Preparation method of large-diameter aluminum alloy tube

An aluminum alloy, large-diameter technology, applied in the field of preparation, can solve the problems of difficulty in obtaining large-diameter rotary billets, reduced mechanical properties, shortened production cycle, etc., and achieves the effect of avoiding mechanical properties degradation, improving mechanical properties, and shortening production cycle.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0013] Embodiment 1: This embodiment is a preparation method of a large-diameter aluminum alloy pipe, which is specifically completed according to the following steps:

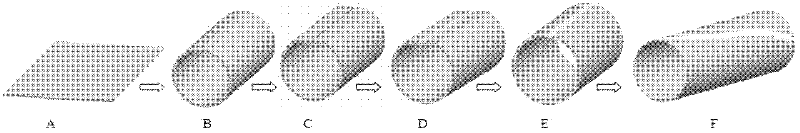

[0014] 1. Blanking: choose the thickness as t 0 The aluminum alloy rolled plate is cut by a shearing machine to obtain a rectangular or square aluminum alloy rolled plate; 2. Rolling: Use a plate rolling machine to roll the rectangular or square aluminum alloy rolled plate obtained in step 1 to obtain a round shape. Cylindrical tube blank; 3. Clamping: use a fixture to mount the butt joint of the cylindrical tube blank obtained in step 2 into a plane with a width of 20mm~Dmm, and ensure that the two ends of the butt joint are completely aligned face to face, and the gap is 10μm~ 100 μm, that is, the tube blank to be welded is obtained; 4. Welding: adopt the method of friction stir welding to weld the butt joint of the tube blank to be welded in step 3 to obtain a welded pipe; ;6. Thinning and spinning: the th...

specific Embodiment approach 2

[0036] Embodiment 2: The difference between this embodiment and Embodiment 1 is that the clamp described in step 3 is combined with Image 6 It consists of left support 1, left pressing claw 2, left pressing bolt 3, left push rod 7, right support 6, right pressing claw 5, right pressing bolt 4, right push rod 8, fixture base 9, mandrel 10 and The cushion block 11 is composed of, among which the fixture base 9 is composed of the bottom plate 9-1, the left baffle 9-2, the right baffle 9-3 and the rear baffle 9-4, the left support 1 and the left push rod 7 and the left baffle 9-2 is connected, and the left support 1 and the left push rod 7 can repeatedly move left and right on the left baffle 9-2, the right support 6 and the right push rod 8 are connected with the right baffle 9-3, and the right support 6 and the right The push rod 8 can repeatedly move left and right on the right baffle 9-3, the mandrel 10 is connected with the rear baffle 9-4, and the mandrel 10 is fixed along ...

specific Embodiment approach 3

[0037] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is that the clamping process described in step 3 is as follows: the cylindrical pipe obtained in step 2 is sleeved on the mandrel 10, and the adjustment step 2 The obtained cylindrical pipe makes the cylindrical pipe butt in the gap between the left pressing claw 2 and the right pressing claw 5, and then adjust the spacer 11 so that the arc bottom of the mandrel 10 and the inner wall of the cylindrical pipe obtained in step 2 are sufficient. Contact, and then adjust the cylindrical pipe obtained in step 2 through the left support 1, the left push rod 7, the right support 6, and the right push rod 8, and finally use the left pressing claw 2, left pressing bolt 3, right pressing claw 5 and the right pressing bolt 4 to press the two sides of the butt joint of the cylindrical pipe against the mandrel 10, and finally the pipe blank to be welded is obtained. Others are the same as in the first or secon...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com