to 1×10 -4Pa, then heat, the infiltration temperature is 1250°C, and the holding time is 3 hours, so that the molten copper fully penetrates into the gap between the tungsten wires...

Embodiment 2

[0052] See Figure 2 for the process of preparing Cu30W70 cathode material contacts.

[0053] (1) Select a tungsten wire with a diameter of 80-100 μm, and pickle and clean it, assuming d w =100μm, the prepared sample is 4cm×4cm×3cm, and the required tungsten wire is calculated by formula ① to be 106×10 3 root, braiding a two-dimensional mesh (as shown in Figure 1); the copper wire needs very little, and is mainly used to induce copper liquid during auxiliary weaving and infiltration;

[0054] (2) According to the size required by the working conditions, cut the tungsten copper mesh into 4cm×3cm mesh;

[0055] (3) Stack, press and bundle the cut mesh pieces;

[0056] (4) Place the preform vertically in a vacuum furnace, place a copper ingot above it, and control the vacuum degree in the furnace to 1×10 -4 Pa, then heat, the infiltration temperature is 1350°C, and the holding time is 3.5 hours, so that the molten copper fully penetrates into the gap between the tungsten wires;...

Embodiment 3

[0060] See Figure 2 for the process of preparing Ag40W60 cathode material contacts.

[0061] (1) Select tungsten wire with a diameter of 100-120μm, and pickling and cleaning, assuming d w =100μm, the prepared sample is 4cm×4cm×3cm, and the tungsten wire required by formula ① is 92×10 3 root, weave a two-dimensional net (as shown in Figure 1); the silver wire needs very little, and is mainly used to induce silver liquid during auxiliary weaving and infiltration;

[0062] (2) According to the size required by the working conditions, cut the tungsten silver mesh into a length of 4cm×3cm;

[0063] (3) Stack, press and bundle the cut mesh pieces

[0064] (4) Place the preform vertically in a vacuum furnace, place silver ingots above it, and control the vacuum degree in the furnace to 1.5×10 -4 Above Pa, then heat, the heating rate is 3-10°C / min, the infiltration temperature is 1150°C, and the holding time is 2 hours, so that the melted silver liquid can fully penetrate into the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com